Biomass cellulose modified PVDF hollow fiber microfiltration membrane as well as preparation method and application thereof

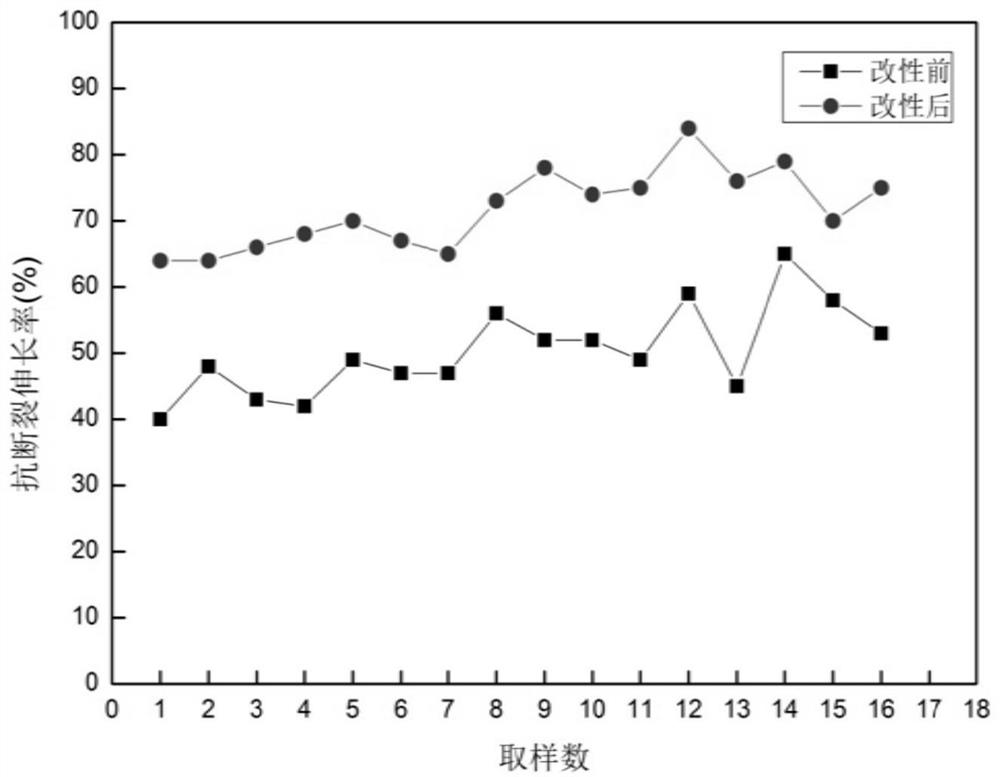

A biomass and cellulose technology, used in chemical instruments and methods, biological water/sewage treatment, membranes, etc., can solve the problems of easy detachment of carbon nanotube modified layers, and achieve good anti-pollution performance and anti-mechanical fracture performance. , The effect of low processing cost and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

