Pinhole-free large-area controllable growth perovskite film forming process

A large-area, perovskite technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of uncontrollable evaporation and reaction rates of organic and inorganic sources, rough surface of thin films, cavity The body is easy to cause pollution and other problems, and achieves the effect of controllable large-area dense film-forming technology without pinholes, improving film quality and avoiding shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

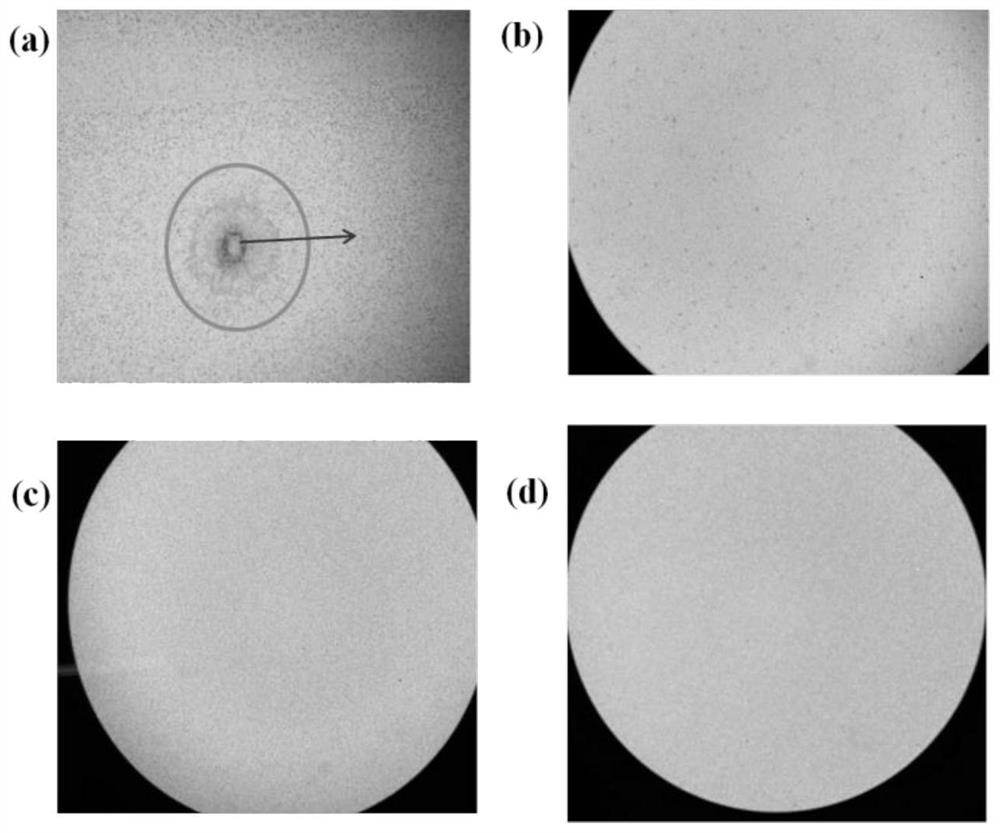

Image

Examples

Embodiment 1

[0040] According to the ratio of N:Sn=0.02:1, weigh 9.57mg of hexadecyldimethylbenzyl ammonium chloride raw material and dissolve it in 13mL of deionized water, filter it for 30min after ultrasonication, and then use a pipette Pipette 80 μL of liquid and drop it vertically on the ETL layer SnO 2 Above, rotate at 4000rpm / 30s after the liquid is spread, anneal at 100°C for 10min after rotation, and the film thickness of the obtained low surface energy material substrate is about 20nm.

[0041] Place the low surface energy material substrate sample obtained above in a thermal evaporation, the sample is installed in the middle of the turntable, the turntable speed is set to 1krpm / min, and about 1.30g of PbI is placed in the cavity 2 Powder, in a vacuum of 4*10 -6 torr pressure, for Pb I 2 The film is pre-steamed, the thermal evaporation power supply voltage is adjusted to 0.82V, the current is 125A, the pre-steaming rate is controlled to 0.05nm / s, and it is reset to zero after t...

Embodiment 2

[0044] According to the ratio of N:Sn=0.04:1, weigh 19.14mg of hexadecyldimethylbenzyl ammonium chloride raw material, dissolve it in 3mL deionized water, filter it after ultrasonic for 30min, and then use a pipette Pipette 80 μL of liquid and drop it vertically on the ETL layer SnO 2 Above, rotate at 4000rpm / 30s after the liquid is spread, anneal at 100°C for 10min after rotation, and the film thickness of the obtained low surface energy material substrate is about 20nm. Place the low surface energy material substrate sample obtained above in a thermal evaporation, the sample is installed in the middle of the turntable, the turntable speed is set to 1krpm / min, and about 1.30g of PbI is placed in the cavity 2 Powder, in a vacuum of 4*10 - 6 torr pressure, for PbI 2 The film is pre-steamed, the thermal evaporation power supply voltage is adjusted to 0.82V, the current is 125A, the pre-steaming rate is controlled to 0.05nm / s, and it is reset to zero after the pre-steaming rea...

Embodiment 3

[0047] 2 mg of 4,4'-((methyl(4-sulfonyl)amino)bis(propane-3,1-diyl))bis(dimethyl-ammoniumdiyl)bis-(butane-1- Sulfonate) (MSAPBS) was dissolved in 1 mL of MeOH and AcOH with a volume ratio of 0.97:0.03, sonicated for 30 min and then filtered for use. Then pipette 80 μL of liquid and drop it vertically on the ETL layer SnO 2 Above, after the liquid is spread, the spin coating speed is 4000rpm / 30s, the annealing temperature is set at 100°C and the annealing time is 10min, and the film thickness of the low surface energy amphoteric small molecule material substrate is 8-9nm.

[0048] Place the substrate sample obtained above in a thermal evaporation, the sample is installed in the middle of the turntable, the turntable speed is set at 1krpm / min, and about 1.30g of PbI is placed in the cavity 2 Powder, thermal evaporation power supply voltage adjusted to 0.82V, current to 125A, in a vacuum of 4*10 -6 torr pressure, for PbI 2 The film is pre-steamed, the pre-steaming rate is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com