Method for rapidly growing metal single atoms on carbon-based carrier by using microwave to induce metal to discharge and application of metal monatomic carbon-based material prepared by method

A technology for inducing metal and carbon-based supports, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, metal material coating technology, etc., can solve high preparation costs, long sputtering time, equipment Requires high-level problems to achieve the effects of improved deposition efficiency, easier capture, and increased loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

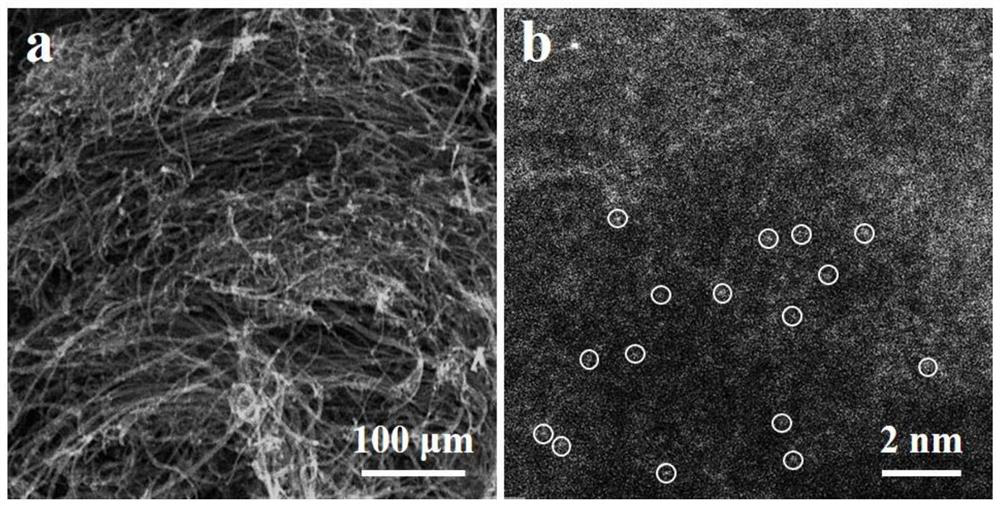

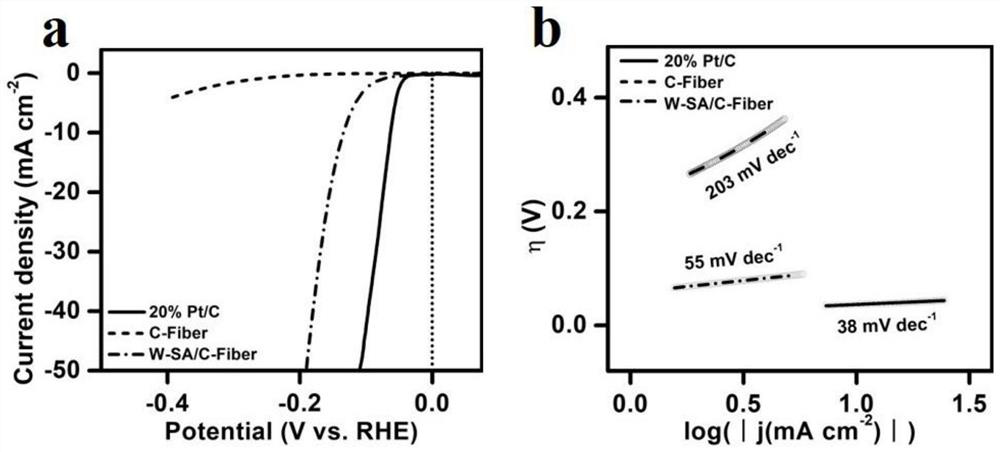

[0038] A method for rapidly growing tungsten metal single atoms on a carbon-based carrier by microwave-induced metal discharge, comprising the following steps:

[0039] S1. Add 200mg of conductive carbon fiber to 30mL of ethanol solvent, and use an ultrasonic cell pulverizer with a power of 600W to mix evenly for 60s to obtain a carrier solution; after the ethanol volatilizes until the solution becomes viscous (the concentration of conductive carbon fiber is about 20mg / mL) , use a brush to coat the viscous carrier solution on the wall of a 200mL quartz beaker, the thickness of the carrier coating is about 0.2cm;

[0040] Then polish the tungsten metal wire with a length of 5 cm and a diameter of 0.2 cm with sandpaper, and put it into the center of the bottom of the above-mentioned quartz beaker.

[0041] S2. Place the quartz beaker obtained in step S1 in a household microwave oven, continuously feed argon gas to carry out microwave treatment on the quartz beaker for about 120s...

