Preparation method and application of special adhesive mortar material for foam glass external thermal insulation system

A technology for bonding mortar and thermal insulation system, applied in thermal insulation, climate change adaptation, building components, etc., can solve the problems of lack of high elasticity, shedding, substandard, etc. The effect of the compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, a special bonded mortar material for foam glass external thermal insulation system is prepared by using the following proportioning raw materials:

[0049] P.O4.25 cement 34kg;

[0050] Fly ash 4kg;

[0051] Silica fume 2kg;

[0052] Medium sand 60kg;

[0053] Redispersible latex powder 2.5kg;

[0054] Hydroxypropyl methylcellulose 0.18kg;

[0055] Polypropylene fiber 0.2kg;

[0056] Defoamer 0.1kg;

[0057] Water reducer 0.1kg.

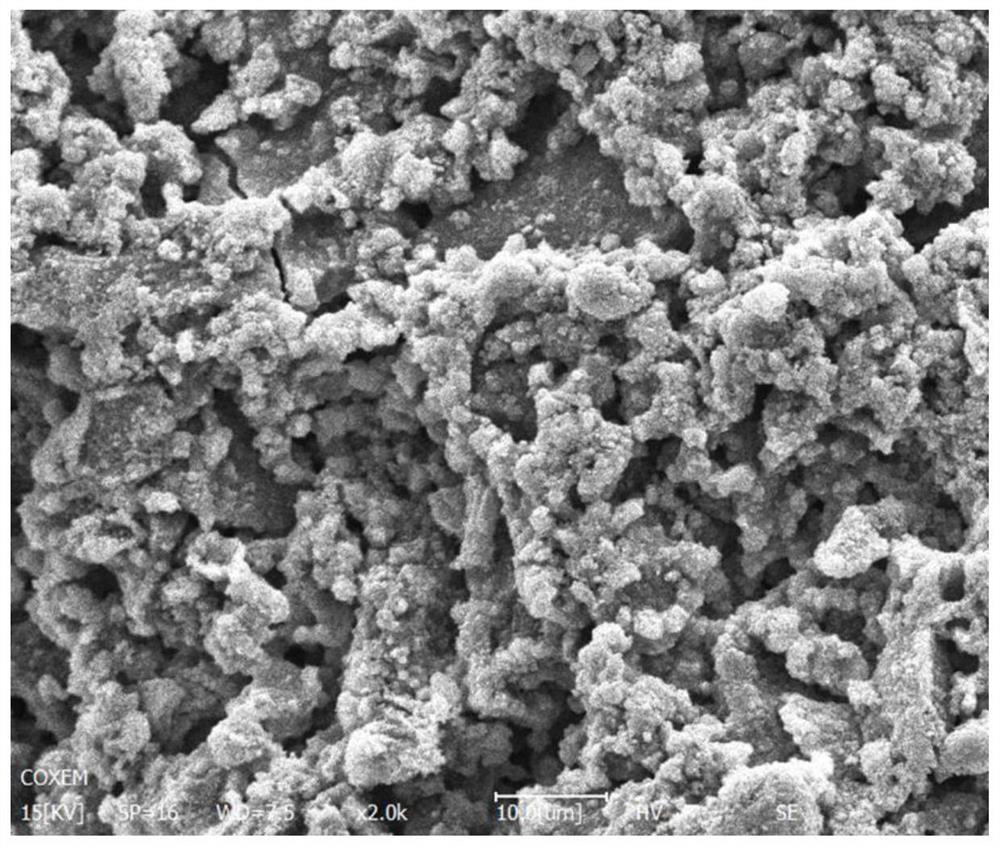

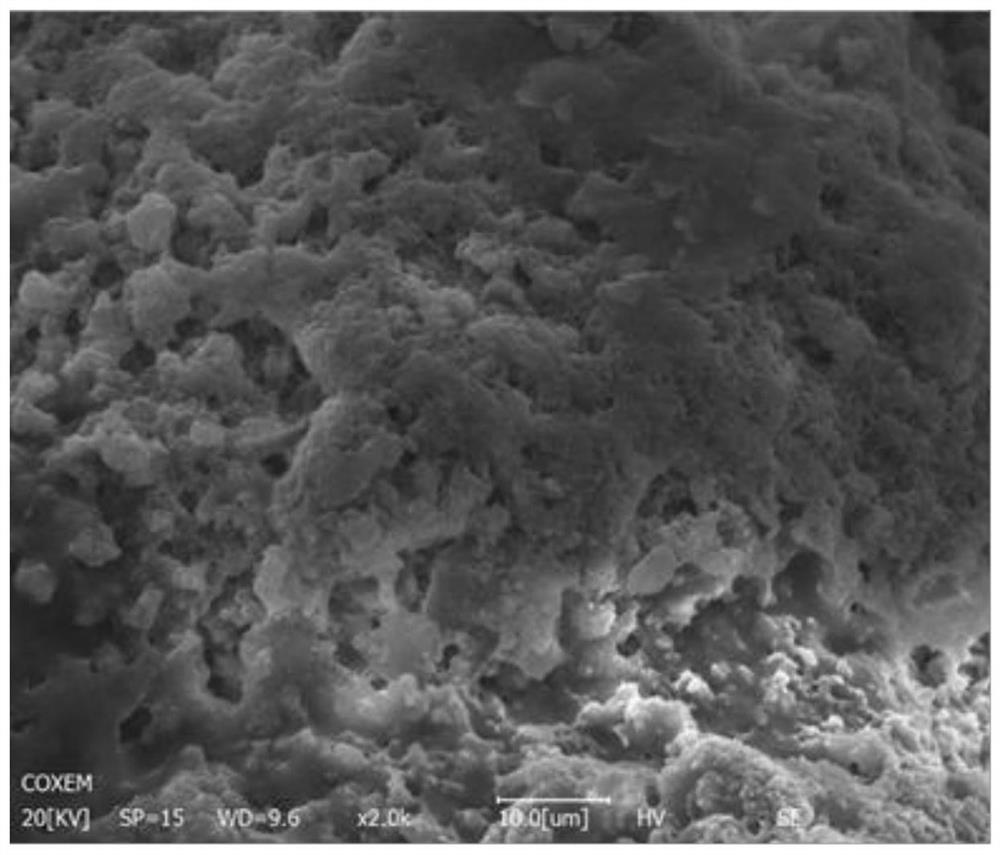

[0058] In this embodiment, P.O4.25 cement is Yangchun Shanshui brand, which is the main cementitious material of the bonded mortar. Fly ash is a secondary fly ash which has a pozzolanic activity which will contribute more to the mortar than alkali consumption. The average particle size of silica fume is 0.1-0.3 microns, and it has a large specific surface area, which plays a positive role in the water retention performance of mortar.

[0059]The dispersible latex powder is water-redispersible vinyl acetate / ethylene...

Embodiment 2

[0078] This embodiment is basically the same as Embodiment 1, especially in that:

[0079] In this embodiment, a preparation method of special adhesive mortar for foam glass external thermal insulation system adopts the following preparation steps:

