Preparation method of road dust suppression film-forming agent and water-resoluble road dust suppression film-forming agent

A film-forming agent, road technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems affecting the visual cleanliness and flushability of the road surface, and achieve the effect of safety in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 60 parts of deionized water and 13 parts of acrylic acid into the reaction kettle, and stir rapidly for 10 minutes; dissolve 8 parts of sodium hydroxide with 50 parts of deionized water, then add the aqueous sodium hydroxide solution into the reaction kettle, and stir for 30 minutes; add 11 parts of vinyl acetate , 2 parts of ethyl acrylate, and 8 parts of methyl acrylate were mixed and slowly added to the reactor, and stirred for 10 minutes; the reaction temperature was raised to 72°C; 0.7 parts of ammonium persulfate was dissolved in 26 parts of deionized water, and it was added to the reactor for 65 minutes, and Gradually raise the temperature to 85°C and react for 1h; continue to raise the temperature to 95°C and react for 1h; cool down to room temperature and discharge.

Embodiment 2

[0029] Add 45 parts of deionized water, 7 parts of acrylic acid, and 15 parts of maleic anhydride into the reactor, and stir rapidly for 20 minutes; dissolve 10 parts of sodium hydroxide with 60 parts of deionized water, then add the aqueous sodium hydroxide solution into the reactor, and stir 40min; Mix 10 parts of vinyl acetate, 2 parts of methyl acrylate, 5 parts of ethyl acrylate, and 3 parts of hydroxypropyl acrylate, then slowly add to the reaction kettle and stir for 30 minutes; raise the reaction temperature to 75 ° C; use 30 parts to remove Dissolve 0.8 parts of potassium persulfate in deionized water, add it to the reaction kettle after 1.5 hours, and gradually raise the temperature to 88°C, react for 2h; continue to raise the temperature to 93°C, react for 1h; cool down to room temperature and discharge.

Embodiment 3

[0031] Add 55 parts of deionized water and 17 parts of maleic anhydride into the reactor, and stir rapidly for 15 minutes; dissolve 7 parts of sodium hydroxide with 25 parts of deionized water, then add the aqueous sodium hydroxide solution into the reactor, and stir for 30 minutes; Parts of vinyl acetate, 3 parts of ethyl acrylate, and 7 parts of hydroxyethyl acrylate were mixed and slowly added to the reaction kettle, stirred for 20 minutes; the reaction temperature was raised to 72°C; 0.7 parts of potassium persulfate was dissolved in 20 parts of deionized water, 10 0.2 parts of deionized water diluted with 0.2 parts of H 2 o 2 , it takes 80 minutes to add to the reactor, and react for 1 hour; continue to heat up to 85°C, and react for 1 hour; continue to heat up to 95°C, and react for 1 hour; cool down to room temperature and discharge.

PUM

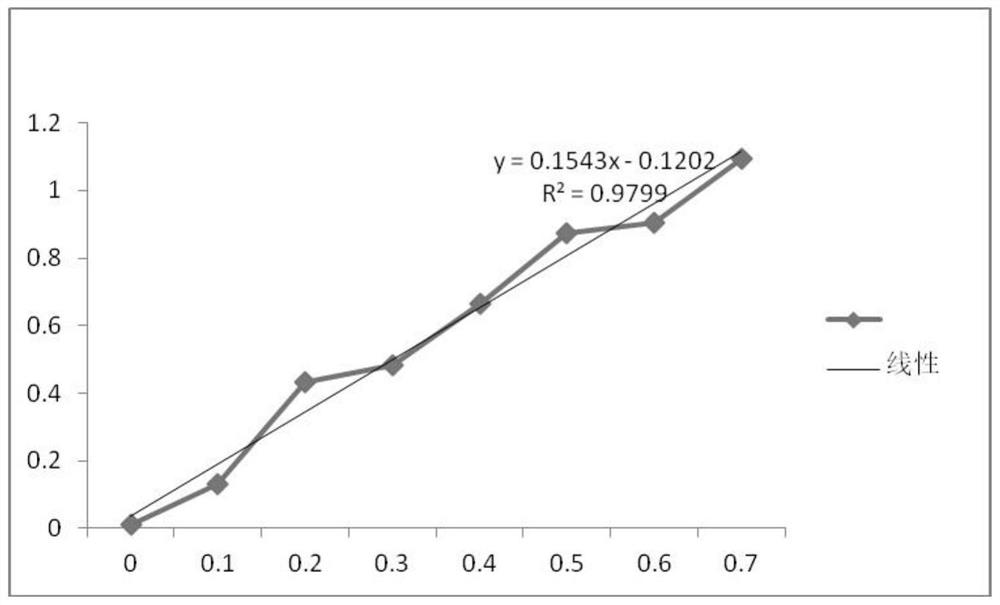

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com