A kind of reflective film of high-shielding anti-fingerprint backlight module and its preparation process

A technology of backlight module and preparation process, which is applied in the field of reflective film, which can solve the problems of large light loss and loss, light leakage of reflective film, and damage to metal reflection of metal film, so as to improve density and luminosity, solve the problem of low black purity and poor function Sexually Enhanced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

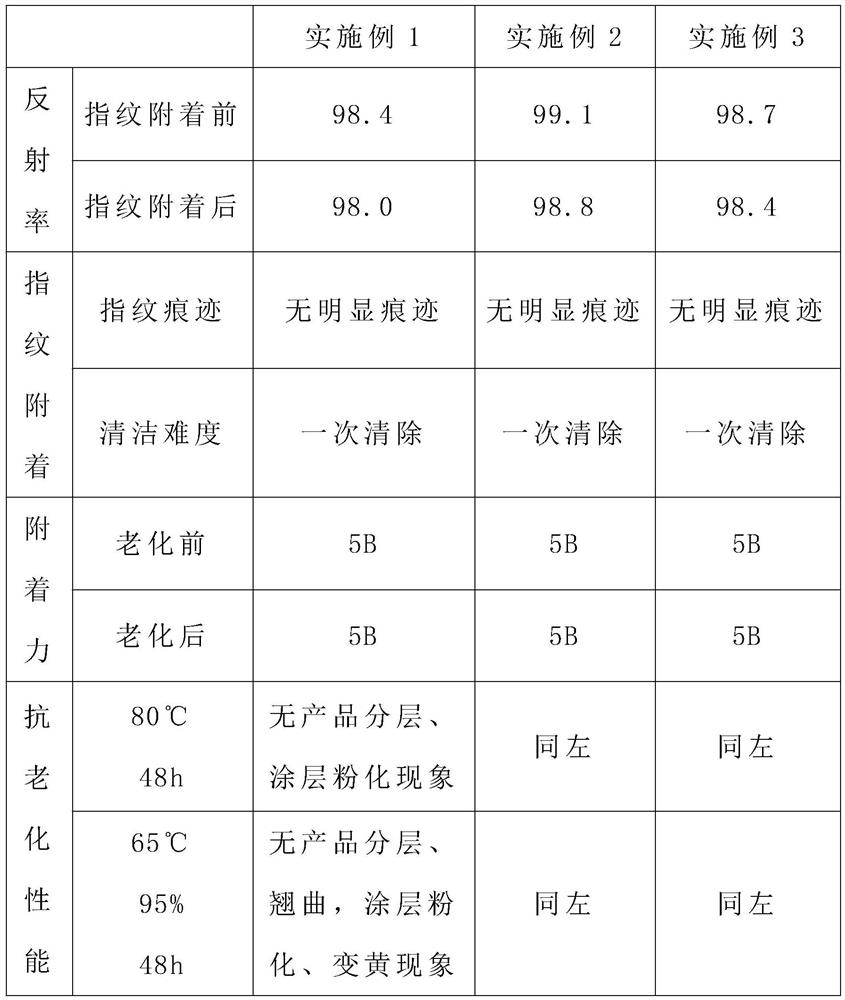

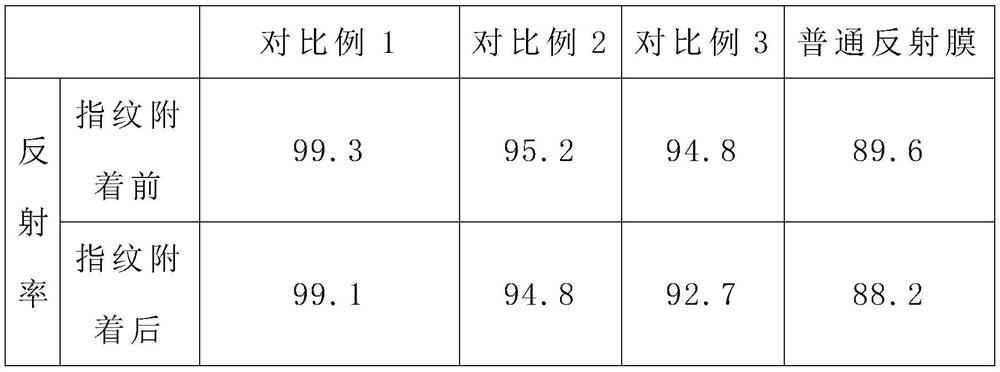

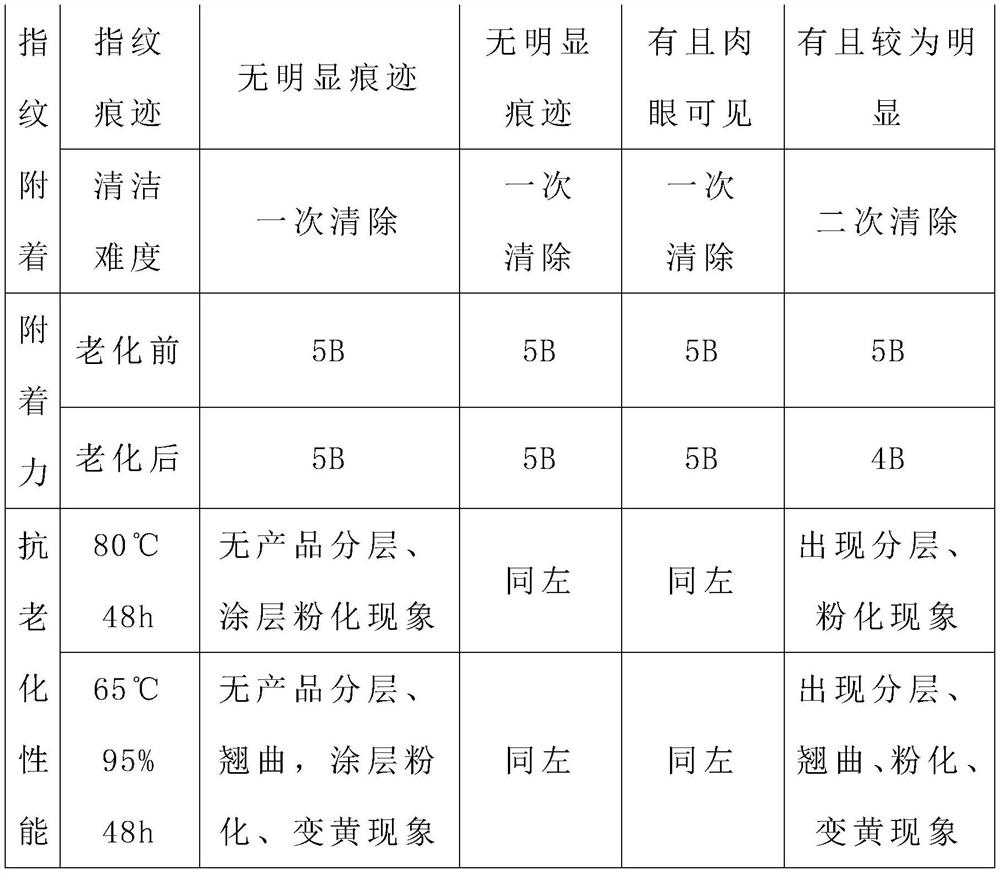

Embodiment 1

[0043] Take 18 parts of water-based resin, add 1 part of wetting agent, 23 parts of soft water and 25 parts of isopropanol, stir at a speed of 450r / min for 25min, then add 23 parts of black color paste, stir at a speed of 1400r / min for 40min, filter The high-refractive coating was obtained afterward; take 28 parts of silane resin, add 3 parts of anti-fingerprint aid, 1 part of adhesion aid, 1 part of substrate wetting agent, 1 part of defoamer, and stir at a speed of 450r / min 10min, add 18 parts of soft water and 24 parts of isopropanol, continue to stir for 25min, then add 23 parts of black color paste, stir at a speed of 1400r / min for 40min, filter to obtain anti-fingerprint paint; wherein the wetting agent is polyoxyethylene Alkyl phenol ether, black color paste is a mixture of polyacrylic acid, cobalt tetroxide, boron carbide, silicon nitride and manganese dioxide, adhesion promoter is aminopropyl methyl diethoxysilane, substrate wetting agent is poly Dimethyl siloxane, de...

Embodiment 2

