A high-salinity heavy metal refractory shale gas extraction wastewater treatment system and treatment method

A shale gas exploitation and treatment method technology is applied in the field of high salinity heavy metal refractory shale gas exploitation wastewater treatment system, and can solve the problems of high operating cost of the treatment process, inability to utilize intermediate products as resources, and poor system stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

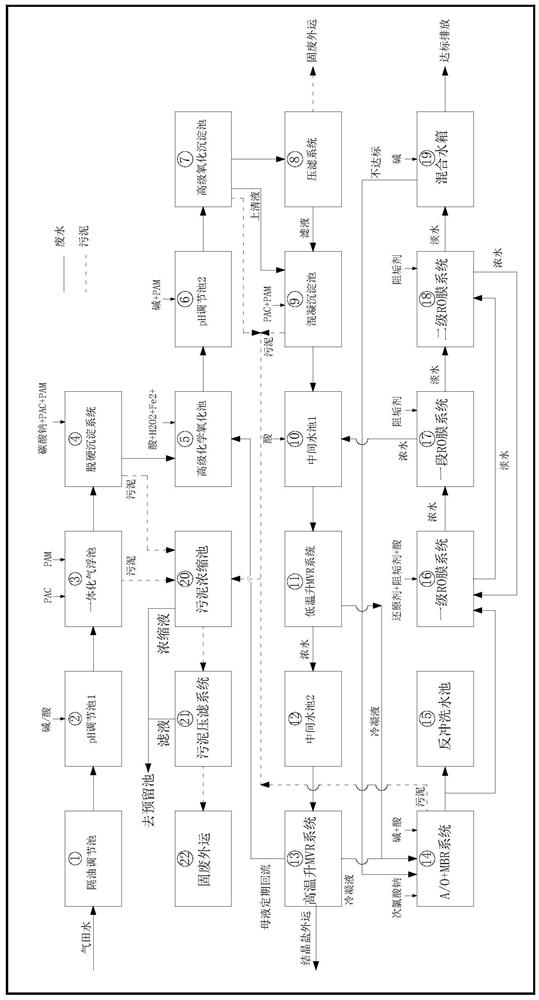

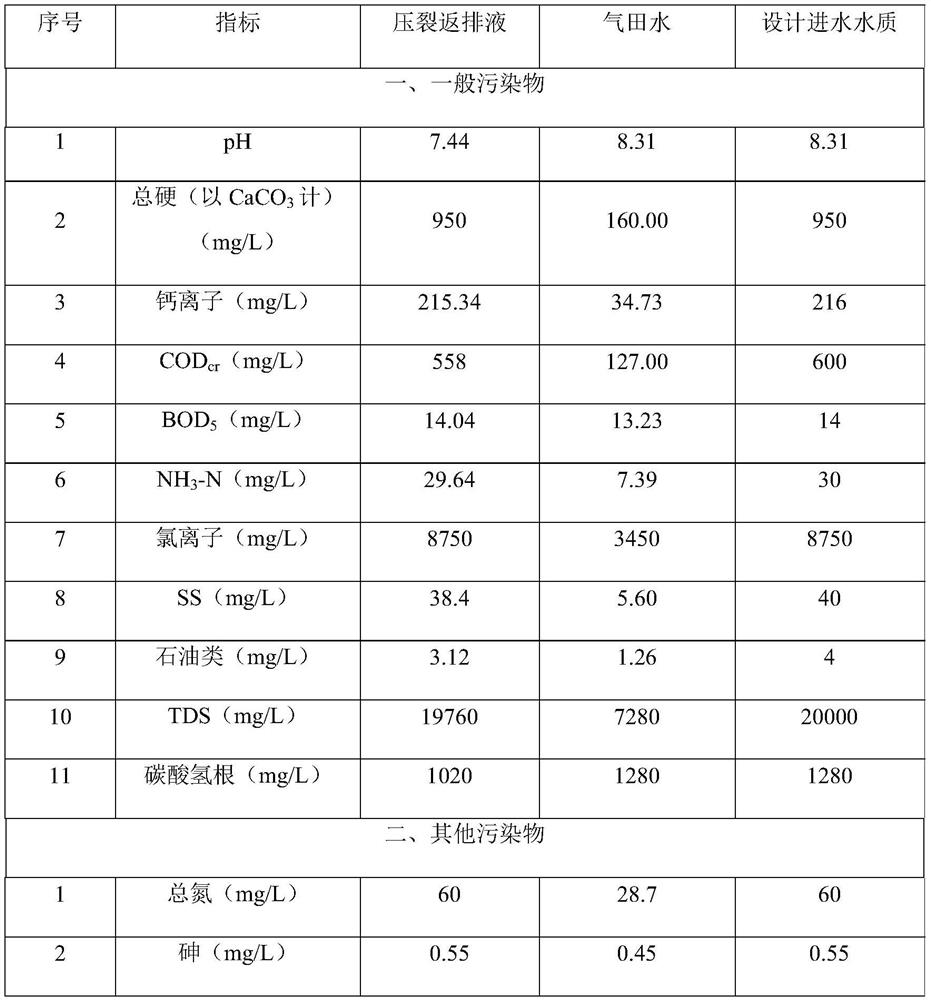

[0064] A system for treating high-salinity heavy metal refractory shale gas exploitation wastewater, including a pretreatment unit, an MVR evaporation unit, an advanced treatment unit and a membrane treatment unit that are connected in sequence; a coagulation sedimentation tank and a low temperature rise MVR system There is an intermediate pool 1 in between.

[0065] Among them, the pretreatment unit includes an oil separation adjustment tank, a pH adjustment tank 1, an integrated air flotation tank, a dehardening sedimentation tank, an advanced chemical oxidation tank, a pH adjustment tank 2, an advanced chemical oxidation sedimentation tank, and a coagulation sedimentation tank. The wastewater is treated with oil separation, adjustment, pH adjustment, air flotation, de-hardening, advanced oxidation, etc., to remove oily substances, micro-suspended solids, colloidal substances and hardness in the wastewater, and oxidatively degrade the organic matter in the wastewater. The su...

Embodiment 2

[0074] A method for treating high-salinity heavy metal refractory shale gas exploitation wastewater, comprising the following steps:

[0075] (1) Preprocessing unit