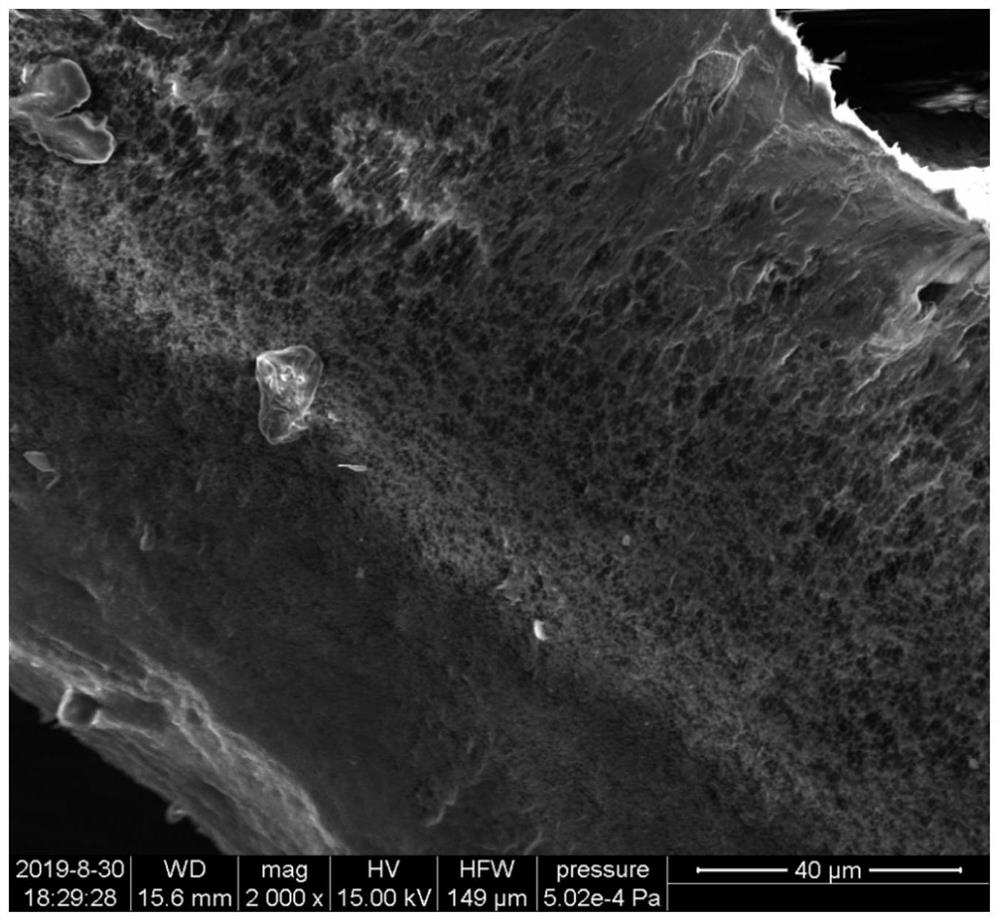

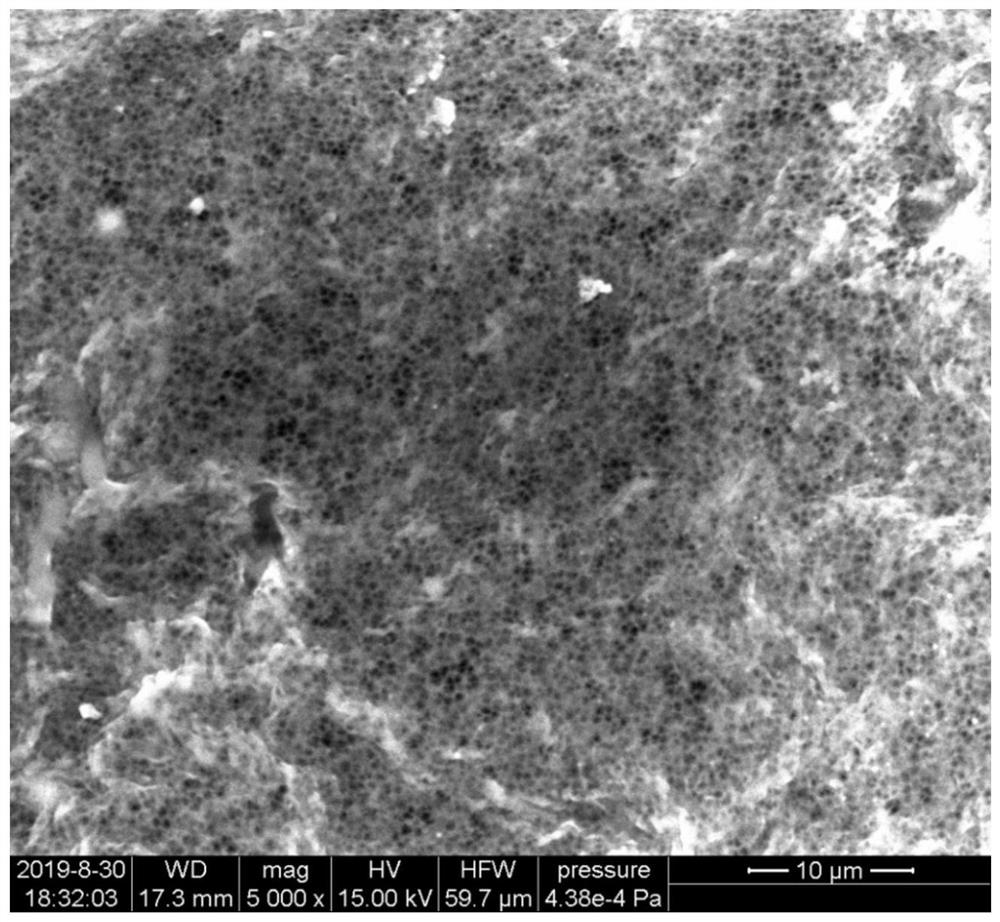

[0034] A preparation method of biomass cellulose modified PVDF hollow fiber microfiltration membrane, comprising the following steps:

[0035] (1) The biomass is made of tea dregs. After the tea dregs are crushed and washed with water, they are added to the acidic sodium chlorite solution for immersion treatment. The pH of the acidic sodium chlorite solution is adjusted to 3 with nitric acid, and the temperature of immersion is 100°C. 30min; after the impregnation, wash it with 95% ethanol solution to obtain biomass crude cellulose; take the above biomass crude cellulose and place it in a sodium hydroxide solution with a mass concentration of 2% and heat it to 100°C for alkali treatment After 30 minutes, the hemicellulose was removed to obtain biomass cellulose, which was dried and used for later use.

[0036] (2) Add biomass cellulose to DMAC, and add LiCl, the dosage of LiCl is 60g / L; ultrasonic 6h under the condition of ultrasonic power 100W at 80°C to fully disperse the bi...

Embodiment 2

[0050] A preparation method of biomass cellulose modified PVDF hollow fiber microfiltration membrane, comprising the following steps:

[0051] (1) The biomass is made of tea dregs. After the tea dregs are crushed and washed with water, they are added to an acidic sodium chlorite solution for immersion treatment. The pH of the acidic sodium chlorite solution is adjusted to 4 with nitric acid, and the temperature of immersion is 100°C. After immersion, wash it with 95% ethanol