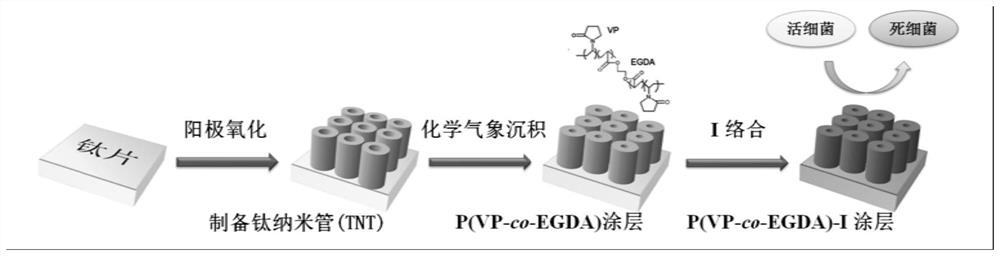

Method and application for preparing titanium nanotube iodine coating by chemical vapor deposition method

A technology of chemical vapor deposition and titanium nanotubes, which is applied in the field of materials, can solve the problems of difficulty in forming uniform coatings, the health hazards of organic solvents, and the inapplicability of substrates sensitive to organic solvents, so as to promote biocompatibility and inhibit resistance. The effect of bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of chemical vapor deposition method of the present invention prepares the method for titanium nanotube iodine coating, comprises the following steps:

[0045] First cut the pure titanium (Ti) sheet into a rectangular sample of a certain size, and polish it with 400#, 800# and 2000# metallographic sandpaper respectively until the surface is smooth without scratches. Rinse the wear debris with deionized water, then ultrasonically clean with acetone to remove the oil on the titanium surface, and finally wash with deionized water, dry it and set it aside.

[0046] Mix 1.26g of ammonium fluoride, 20ml of ultrapure water and 180ml of glycerol to make an electrolyte solution. Add a magnetic stirrer to the electrolyte, place it on a magnetic stirrer and stir at a speed of 500 r / min, and stir for 1 hour to make the electrolyte evenly mixed.

[0047] A constant voltage direct current anodizing method is adopted, the pretreated Ti sheet is used as the anode, and the platin...

Embodiment 2

[0067] A kind of chemical vapor deposition method of the present invention prepares the method for titanium nanotube iodine coating, comprises the following steps:

[0068] First cut the pure titanium (Ti) sheet into a rectangular sample of a certain size, and polish it with 400#, 800# and 2000# metallographic sandpaper respectively until the surface is smooth without scratches. Rinse the wear debris with deionized water, then ultrasonically clean with acetone to remove the oil on the titanium surface, and finally wash with deionized water, dry it and set it aside.

[0069] Mix 1.26g of ammonium fluoride, 20ml of ultrapure water and 180ml of glycerol to make an electrolyte solution. Add a magnetic stirrer to the electrolyte, place it on a magnetic stirrer and stir at a speed of 500 r / min, and stir for 1 hour to make the electrolyte evenly mixed.

[0070] A constant voltage direct current anodizing method is adopted, the pretreated Ti sheet is used as the anode, and the platin...

Embodiment 3

[0075] A kind of chemical vapor deposition method of the present invention prepares the method for titanium nanotube iodine coating, comprises the following steps:

[0076] First cut the pure titanium (Ti) sheet into a rectangular sample of a certain size, and polish it with 400#, 800# and 2000# metallographic sandpaper respectively until the surface is smooth without scratches. Rinse the wear debris with deionized water, then ultrasonically clean with acetone to remove the oil on the titanium surface, and finally wash with deionized water, dry it and set it aside.

[0077] Mix 1.26g of ammonium fluoride, 20ml of ultrapure water and 180ml of glycerol to make an electrolyte solution. Add a magnetic stirrer to the electrolyte, place it on a magnetic stirrer and stir at a speed of 500 r / min, and stir for 1 hour to make the electrolyte evenly mixed.

[0078] A constant voltage direct current anodizing method is adopted, the pretreated Ti sheet is used as the anode, and the platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com