Diluted hydrochloric acid and hydrogen sulfide corrosion resistant oil-refining distillation tower top corrosion inhibitor

A technology of hydrogen sulfide and dilute hydrochloric acid, applied in the direction of preventing corrosion during distillation, can solve problems such as affecting development and application, and being unfriendly to the environment, and achieve good anti-corrosion effect, good corrosion inhibition effect, and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

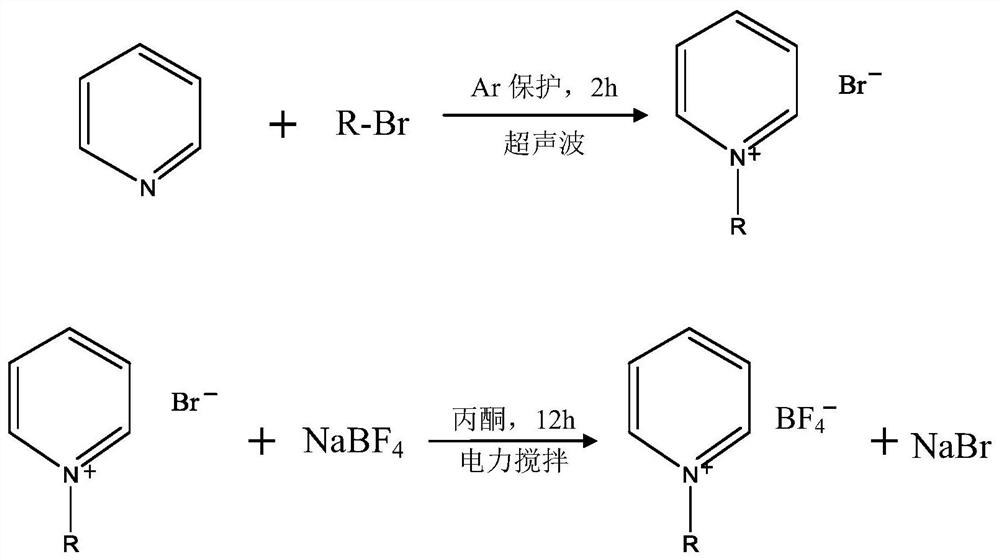

[0044]N-Alkylpyridine tetrafluoroborate is prepared by the following process: Add a certain amount of methyl bromide (33mmol) into a three-neck round bottom flask, install a constant pressure dropping funnel with 30mmol of pyridine and a condensing reflux with a drying tube The device, fixed on the upper end of the transducer of the ultrasonic cleaner, starts ultrasonication, drops pyridine at a rate of 10mL / min, and reacts for 5 minutes in the Ar protection ultrasonic intermittent operation mode. , The reaction was stopped after 1.8h of reaction, and a light yellow solid was obtained by filtration. Add the light yellow solid, 31.5 mmol of sodium tetrafluoroborate (NaBF4) and 54 mmol of acetone into a single-necked round-bottomed flask with a condensing reflux device, and react with magnetic stirring for 11 hours at room temperature, then filter to remove the white precipitate NaBr, and add 20 mL of NaBr to the filtrate Dichloromethane produced white precipitate, filtered, and...

Embodiment 2

[0047] N-Alkylpyridine tetrafluoroborate is prepared by the following process: Add a certain amount of n-butane bromide (33mmol) into a three-necked round-bottomed flask, a constant pressure dropping funnel with 30mmol pyridine and a drying tube Condensation and reflux device, fixed on the upper end of the transducer of the ultrasonic cleaner, start ultrasonication, slowly add pyridine dropwise at a rate of 10mL / min, and Ar protection ultrasonic intermittent operation mode. A solid was formed, and the reaction was stopped after 2 hours of reaction, and a light yellow solid was obtained by filtration. The pale yellow solid was mixed with 31.5mmol sodium tetrafluoroborate (NaBF 4 ) and 54mmol of acetone were added to a single-necked round-bottomed flask with a condensing reflux device, and filtered under magnetic stirring at room temperature for 12 hours to remove the white precipitate NaBr, and 20 mL of dichloromethane was added to the filtrate to form a white precipitate, whic...

Embodiment 3

[0050] N-Alkylpyridine tetrafluoroborate is prepared by the following process: Add a certain amount of bromododecane (39mmol) into a three-necked round-bottomed flask, a constant pressure dropping funnel with 30mmol pyridine and a drying tube Condensation and reflux device, fixed on the upper end of the transducer of the ultrasonic cleaner, start ultrasonication, drop pyridine at a rate of 8mL / min, and Ar protection ultrasonic intermittent operation mode. After 2.2 hours of reaction, the reaction was stopped, and a light yellow solid was obtained by filtration. The pale yellow solid was mixed with 34.5mmol sodium tetrafluoroborate (NaBF 4 ) and 60mmol of acetone were added to a single-necked round-bottomed flask with a condensing reflux device, filtered under magnetic stirring at room temperature for 13 hours, and the white precipitate NaBr was removed, and 30 mL of dichloromethane was added to the filtrate to form a white precipitate, which was filtered and removed by rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com