solution to obtain biomass crude cellulose; take the above biomass crude cellulose and place it in 2% sodium hydroxide solution with a mass concentration of 2% and heat it to 100°C for alkali treatment for 30 minutes to remove Biomass cellulose is obtained after hemicellulose is dried for use.

[0052] (2) Add biomass cellulose to DMAC, and add LiCl, the dosage of LiCl is 60g / L, ultrasonic 6h under the condition of ultrasonic power 100W at 80°C to fully disperse the biomass cellulose in DMAC to obtain fibe...

Embodiment 3

[0061] A preparation method of biomass cellulose modified PVDF hollow fiber microfiltration membrane, comprising the following steps:

[0062] (1) The biomass is made of tea dregs. After the tea dregs are crushed and washed with water, they are added to the acidic sodium chlorite solution for immersion treatment. The pH of the acidic sodium chlorite solution is adjusted to 3.5 with nitric acid, and the temperature of the immersion is 100°C. After the impregnation, it was washed with 95% ethanol solution to obtain biomass crude cellulose; the above biomass crude cellulose was placed in a 2% sodium hydroxide solution and heated to 120°C for alkali treatment for 50 minutes. After removing the hemicellulose, the biomass cellulose is obtained, which is dried for use.

[0063] (2) Add biomass cellulose to DMAC, and add LiCl, the dosage of LiCl is 60g / L, ultrasonic 6h under the condition of ultrasonic power 100W at 80°C to fully disperse the biomass cellulose in DMAC to obtain fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com