[0080] (1) Take raw material according to the quality of raw material in the embodiment, weighing accuracy ± 0.5%;

[0081] (2) Add the weighed cement, sand, fly ash and silica fume into the mixer, the amount of stirring is 30% to 70% of the capacity of the mixer, mix and stir for 5 minutes, and the stirring rate is 120r / min;

[0082] (3) Add hydroxypropyl methylcellulose ether, redispersible latex powder, polypropylene fiber, water reducer, defoamer, and then continue to stir for 10 minutes at a stirring rate of 120r / min;

[0083] (4) The stirred material is sealed and waterproofed.

[0084] The adhesive mortar prepared in this example should be mixed with water at the construction site. The amount of water used for mixing shou...

Embodiment 3

[0087] In this embodiment, a special bonded mortar material for foam glass external thermal insulation system is prepared by using the following proportioning raw materials:

[0088] P.O4.25 cement 34kg;

[0089] Fly ash 4kg;

[0090] Silica fume 2kg;

[0091] Medium sand 60kg;

[0092] Redispersible latex powder 2.5kg;

[0093] Hydroxypropyl methylcellulose 0.06kg;

[0094] Polypropylene fiber 0.25kg;

[0095] Defoamer 0.1kg;

[0096] Water reducer 0.1kg;.

[0097] In this embodiment, P.O4.25 cement is Yangchun Shanshui brand, which is the main cementitious material of the bonded mortar. Fly ash is a secondary fly ash which has a pozzolanic activity which will contribute more to the mortar than alkali consumption. The average particle size of silica fume is 0.1-0.3 microns, and it has a large specific surface area, which plays a positive role in the water retention performance of mortar.

[0098] The dispersible latex powder is water-redispersible vinyl acetate / ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com