Embodiment 2

[0044] A method for rapidly growing tungsten metal single atoms on a carbon-based carrier by microwave-induced metal discharge, comprising the following steps:

[0045] S1. Add 200mg of conductive carbon fiber and 10mg of urea to 30mL of ethanol solvent, and use an ultrasonic cell pulverizer with a power of 600W to mix evenly for 60s to obtain a carrier solution; after the ethanol volatilizes until the solution becomes viscous (the concentration of conductive carbon fiber is about 20mg / mL), the viscous carrier solution is coated on the cup wall of the 200mL quartz beaker with a brush, and the thickness of the carrier coating is about 0.2cm;

[0046] Then polish the tungsten metal wire with a length of 5 cm and a diameter of 0.2 cm with sandpaper, and put it into the center of the bottom of the above-mentioned quartz beaker.

[0047] S2. Place the quartz beaker obtained in step S1 in a household microwave oven, continuously feed argon gas to carry out microwave treatment on th...

Embodiment 3

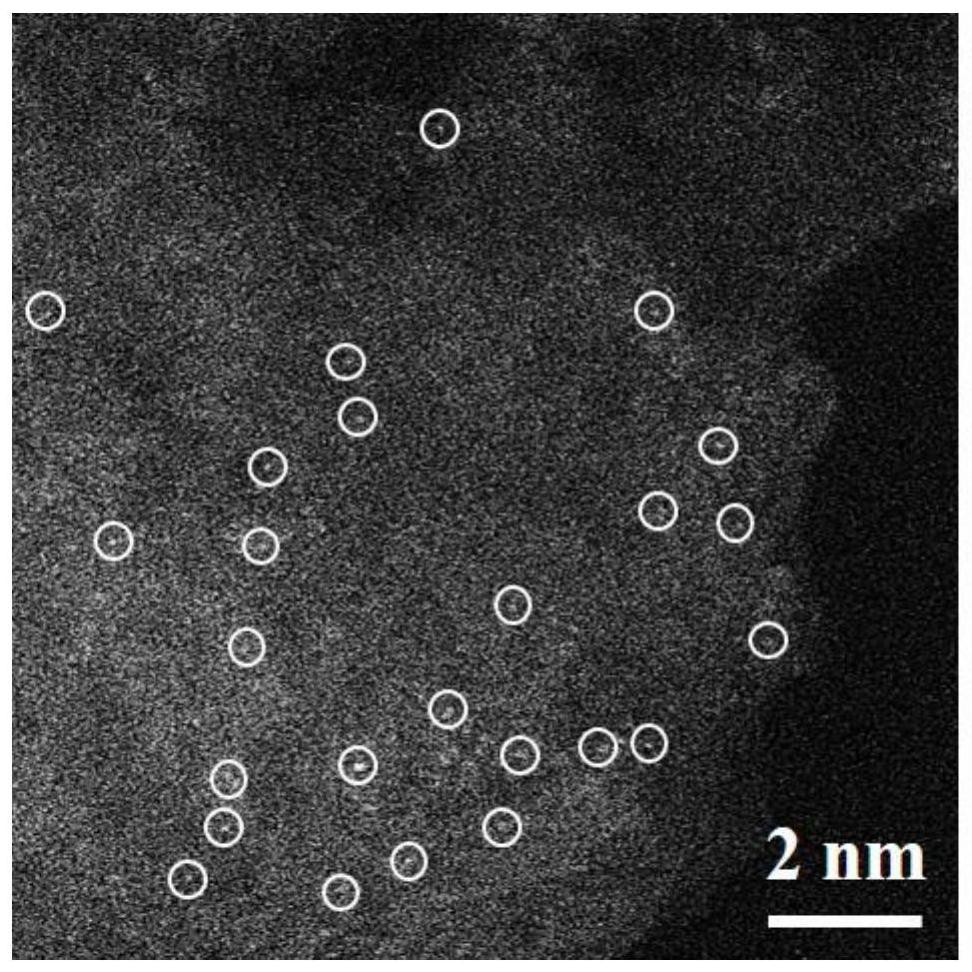

[0052] A method for rapidly growing molybdenum metal single atoms on a carbon-based carrier by microwave-induced metal discharge, comprising the following steps:

[0053] S1. Add 200mg of conductive carbon fiber and 10mg of urea to 30mL of ethanol solvent, and use an ultrasonic cell pulverizer with 600W power to mix evenly for 60s to obtain a carrier solution; after the ethanol volatilizes until the solution becomes viscous (the concentration of conductive carbon fiber is about 25mg / mL), the viscous carrier solution is coated on the cup wall of the 200mL quartz beaker with a brush, and the thickness of the carrier coating is about 0.1cm;

[0054] Then be long 5cm, the molybdenum metal wire that diameter is 0.2cm is polished bright with sandpaper, puts into the bottom center of above-mentioned quartz beaker;

[0055] S2. The quartz beaker obtained in step S1 is placed in a household microwave oven, and the argon gas is continuously fed into the quartz beaker to perform microwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com