Antibacterial alginate dressing and preparation method thereof

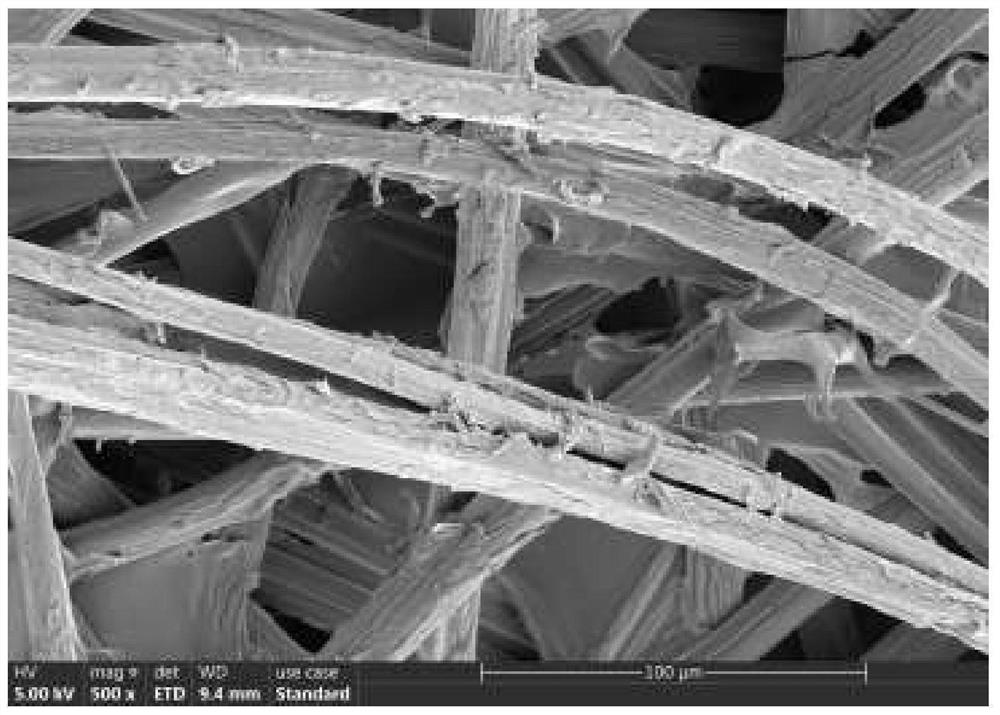

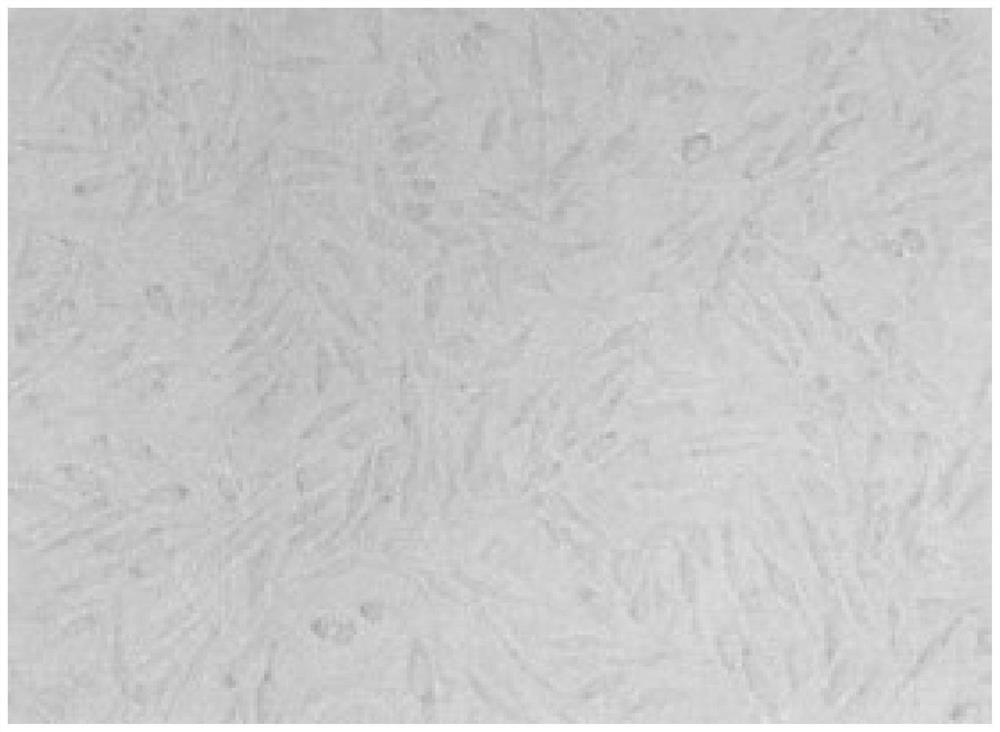

A technology of alginate and antibacterial rate, which is applied in the field of biomedical materials, can solve the problems of difficulty in endowing biological materials with long-lasting antibacterial ability, lack of chemical activity, and weak combination, etc., achieve excellent hemostatic performance, increase microscopic roughness, and promote The effect of wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of aqueous ethanol solution: Weigh 40g of absolute ethanol and 60g of distilled water, and add them to a three-necked bottle.

[0049] 2. Preparation of ethanol aqueous solution of chitosan quaternary ammonium salt: weigh 1 g of chitosan, add it into a three-necked bottle, and stir evenly.

[0050] 3. Weigh 2g of calcium alginate dressing and add it to the plasma treatment apparatus;

[0051] 4. Set the processing power to 60W, pass in argon gas, take it out immediately after processing for 120 seconds, place it in a pre-configured 100 parts by weight of chitosan quaternary ammonium salt ethanol solution, shake it at 37°C for 60 minutes, pour off the reaction liquid.

[0052] 5. Add 200 parts by weight of ethanol solution with a mass fraction of 60%, wash for 60 minutes, and pour off the waste liquid.

[0053] Add 200 parts by weight of absolute ethanol, wash for 30 minutes, pour off the waste liquid, and freeze-dry to obtain the antibacterial calcium a...

Embodiment 2

[0055] 1. Preparation of aqueous ethanol solution: Weigh 60g of absolute ethanol and 40g of distilled water, and add them to a three-necked bottle.

[0056] 2. Preparation of ethanol aqueous solution of chitosan quaternary ammonium salt: weigh 2 g of chitosan, add it into a three-necked bottle, and stir evenly.

