HfO2/HfB2 composite ceramic coating with high infrared emissivity and preparation method of HfO2/HfB2 composite ceramic coating

A technology of infrared emissivity and ceramic coating, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of limited compound application, complicated preparation process, expensive price, etc. Good capacitance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Provide a HfO 2 / HfB 2 The preparation method of composite high infrared emissivity ceramic coating comprises the following steps:

[0034] 1) With 92wt% HfO 2 Powder and 8wt% B 4 C powder is the raw material, adding deionized water and binder polyvinyl alcohol to mix and grind to obtain a uniform slurry, wherein the binder is the raw material HfO 2 and B 4 3% of C mass, the volume ratio of deionized water and mixed raw materials is 1.2:1;

[0035]2) The powder with high sphericity is obtained by spray granulation method. During spray granulation, the temperature of the drying tower is 200°C, and the rotation speed of the material pump is 3000r / min; the particle size is 45-75μm by standard sieve screening. HfO 2 / B 4 C composite agglomerated powder;

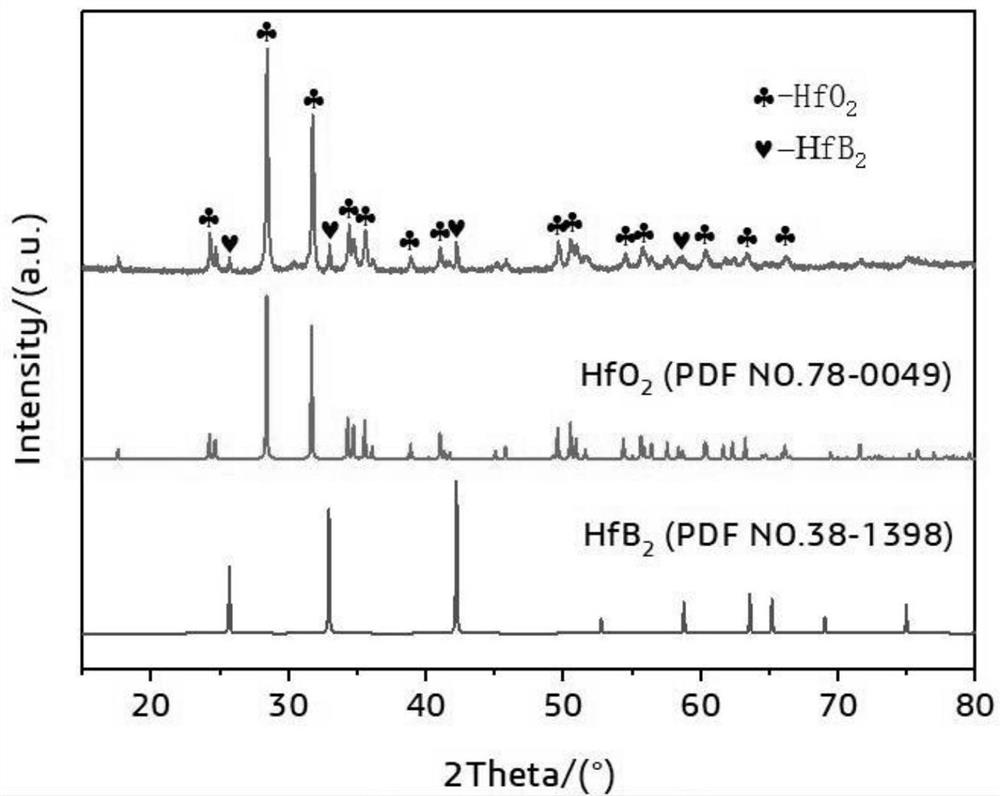

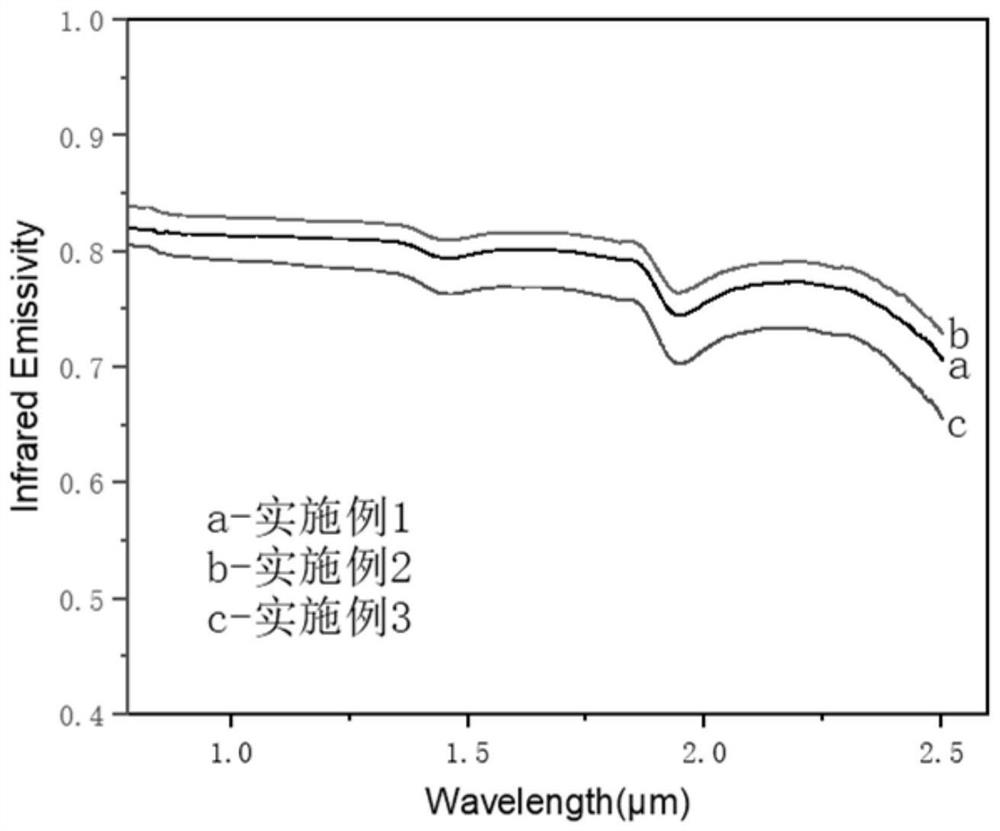

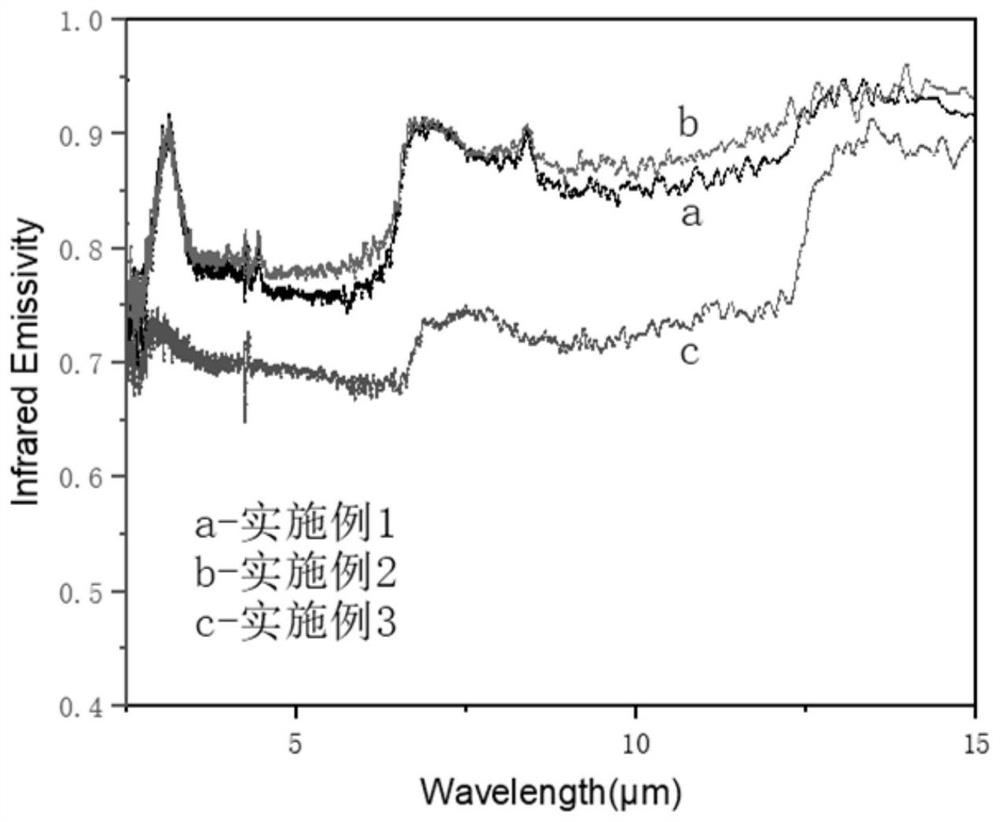

[0036] 3) HfO was sprayed by plasma spraying 2 / B 4 C composite agglomerated powder was sprayed onto a preheated stainless steel substrate to obtain HfO 2 / HfB 2 Composite high-infrared emissivity ceramic coati...

Embodiment 2

[0040] Provide a HfO 2 / HfB 2 The preparation method of composite high infrared emissivity ceramic coating comprises the following steps:

[0041] 1) With 95wt% HfO 2 powder and 5wt% B 4 C powder is used as raw material, adding deionized water and self-made binder to mix and grind to obtain a uniform slurry, wherein the binder is raw material HfO 2 and B 4 3% of C mass, the volume ratio of deionized water and mixed raw materials is 1.5:1;

[0042] 2) Use the spray granulation method to obtain powder with high sphericity. During spray granulation, the temperature of the drying tower is 200°C, and the speed of the material pump is 2500r / min; the particle size is 45-75μm by standard sieve screening. HfO 2 / B 4 C composite agglomerated powder;

[0043] 3) HfO was sprayed by plasma spraying 2 / B 4 C composite agglomerated powder was sprayed onto a preheated stainless steel substrate to obtain HfO 2 / HfB 2 Composite high infrared emissivity ceramic coating, where the spr...

Embodiment 3

[0046] Provide a HfO 2 / HfB 2 The preparation method of composite high infrared emissivity ceramic coating comprises the following steps:

[0047] 1) With 98wt% HfO 2 powder and 2wt% B 4 C powder is used as raw material, adding deionized water and self-made binder to mix and grind to obtain a uniform slurry, wherein the binder is raw material HfO 2 and B 4 3% of C mass, the volume ratio of deionized water and mixed raw materials is 1.3:1;

[0048] 2) Use the spray granulation method to obtain powder with high sphericity. When spray granulation, the temperature of the drying tower is 180°C, and the rotation speed of the material pump is 3500r / min; the particle size is 45-75μm through standard sieve screening. HfO 2 / B 4 C composite agglomerated powder;

[0049] 3) HfO was sprayed by plasma spraying 2 / B 4 C composite agglomerated powder was sprayed onto a preheated stainless steel substrate to obtain HfO 2 / HfB 2 Composite high-infrared emissivity ceramic coating, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com