High-strength and high-antibacterial absorbable suture line

A kind of suture, high-strength technology, applied in the direction of conjugated synthetic polymer artificial filament, conjugated artificial filament, fiber chemical characteristics, etc., can solve the limitation of the use range of polyglycolic acid absorbable suture, incision redness, swelling, leakage Liquid and other problems, to achieve the effect of enhanced force, good biocompatibility, and firm knot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

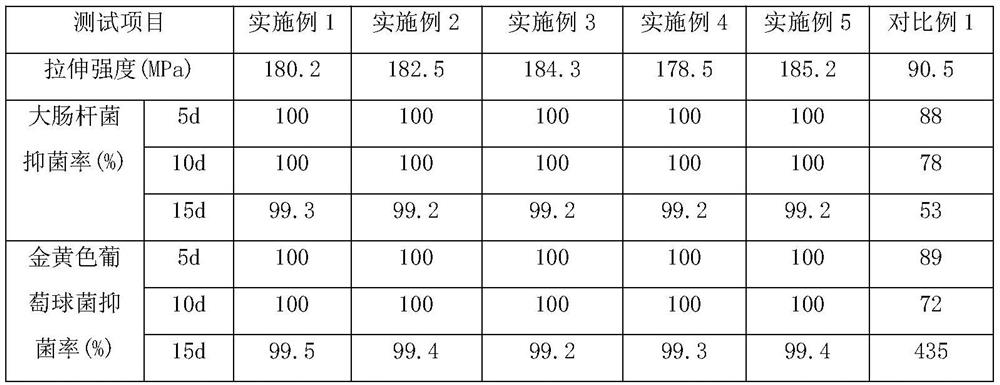

Examples

Embodiment 1

[0026] A high-strength and highly antibacterial absorbable suture is composed of the following components by mass: 90 parts of polyglycolic acid nanomaterials, 20 parts of chitosan, 4 parts of polyethylene glycol, 2.5 parts of cinnamon oil, and 2.5 parts of mannitol Wherein, the preparation method of polyglycolic acid nanomaterials is: (1) graphene oxide, polyethylene glycol and organic solvent are mixed homogeneously and ultrasonically dispersed to obtain graphene oxide dispersion liquid A, wherein graphene oxide kind is single-layer graphene oxide , the type of polyethylene glycol is polyethylene glycol 400, the organic solvent is acetone, the weight ratio of graphene oxide, polyethylene glycol and organic solvent is 0.02:2:50, the ultrasonic frequency is 49KHz, and the ultrasonic time is 3h; (2 ) adding the mixed solution A to the acetone solution of chloroacetic acid and stirring evenly to obtain the mixed solution B; (3) adding the acetone solution of triethylamine dropwis...

Embodiment 2

[0031] A high-strength and high-antibacterial absorbable suture is composed of the following components by mass: 80 parts of polyglycolic acid nanomaterials, 25 parts of chitosan, 3.5 parts of polyethylene glycol, 2 parts of cinnamon oil, and 2 parts of mannitol Wherein, the preparation method of polyglycolic acid nanomaterials is: (1) graphene oxide, polyethylene glycol and organic solvent are uniformly mixed and ultrasonically dispersed to obtain graphene oxide dispersion A, wherein the graphene oxide type is double-layer graphene oxide , the type of polyethylene glycol is polyethylene glycol 600, the organic solvent is methyl ethyl ketone, the weight ratio of graphene oxide, polyethylene glycol and organic solvent is 0.05:5:100, the ultrasonic frequency is 98KHz, and the ultrasonic time is 1.5h; ( 2) Add the mixed solution A to the methyl ethyl ketone solution of chloroacetic acid and stir evenly to obtain the mixed solution B; (3) Add the methyl ethyl ketone solution of tri...

Embodiment 3

[0036]A high-strength and highly antibacterial absorbable suture is composed of the following components by mass: 85 parts of polyglycolic acid nanomaterials, 25 parts of chitosan, 3.5 parts of polyethylene glycol, 2 parts of cinnamon oil, and 3 parts of mannitol Wherein, the preparation method of polyglycolic acid nanomaterials is: (1) graphene oxide, polyethylene glycol and organic solvent are mixed homogeneously and ultrasonically dispersed to obtain graphene oxide dispersion liquid A, wherein graphene oxide kind is three-layer graphene oxide , the type of polyethylene glycol is polyethylene glycol 1000, the organic solvent is acetonitrile, the weight ratio of graphene oxide, polyethylene glycol and organic solvent is 0.025:2.5:75, the ultrasonic frequency is 30KHz, and the ultrasonic time is 2.5h; ( 2) Add the mixed solution A to the methyl ethyl ketone solution of chloroacetic acid and stir evenly to obtain the mixed solution B; (3) Add the acetone solution of triethylamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com