[0057] 3. Weigh 2g of sodium alginate dressing and add it to the plasma treatment apparatus;

[0058] 4. Set the processing power to 60W, feed in oxygen, take it out immediately after processing for 120 seconds, place it in the pre-configured 100 parts by weight of chitosan quaternary ammonium salt ethanol solution, shake at 37°C for 60 minutes, and pour out the reaction solution .

[0059] 5. Add 200 parts by weight of ethanol solution with a mass fraction of 60%, wash for 60 minutes, and pour off the waste liquid.

[0060] Add 200 parts by weight of absolute ethanol, wash for 30 minutes, pour off the waste liquid, and freeze-dry to obtain the antibacterial sodium ...

Embodiment 3

[0069] 1. Preparation of aqueous ethanol solution: Weigh 40g of absolute ethanol and 60g of distilled water, and add them to a three-necked bottle.

[0070] 2. Preparation of ethanol aqueous solution of chitosan quaternary ammonium salt: weigh 4 g of chitosan, add it into a three-necked bottle, and stir evenly.

[0071] 3. Weigh 2g of calcium alginate dressing and add it to the plasma treatment apparatus;

[0072] 4. Set the processing power to 90W, feed ammonia gas, take it out immediately after processing for 60 seconds, place it in the pre-configured 100 parts by weight of chitosan quaternary ammonium salt ethanol solution, shake at 37°C for 60 minutes, pour off the reaction liquid.

[0073] 5. Add 200 parts by weight of ethanol solution with a mass fraction of 40%, wash for 60 minutes, and pour off the waste liquid.

[0074] Add 200 parts by weight of absolute ethanol, wash for 30 minutes, pour off the waste liquid, and freeze-dry to obtain the antibacterial alginate dre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com