[0046] Take 20 parts of water-based resin, add 3 parts of wetting agent, 25 parts of soft water and 28 parts of isopropyl alcohol, stir at a speed of 500r / min for 30min, then add 25 parts of black color paste, stir at a speed of 1500r / min for 45min, filter The high-refractive coating was obtained afterward; take 30 parts of silane resin, add 6 parts of anti-fingerprint aid, 2 parts of adhesion aid, 1 part of substrate wetting agent, 1 part of defoamer, and stir at a speed of 500r / min 15min, add 20 parts of soft water and 26 parts of isopropanol, continue to stir for 30min, then add 25 parts of black color paste, stir at a speed of 1500r / min for 45min, and filter to obtain anti-fingerprint paint; wherein the wetting agent is fatty alcohol polymer. Oxyethylene ether, black color paste is a mixture of polyacrylic acid, cobalt tetroxide, boron carbide, silicon nitride and manganese dioxide, adhesion promoter is aminobutylmethyltriethoxysilane, substrate wetting agent is polysiloxan...

Embodiment 3

[0049] Take 22 parts of water-based resin, add 5 parts of wetting agent, 28 parts of soft water and 31 parts of isopropanol, stir at a speed of 550r / min for 35min, then add 28 parts of black color paste, stir at a speed of 1600r / min for 50min, filter A high-refractive coating was then obtained; 33 parts of silane resin were taken, 8 parts of anti-fingerprint aid, 4 parts of adhesion aid, 2 parts of substrate wetting agent, 2 parts of defoamer were added, and stirred at a speed of 550r / min 20min, add 22 parts of soft water and 28 parts of isopropyl alcohol, continue to stir for 35min, then add 28 parts of black color paste, stir at a speed of 1600r / min for 50min, filter to obtain anti-fingerprint paint; wherein the wetting agent is polyoxyethylene Polyoxypropylene block copolymer, black color paste is a mixture of polyacrylic acid, cobalt tetroxide, boron carbide, silicon nitride and manganese dioxide, adhesion promoter is aminopropylmethyldiethoxysilane, substrate wetting The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com