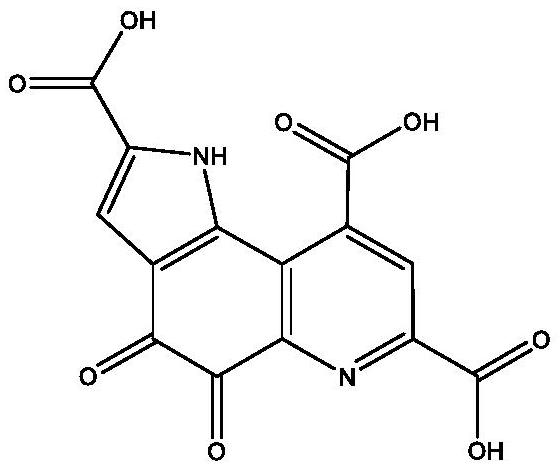

Method for separating and purifying pyrroloquinoline quinone

A technology for separation and purification of pyrroloquinoline quinone, which is applied in the field of separation and purification of pyrroloquinoline quinone, can solve the problems of complex process and high cost, and achieve the effect of simple process, low cost, and improved purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The buffer used in this embodiment (8%NaCl-1%NH 4 Ac-PH2.0) is prepared according to the following process: water, sodium chloride and ammonium acetate are mixed into a mixed solution, and its pH is adjusted to 2.0 with hydrochloric acid to obtain a buffer solution; wherein, the mass concentration of sodium chloride is 8%, and the acetic acid The mass concentration of ammonium is 1%.

[0035] Get 10 liters of plate and frame filtrate, add 0.05 gram of sodium chloride therein, adjust pH to carry out precipitation 1 hour after being 3.5, filter and remove precipitate, obtain filtrate (about 10.3 liters, be recorded as filtrate after precipitation); After the ultrafiltration membrane ultrafiltration with a molecular weight cut-off of 5000Da, it is concentrated to a volume of 5 liters of concentrate (the content of pyrroloquinoline quinone in the concentrate is about 6 ~ 7 grams);

[0036] Add 15 grams of oxalic acid to the above concentrated solution, adjust the pH to 2....

Embodiment 2

[0043] Get 10 liters of plate and frame filtrate, add 0.05 gram of sodium chloride therein, adjust the pH to 4.0 and carry out precipitation for 1 hour (to separate out the protein), filter to remove the precipitate, and obtain the filtrate (about 10.5 liters, which is recorded as the filtrate after precipitation); This filtrate is after the ultrafiltration membrane ultrafiltration that is 5000Da through molecular weight cut off, is the nanofiltration membrane nanofiltration that is 100-200Da through molecular weight cut off and concentrates to the concentrated solution that volume is 4.22 liters (the content of PQQ in the concentrated solution is about 6- 7 grams);

[0044] Add 8.4 oxalic acid to the concentrated solution to adjust the pH to 2.0, then add 5 liters of n-butanol for extraction to obtain an extract; add 8% NaCl-1% NH to the extract 4 Ac-PH2.0 back extraction 2 times, the addition amount of each buffer solution is 5 liters, obtains back extraction liquid (about 1...

Embodiment 3

[0051] The present embodiment carries out following stripping comparative verification experiment:

[0052] Take 10 liters of plate and frame filtrate, add 0.05 gram of sodium chloride therein, adjust the pH to be 3.5, carry out precipitation for 1 hour, filter and remove the precipitate, obtain filtrate (about 10.3 liters); After membrane ultrafiltration, it is concentrated to a volume of 5.2 liters of concentrated solution (the content of PQQ in the concentrated solution is about 6-7g) through nanofiltration membrane nanofiltration with a molecular weight cut-off of 100-200Da; add 15g oxalic acid in the concentrated solution After adjusting the pH to 2.0, add 5 liters of n-butanol for extraction to obtain an extract;

[0053] Take 4 liters of the above extract, divide it equally into 2 parts, numbered A and B, and carry out test 1 and test 2 respectively:

[0054] Test 1: Buffer used (1% NH 4 AC-PH is 4.0) prepared according to the following process: dissolving ammonium ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com