Method for rapidly preparing multi-element amino acid foliar fertilizer by utilizing crustacean organisms

A crustacean and multi-element technology, which is applied in the direction of animal carcass fertilizer, application, nitrogen fertilizer, etc., can solve the problems of long production cycle of amino acid foliar fertilizer and shorten the production cycle of multi-element amino acid foliar fertilizer, so as to achieve sustainability The effect of production, shortening production cycle, improving speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

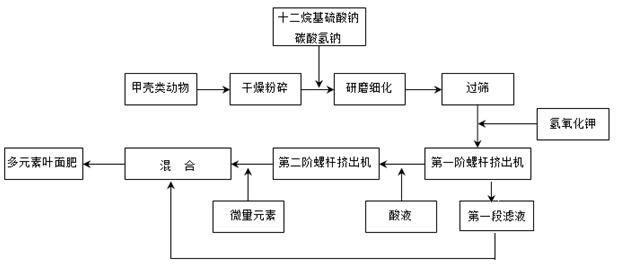

Method used

Image

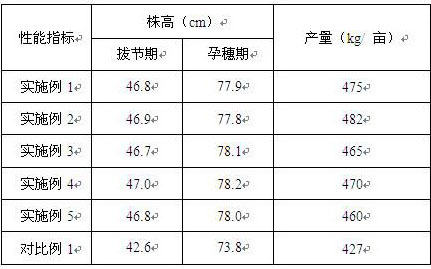

Examples

Embodiment 1

[0037] (1) Dry and pulverize 15kg of stinky shrimp, then add 0.2kg of sodium lauryl sulfate and 0.1kg of sodium bicarbonate, mix well, then add the mixture into a grinder to grind and refine it, and pass through a 400-mesh sieve to obtain materials;

[0038] (2) Add 4 kg of the obtained material into 1 kg of potassium hydroxide solution with a mass concentration of 25%, ultrasonically stir for 3 hours at a temperature of 45°C and an ultrasonic frequency of 40kHz, and then add it to a two-stage screw extruder, pass through the first The shear force of the first-stage screw extruder accelerates the hydrolysis of crustaceans in the lye, followed by pressure filtration and separation to obtain the first-stage filtrate and the first-stage filter residue; the first-stage screw extruder is co-rotating twin-screw extrusion machine;

[0039] (3) Add 3kg of the obtained first-stage filter residue to the second-stage screw extruder and mix with 1kg of nitric acid solution with a mass co...

Embodiment 2

[0042] (1) Dry and pulverize 12kg of dead crabs, then add 0.2kg of sodium lauryl sulfate and 0.2kg of sodium bicarbonate, mix evenly, then add the mixture to a grinder for grinding and refining, and pass through a 400-mesh sieve to obtain materials;

[0043] (2) Add 3.5 kg of the obtained material to 1 kg of potassium hydroxide solution with a mass concentration of 25%, ultrasonically stir for 3.5 hours at a temperature of 42°C and an ultrasonic frequency of 35 kHz, and then add it to a double-stage screw extruder, The shear force of the first-stage screw extruder accelerates the hydrolysis of crustaceans in the lye, and then presses and separates to obtain the first-stage filtrate and the first-stage filter residue; the first-stage screw extruder is a conical screw machine Exit;

[0044] (3) Add 2.5kg of the obtained first-stage filter residue to the second-stage screw extruder and mix with 1.2kg of oxalic acid solution with a mass concentration of 30% for hydrolysis, and th...

Embodiment 3

[0047] (1) Dry and crush 18kg of locusts, then add 0.15kg of sodium lauryl sulfate and 0.1kg of sodium bicarbonate, mix well, then add the mixture to a grinder for grinding and refinement, and pass through a 400-mesh sieve to obtain the material ;

[0048] (2) Add 4.5kg of the obtained material to 1.5kg of potassium hydroxide solution with a mass concentration of 25%, ultrasonically stir for 2.5h at a temperature of 48°C and an ultrasonic frequency of 45kHz, and then add it to a double-stage screw extruder , through the shear force of the first-stage screw extruder to accelerate the hydrolysis of crustaceans in the lye, followed by pressure filtration and separation, to obtain the first-stage filtrate and the first-stage filter residue; the first-stage screw extruder is the same direction double screw extruder;

[0049] (3) Add 3.5kg of the obtained first-stage filter residue to the second-stage screw extruder and mix with 1kg of nitric acid solution with a mass concentration...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap