Manufacturing method of lithium ion battery negative electrode structure and lithium ion battery negative electrode structure

A lithium-ion battery and manufacturing method technology, applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve the problems of large surface of nano-materials, difficult to filter and wash, affecting battery performance, etc., and achieve good crystallinity and high production efficiency. , to ensure the effect of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

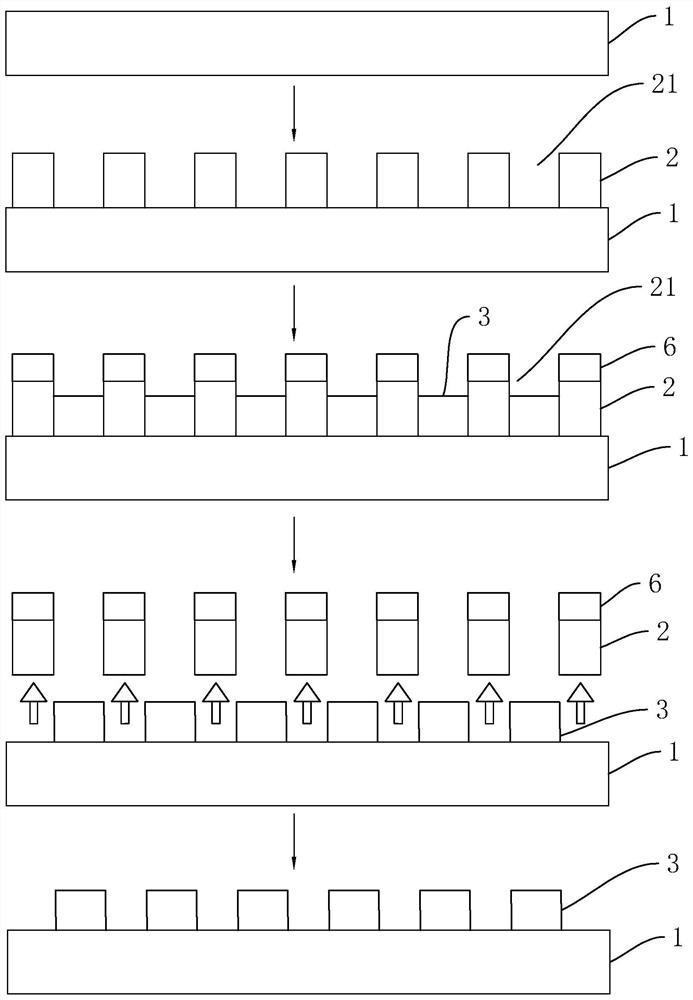

[0058] A kind of manufacturing method of lithium-ion battery negative electrode structure, such as figure 1 shown, including the following steps:

[0059] Provide a collector plate 1;

