High-dispersion composite modified heavy calcium carbonate and preparation method thereof

A heavy calcium carbonate, composite modification technology, applied in the treatment of dyeing high molecular organic compounds, chemical instruments and methods, dyeing low molecular organic compounds and other directions, can solve problems such as single modification effect, reduce production costs, Enhance the effect of modification and have broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

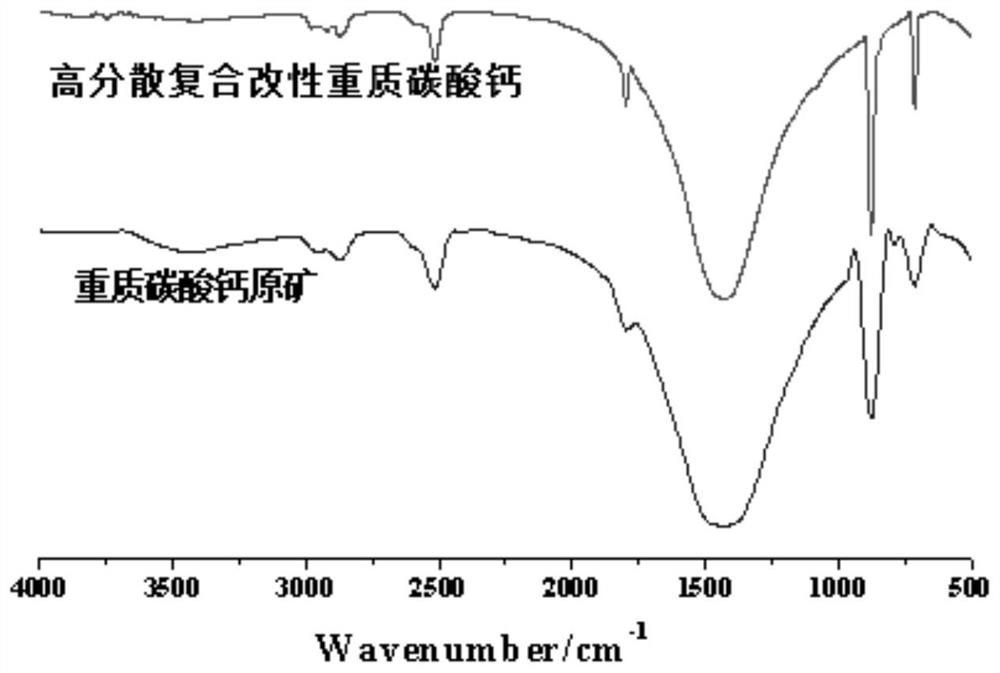

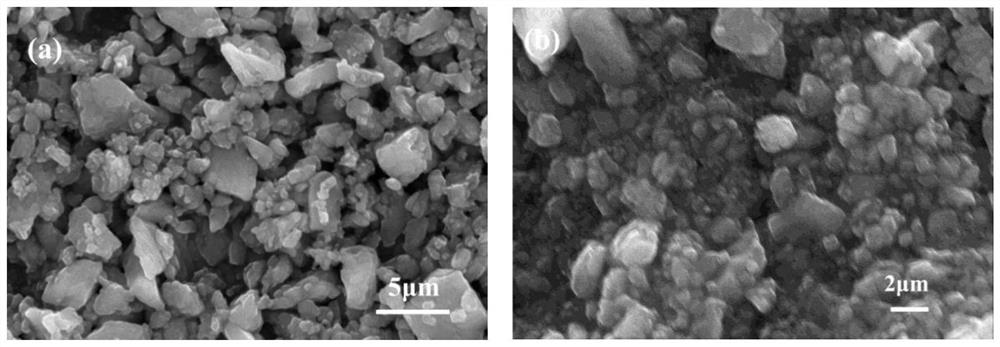

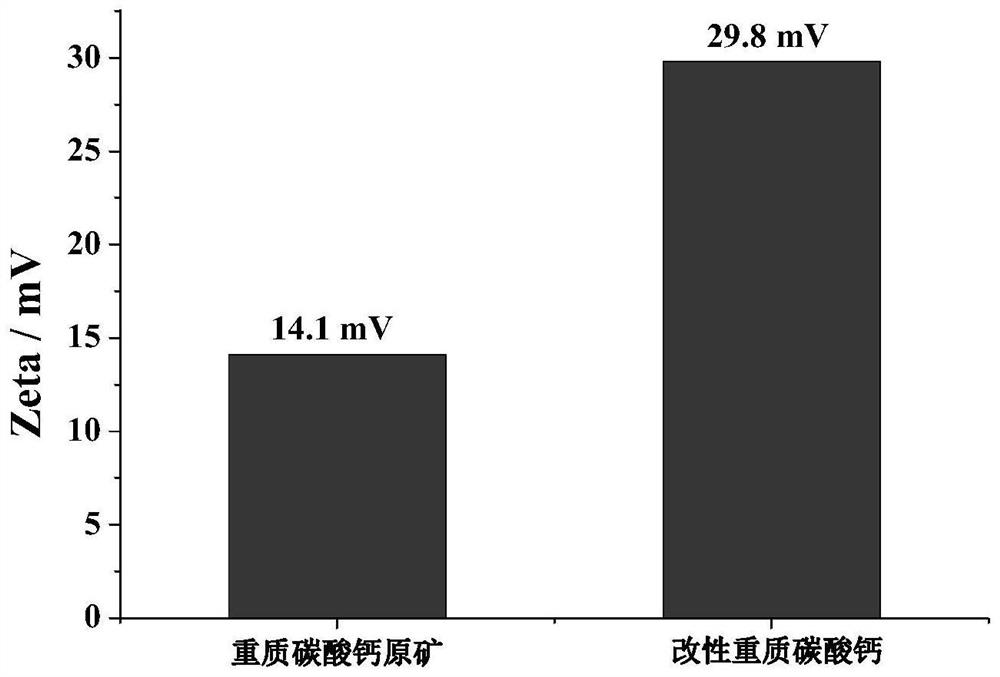

[0044] The high-dispersion composite modified ground calcium carbonate provided in this example is prepared by using heavy calcium carbonate raw ore produced in Xianfeng County, and using polymethyl methacrylate emulsion as a modifier.

[0045] The above-mentioned highly dispersed composite modified ground calcium carbonate of the present embodiment is obtained by the following method, and the steps are as follows:

[0046](1) Add 0.5 g of polyvinyl alcohol powder into 100 mL of water, heat to 65° C. to completely dissolve the polyvinyl alcohol, and obtain an aqueous solution of polyvinyl alcohol with a concentration of 0.5% by mass; Add emulsifier sodium lauryl sulfate (its consumption is 8% of the mass of methyl methacrylate monomer) and methyl methacrylate monomer 45mL successively, the gained mixture is heated up to 80 ℃, under stirring condition again to Add 1.5 mL of ammonium persulfate solution with a concentration of 1 mol / L to the reaction system dropwise. After the d...

