Covalent organic framework material and its preparation method and application

A technology of covalent organic frameworks and products, applied in the direction of luminescent materials, chemical instruments and methods, identification devices, etc., to achieve the effect of simple preparation method, high yield, good chemical and physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Based on this, an embodiment of the present invention also provides a method for preparing a covalent organic framework material, comprising the following steps:

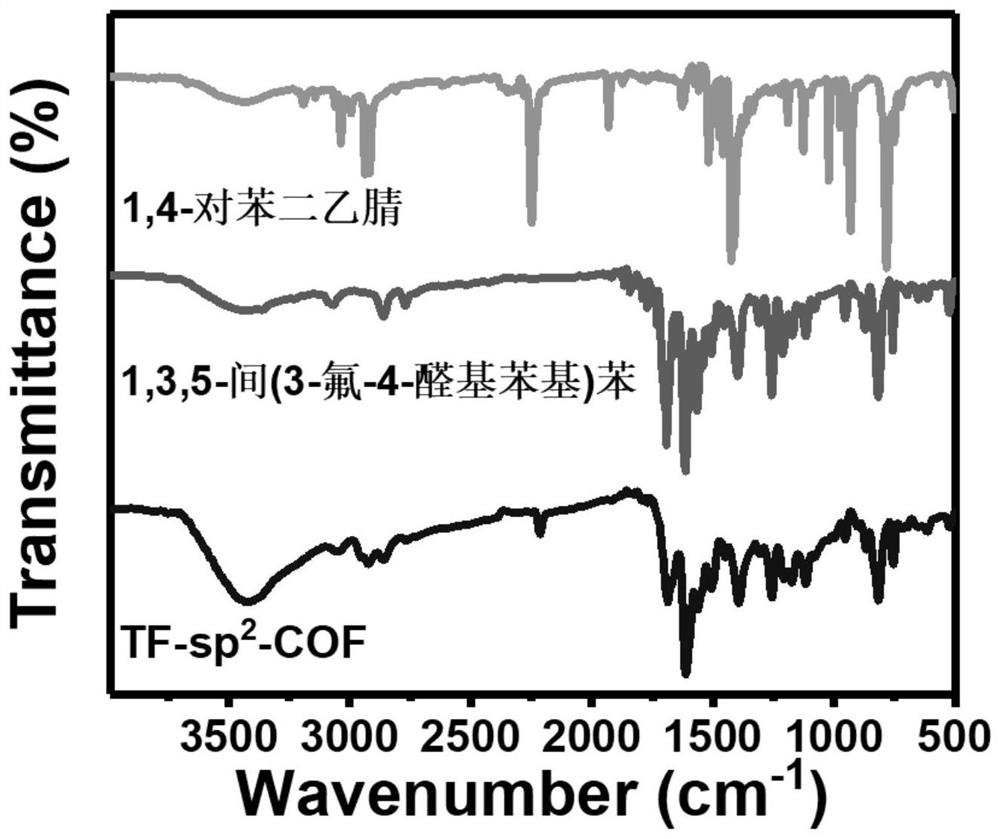

[0046] 1,3,5-m-(3-fluoro-4-formylphenyl)benzene, 1,4-terephthalonitrile and a catalyst are mixed in a solvent, and the resulting mixture is subjected to deoxygenation treatment, followed by solvothermal reaction.

[0047] The above preparation method adopts the solvothermal reaction of the monomer 1,3,5-m-(3-fluoro-4-formylphenyl)benzene and 1,4-terephthalonitrile in a solvent in the presence of a catalyst, by Simple steps to prepare covalent organic framework materials, the cost of synthetic equipment and medicines involved is low, and the synthesis method has high yield (~90%), high monomer utilization rate, and no environmentally harmful small molecular substances are produced, which is environmentally friendly .

[0048] In one specific embodiment, the solvent is n-butanol, or a mixture of n-butanol and ...

