Application of beta-glucan as adhesive in preparation of tablets or granules

A technology of glucan and granules, applied in the field of β-glucan tablets and its preparation, can solve the problems of poor compressibility, uneven mixing, inability to fully absorb, etc., to improve uniformity and consistency, prescription Simple composition, enhanced dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

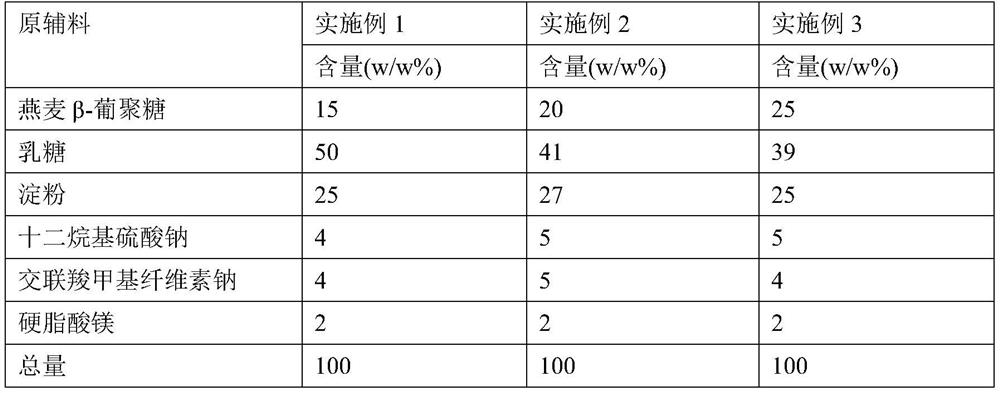

Embodiment 1-3

[0034]

[0035] Preparation:

[0036] 1) Disperse β-glucan in ethanol with a weight to volume ratio of 50% (w / v), and stir at 3500rmp for 2 hours to form a β-glucan-ethanol mixture.

[0037] 2) Add the surfactant sodium lauryl sulfate to the above mixture, stir thoroughly, boil and dry at 70°C for 2 hours, measure the loss on drying to 1.0%, and obtain β-glucan-sodium lauryl sulfate powder .

[0038] 3) Jet milling the β-glucan-sodium dodecyl sulfate powder to obtain a modified powder of β-glucan-sodium dodecyl sulfate.

[0039] 4) dry granulate after mixing the above-mentioned β-glucan-sodium lauryl sulfate modified powder with lactose, starch, and cross-linked carmellose sodium,

[0040] 5) The above particles are mixed with a lubricant and then compressed into tablets, the tableting speed is 20-60rmp, and the tablet core hardness is 4-9kp.

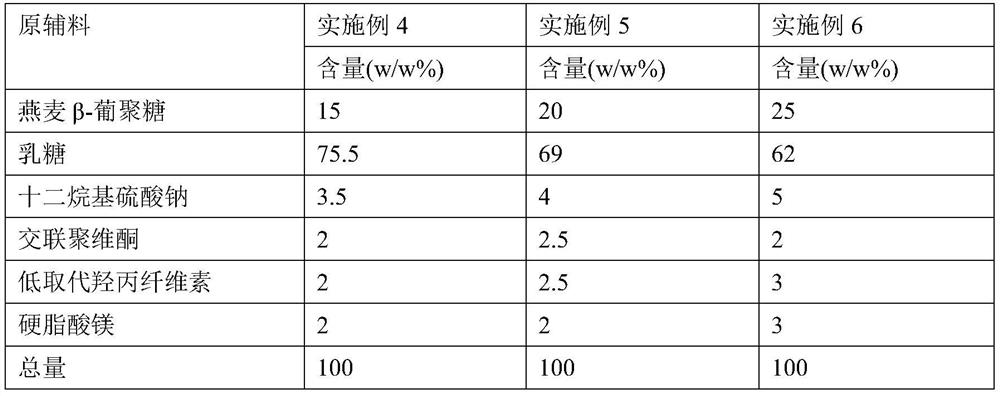

Embodiment 4-6

[0042]

[0043] Preparation:

[0044] 1) Disperse β-glucan in acetone with a weight to volume ratio of 40% (w / v), and stir at 3500rmp for 2 hours to form a β-glucan-acetone mixture.

[0045] 2) Add the surfactant sodium lauryl sulfate to the above mixture, stir thoroughly, boil and dry at 70°C for 2 hours, measure the loss on drying to 1.0%, and obtain β-glucan-sodium lauryl sulfate powder .

[0046] 3) Jet milling the β-glucan-sodium dodecyl sulfate powder to obtain a modified powder of β-glucan-sodium dodecyl sulfate.

[0047] 4) Dry granulate the above-mentioned β-glucan-sodium lauryl sulfate modified powder with lactose, crospovidone and low-substituted hydroxypropyl cellulose,

[0048] 5) The above particles are mixed with a lubricant and then compressed into tablets, the tableting speed is 20-60rmp, and the tablet core hardness is 4-9kp.

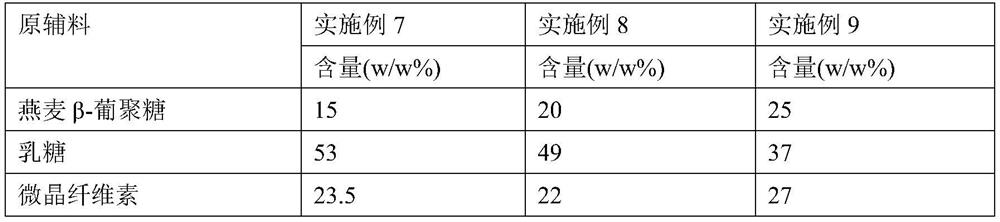

Embodiment 7-9

[0050]

[0051]

[0052] Preparation:

[0053] 1) Disperse β-glucan in ethanol with a weight to volume ratio of 50% (w / v), and stir at 3500rmp for 2 hours to form a β-glucan-ethanol mixture.

[0054] 2) Add the surfactant sodium lauryl sulfate to the above mixture, stir thoroughly, boil and dry at 70°C for 2 hours, measure the loss on drying to 1.0%, and obtain β-glucan-sodium lauryl sulfate powder .

[0055] 3) Jet milling the β-glucan-sodium dodecyl sulfate powder to obtain a modified powder of β-glucan-sodium dodecyl sulfate.

[0056] 4) dry granulate after mixing the above-mentioned β-glucan-sodium lauryl sulfate modified powder with lactose, microcrystalline cellulose, and cross-linked carmellose sodium,

[0057] 5) The above particles are mixed with magnesium stearate and then compressed into tablets, the tablet compression speed is 20-60rmp, and the tablet core hardness is 4-9kp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com