A kind of preparation method of hexafluoro-1,3-butadiene and its intermediate

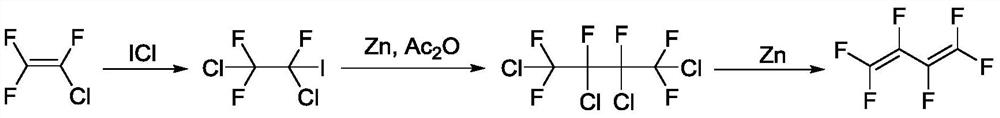

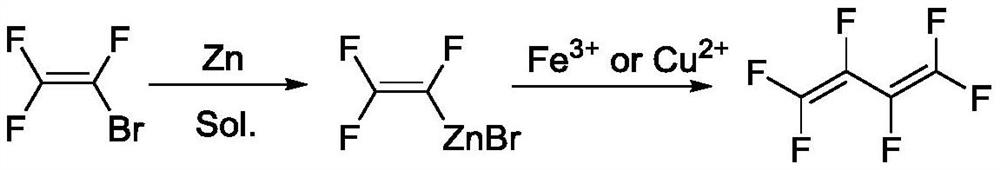

A technology of butadiene and hexafluorobutane, which is applied in the field of synthesizing hexafluoro-1,3-butadiene and its intermediates by telomerization, can solve the problems of high equipment requirements and high process safety risks, and achieve improved The effect of selectivity, simple process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a preparation method of hexafluoro-1,3-butadiene, the preparation method includes intermediate preparation steps and hexafluoro-1,3-butadiene preparation steps, specifically as follows:

[0044] A1. Preparation of 1,4-dibromo-2,3-dichloro-1,1,2,3,4,4-hexafluorobutane

[0045] Add 150g of acetonitrile, 69.1g (0.25mol) of 1,2-dibromo-1-chloro-1,2,2-trifluoroethane, 69.1g (0.25mol) of diphenylmethane peroxide, Acyl 1.8g (7.5mmol), with high-purity N 2 Purge for 10 minutes, then pour 34.8g (0.30mol) of chlorotrifluoroethylene from the steel cylinder into the reactor, heat up to 80°C under mechanical stirring (300-500r / min), the pressure of the reactor rises to about 0.5MPa, and keep warm for 12 hours to end the reaction.

[0046] The reaction solution was analyzed by GC-MS and calculated: the conversion rate of raw material 1,2-dibromo-1-chloro-1,2,2-trifluoroethane was 98.75%, and the conversion rate of intermediate 1,4-dibromo- The selectivity ...

Embodiment 2

[0051] The operation of this embodiment is the same as that of Embodiment 1, the difference is only in:

[0052] During the preparation of the intermediate, the type of initiator was changed, and the dibenzoyl peroxide in Example 1 was replaced with 1.1 g (7.5 mmol) of di-tert-butyl peroxide. The reaction results are shown in Table 1.

[0053] During the preparation of hexafluoro-1,3-butadiene, the type of catalyst was changed, and 2.5 g of zinc iodide was used instead of elemental iodine in Example 1 to obtain 89.20 g of the product. The results are shown in Table 3.

Embodiment 3

[0055] The operation of this embodiment is the same as that of Embodiment 1, the difference is only in:

[0056] During the preparation of the intermediate, the type of initiator was changed, and the dibenzoyl peroxide in Example 1 was replaced with 0.68 g (7.5 mmol) tert-butyl hydroperoxide; the reaction results are shown in Table 1.

[0057] During the preparation of hexafluoro-1,3-butadiene, the type of catalyst was changed, and 1.5 g of 1,2-dibromoethane was used instead of elemental iodine in Example 1 to obtain 95.0 g of the product. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com