Embodiment 1

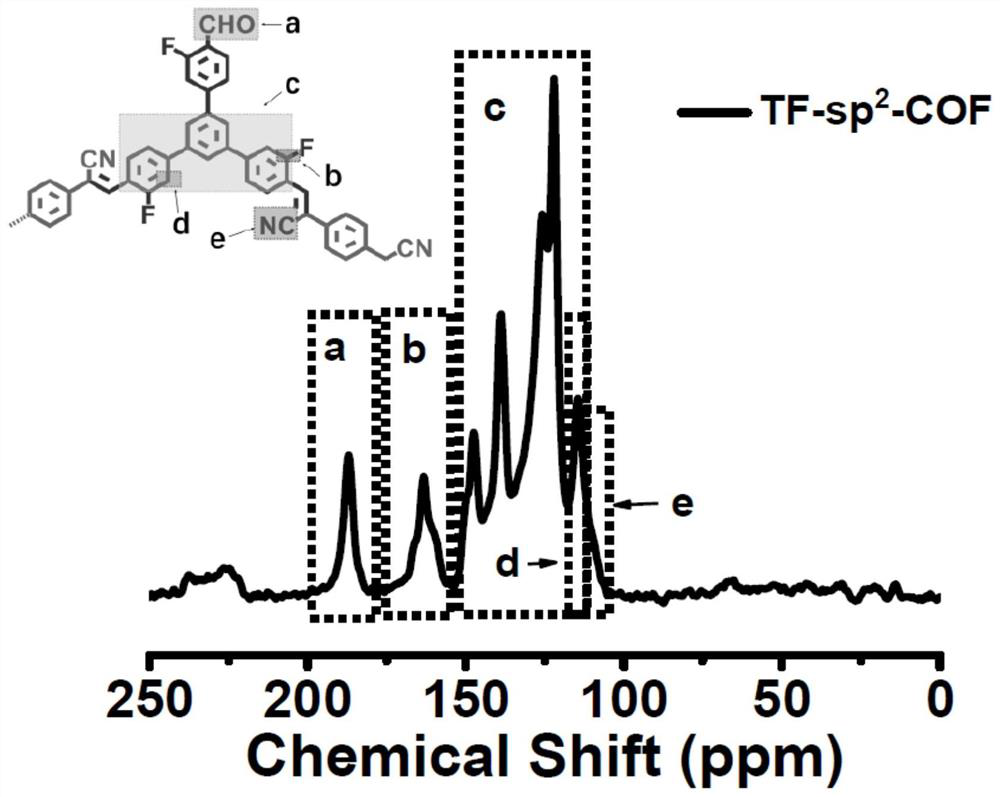

[0062] This embodiment provides a solvothermal preparation method of a covalent organic framework material, the covalent organic framework material (TF-sp 2 -COF) has the following structural features:

[0063]

[0064] Described preparation method comprises the steps:

[0065] (1) Weigh 57mg 1,3,5-m-(3-fluoro-4-formylphenyl)benzene, 15mg 1,4-terephthalonitrile and 42.03mg cesium carbonate, and disperse them in 2mL o-dichlorobenzene In the mixed solution of n-butanol (volume ratio 1:1), the oxygen and dissolved oxygen in the above mixed system are removed by freezing and thawing and deoxygenation;

[0066] (2) After the reaction system is completely thawed after the above-mentioned freezing and thawing cycle to remove oxygen, heat and stir in a metal bath at 120°C for 72 hours;

[0067] (3) The obtained product is cooled to room temperature, washed with tetrahydrofuran, dichloromethane, acetone, ethanol and deionized water respectively to obtain a yellow powdery product, ...

Embodiment 2

[0072] This embodiment provides the covalent organic framework material (TF-sp) described in embodiment 1 2 -COF) performance test.

[0073] 1. Crystallinity

[0074] The covalent organic framework material (TF-sp 2 -COF) powder X-ray diffraction spectrum as Figure 4 shown. Depend on Figure 4 It can be seen that the peak of the covalent organic framework material at about 2.7° is very sharp, corresponding to the diffraction peak of the (100) crystal plane, and two diffraction peaks appear at 4.6 and 7.1°, corresponding to the (110), (120) crystal plane, The advantage of the higher crystallinity of the covalent organic framework material is illustrated.

[0075] 2. Thermal stability

[0076] The covalent organic framework material (TF-sp 2 -COF) thermogravimetric analysis curve as Figure 5 shown. Depend on Figure 5 It can be seen that the weight loss of the covalent organic framework material is less than 10% at 542° C., indicating that the covalent organic framew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com