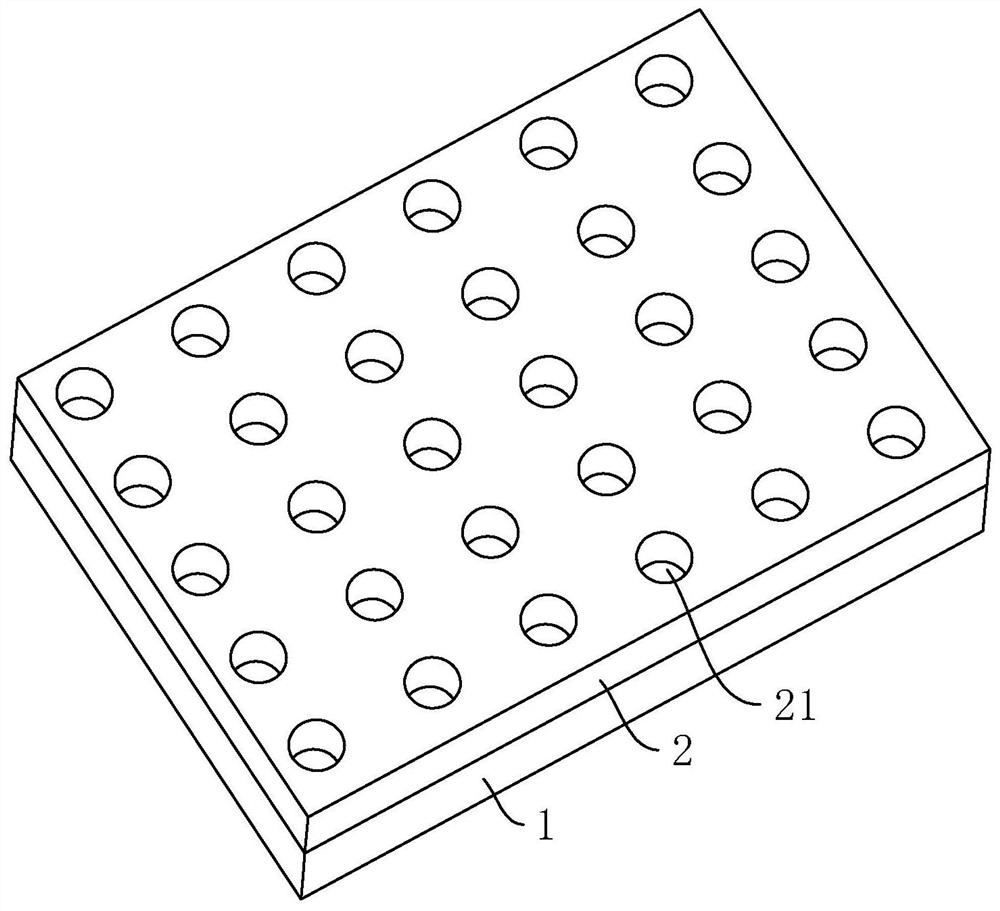

[0060] Attach a porous nano-template 2 on the current collector plate 1;

[0061] Forming a plurality of nano-array columns 3 in the holes 21 of the porous nano-template 2 by means of pulsed laser deposition;

[0062] The porous nano-template 2 is removed, and the nano-array pillars 3 are fixed on the current collector plate 1 in a protruding array to obtain a lithium-ion battery negative electrode structure.

[0063] The lithium-ion battery negative electrode structure prepared by the present invention includes a current collector plate 1 and a plurality of nano-array columns 3 protrudingly arrayed and fixed on the current collector plate 1, wherein the diameter of the nano-array columns 3 is between 90-300nm, and the nano-array The height of the columns 3 is between 50-400nm, and the spaci...

Embodiment 2

[0069] A method for manufacturing a lithium-ion battery negative electrode structure, comprising the steps of: figure 1 As shown, a current collector plate 1 is provided; the current collector plate 1 is copper foil.

[0070] Attach a porous nano-template 2 on the current collector plate 1;

[0071] A plurality of nano-array columns 3 are formed in the holes 21 of the porous nano-template 2 by means of pulsed laser deposition; the nano-array columns 3 are Fe 3 o 4 Nano-array column 3; the copper foil is heated to 300-500° C. before pulsed laser deposition, the laser energy is 250-350 mJ, and the laser frequency is 5-10 Hz.

[0072] The porous nano-template 2 is removed, and the nano-array column 3 is fixed on the current collector plate 1 in a protruding array, wherein the diameter of the nano-array column 3 is between 90-300nm, and the height of the nano-array column 3 is between 50-400nm, The distance between nano-array pillars 3 is 65-125nm.

[0073] Fe 3 o 4 The nano...

Embodiment 3

[0076] A kind of manufacturing method of lithium-ion battery negative electrode structure, such as figure 1 shown, including the following steps:

[0077] (1) Cut the metal foil and clean and pre-treat it;

[0078] (2) Soak the PMMA / AAO template in an organic solvent to separate the PMMA support layer, and then attach it to the cleaned and pretreated metal foil to prepare the metal foil attached to the AAO template;

[0079] (3) On the metal foil bonded with the AAO template obtained in the above step (2), a highly ordered Fe 3 o 4 Nanoarray;

[0080] (4) For the Fe prepared in the above step (3) 3 o 4 The nano-array sample is cooled, and then the AAO template is glued off.

[0081] Wherein the organic solvent preferably uses acetone.

[0082] Preferably in this embodiment, the metal foil is copper foil, and step (1) specifically includes the following steps:

[0083] a. Soak the Cu foil in acetone and ultrasonically clean it for 5-20 minutes;

[0084] b. Then immerse t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com