Sludge carbon-based ozone catalyst and preparation method thereof

The technology of sludge charcoal and catalyst is applied in the field of sludge charcoal-based ozone catalyst and its preparation, which can solve the problem of high production cost and achieve the effects of long service life, low raw material cost and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

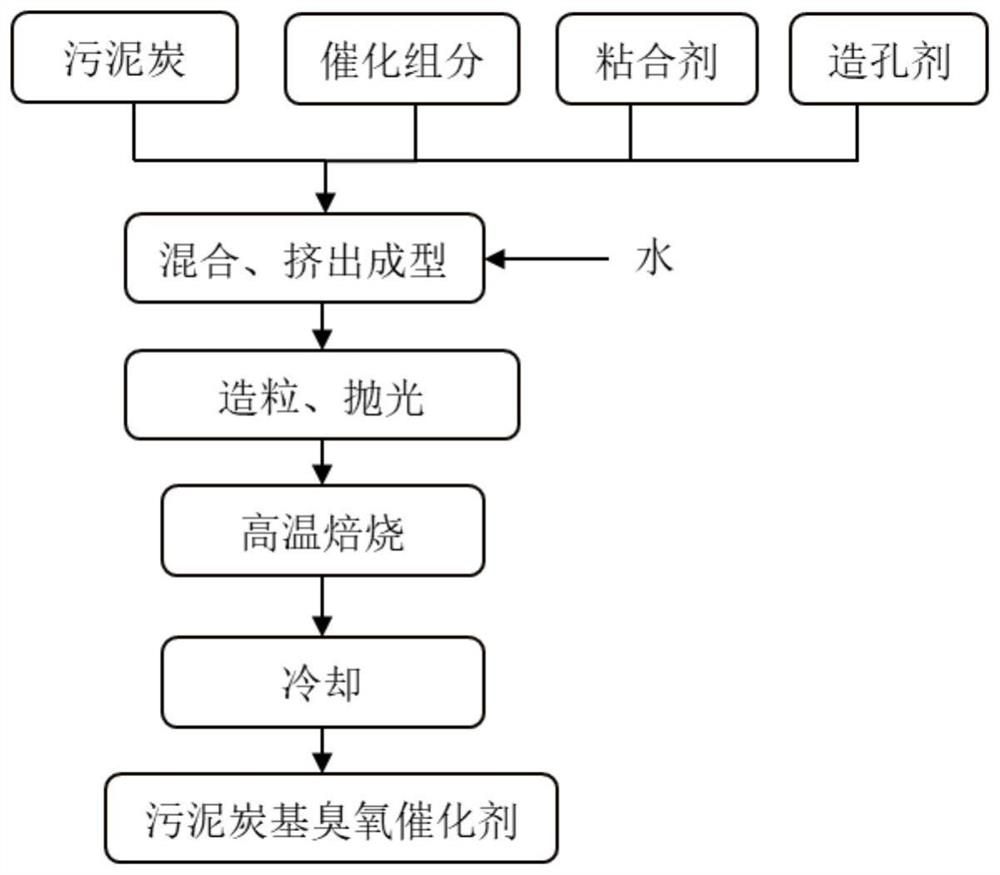

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix the powder raw materials such as sludge charcoal, fine iron powder, bentonite, gas-forming powder, copper powder and manganese acetate according to the mass ratio of 54:32:8:10:9:5.

[0038] (2) Add an appropriate amount of water to stir and mix, extrude through a screw extruder and polish to make raw meal balls with a particle size of about 6-8mm.

[0039] (3) After the raw material balls are air-dried at room temperature, they are dried in a blast drying oven at 110°C.

[0040](4) Put the dried raw material balls into the resistance furnace, set the heating rate to 10°C / min, keep warm for 1h when the temperature rises to 600°C, then continue to heat up and roast in the resistance furnace at 1160°C for 40min to make sintered dirt Peat based ozone catalyst.

[0041] Take 200mL of biochemical tail water from a sewage treatment plant, the amount of catalyst is 25g, the aeration contact time is 1h, the gas flow rate at the outlet of the ozone generator is 0.1L / min...

Embodiment 2

[0046] (1) Mix powdered sludge charcoal, fine iron powder, bentonite, gas-forming powder and nickel oxide evenly according to the mass ratio of 54:32:15:10:5.

[0047] (2) Add an appropriate amount of water to stir and mix, extrude through a screw extruder and polish to make raw meal balls with a particle size of about 6-8mm.

[0048] (3) After the raw meal balls are air-dried at room temperature, they are dried in a blast drying oven at 105°C.

[0049] (4) Put the dried raw meal balls into the resistance furnace, set the heating rate to 10°C / min, heat it up to 600°C for 1 hour, then continue to heat up and bake at 1120°C for 60 minutes in the resistance furnace to make sintered sludge Carbon based ozone catalyst.

[0050] Take 200mL of biochemical tail water from a sewage treatment plant, the amount of catalyst is 25g, the aeration contact time is 1h, the gas flow rate at the outlet of the ozone generator is 0.1L / min, the ozone contact time is 1h, and the ozone dosage is abo...

Embodiment 3

[0052] (1) Mix powdered sludge carbon, alumina, bentonite, nickel oxide, manganese dioxide, and ammonium bicarbonate evenly according to the mass ratio of 80:40:10:5:10:2.

[0053] (2) Add an appropriate amount of water to stir and mix, extrude through a screw extruder and polish to make raw meal balls with a particle size of about 6-8mm.

[0054] (3) After the raw material balls are air-dried at room temperature, they are dried in a blast drying oven at 115°C.

[0055] (4) Put the dried raw meal balls into the resistance furnace, set the heating rate to 10°C / min, keep warm for 1h when the temperature rises to 600°C, then continue to heat up and roast at 1000°C for 60min in the resistance furnace to make sintered sludge Carbon based ozone catalyst.

[0056] Take 200mL of biochemical tail water from a sewage treatment plant, the amount of catalyst is 25g, the aeration contact time is 1h, the gas flow rate at the outlet of the ozone generator is 0.1L / min, the ozone contact time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com