[0076] S1. Oil separation adjustment tank: The gas field water enters the oil separation adjustment tank from outside the plant area, and the oil in the waste water is treated by the oil suction machine set in the oil separation tank. The waste water after oil removal enters the adjustment tank, and the wastewater is treated The mass is uniform and the waste liquid is formed;

[0077] S2, pH adjustment tank 1: use the metering pump to add sodium hydroxide to adjust the pH of the waste liquid 2, after adjusting the pH value of the waste water to 9, the waste liquid 2 with a large number of fine suspended particles will be formed;

[0078] S3. Integrated air flotation tank: use metering pump to add PAC and PAM, remove the tiny suspended substances and colloids in waste liquid 2 by air flotation, and form waste liq...

Embodiment 3

[0095] A method for treating high-salinity heavy metal refractory shale gas exploitation wastewater, comprising the following steps:

[0096] (1) Preprocessing unit

[0097] S1. Oil separation adjustment tank: The gas field water enters the oil separation adjustment tank from outside the plant area, and the oil in the waste water is treated by the oil suction machine set in the oil separation tank. The waste water after oil removal enters the adjustment tank, and the wastewater is treated The mass is uniform and the waste liquid is formed;

[0098] S2, pH adjustment tank 1: use a metering pump to add sodium hydroxide to adjust the pH of the waste liquid II, and adjust the pH value of the waste water to 8 to 9 to form a large number of fine suspended particles of the waste liquid II;

[0099] S3. Integrated air flotation tank: use metering pump to add PAC and PAM, remove the tiny suspended substances and colloids in waste liquid 2 by air flotation, and form waste liquid 3 in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com