Polyether ether ketone bone repair material with antibacterial properties and preparation method of polyether ether ketone bone repair material

A kind of polyetheretherketone, repair material technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the polyetheretherketone bone repair material with antibacterial properties specifically includes the following steps:

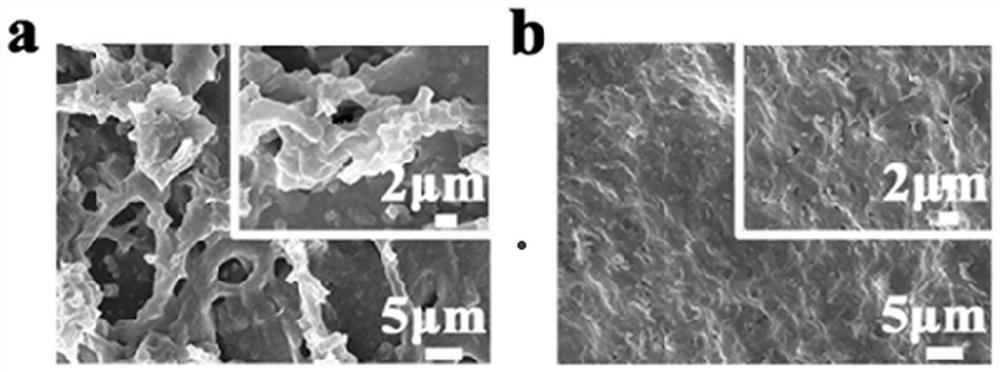

[0037] Step 1: Ti 3 C 2 Preparation

[0038] First, add 1g of LiF (lithium fluoride) to 20mL of 9mol / L hydrochloric acid solution and stir evenly, and then add 1g of Ti to the LiF / HCl solution 3 AlC 2 A mixture was obtained, and the mixture was stirred and reacted in an ice bath for 30 minutes and at a temperature of 35° C. for 24 hours, and then washed with deionized water to obtain Ti. 3 C 2 Tx suspension, will obtain Ti 3 C 2 Centrifuge the Tx suspension and wash it to a pH of 6 to obtain multilayer Ti 3 C 2 Tx. Ti to be obtained 3 C 2 Tx is re-dispersed in deionized water to obtain Ti 3 C 2 The dispersion liquid of Tx, then the dispersion liquid is placed in an ice bath and sonicated for 1 hour, and then the dispersion liquid after the ultrasonic treatment is centrifuged and the supernatant liquid is removed to obtain a monolay...

Embodiment 2

[0048] The polyether ether ketone bone repair material with antibacterial properties was prepared according to the preparation method described in Example 1, except that:

[0049] In the step 1, the concentration of hydrochloric acid is 10mol / L, the mixture is stirred at 35°C for 48h, and the reaction time is 48h. 3 C 2 The Tx suspension is centrifuged and washed to a pH value of 5-6.

[0050] In the step 2, add N to the reaction solution 2 H 4 ·H 2 O, H 2 PtCl·6H 2 The amount of O is 650 μL and 300 μL, respectively.

[0051] In the step 3, Ti 3 C 2 The molar concentration ratio of the suspension and the CoNWs suspension is 1:0.75, and the ultrasonic time of the mixed solution is 30 min.

[0052] In the step 4, the ultrasonic time of the polyetheretherketone substrate (PEEK) in concentrated sulfuric acid is 15 minutes.

[0053] In the step 5, the drying temperature of SPEEK after immersion is 55° C., and the number of cycles of immersion and drying is 4.

Embodiment 3

[0055] The polyether ether ketone bone repair material with antibacterial properties was prepared according to the preparation method described in Example 1, except that:

[0056] In the step 1, the concentration of hydrochloric acid is 9.5 mol / L, the mixture is stirred at 35°C for a reaction time of 36 hours, and Ti 3 C 2 The Tx suspension was centrifuged and washed to a pH of 5.5.

[0057] In the step 2, NaOH adjusts the pH value of the raw material liquid to 13, and adds N to the reaction liquid 2 H 4 ·H 2 O, H 2 PtCl·6H 2 The amount of O is 620 μL and 240 μL, respectively.

[0058] In the step 3, Ti 3 C 2 The molar concentration ratio of the suspension and the CoNWs suspension is 1:1.

[0059] In the step 4, the ultrasonic time of the polyetheretherketone substrate (PEEK) in concentrated sulfuric acid is 15 minutes.

[0060] In the step 5, the drying temperature of SPEEK after dripping is 50° C., and the number of repeated dripping and drying cycles is 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com