Embodiment 2

[0056] The high-dispersion composite modified ground calcium carbonate provided in this example is prepared from heavy calcium carbonate raw ore produced in Xianfeng County, using polymethyl methacrylate emulsion and stearic acid as modifiers.

[0057] The above-mentioned highly dispersed composite modified ground calcium carbonate of the present embodiment is obtained by the following method, and the steps are as follows:

[0058] (1) Add 0.3g of polyvinyl alcohol powder into 100mL of water, heat to 70°C to completely dissolve the polyvinyl alcohol, and obtain an aqueous solution of polyvinyl alcohol with a concentration of 0.3% by mass; Add emulsifier sodium lauryl sulfate (its consumption is 8% of the mass of methyl methacrylate monomer) and methyl methacrylate monomer 42mL successively, the gained mixture is heated up to 80 ℃, under stirring condition again to 1.5 mL of 1 mol / L ammonium persulfate solution was added dropwise to the reaction system. After the dropwise addit...

Embodiment 3

[0066] The high-dispersion composite modified ground calcium carbonate provided in this example adopts heavy calcium carbonate produced in Xianfeng County, and uses polymethyl methacrylate emulsion and titanate as modifiers.

[0067] The above-mentioned highly dispersed composite modified ground calcium carbonate of the present embodiment is obtained by the following method, and the steps are as follows:

[0068] (1) Add 0.3g of polyvinyl alcohol powder into 100mL of water, heat to 60°C to completely dissolve the polyvinyl alcohol, and obtain an aqueous solution of polyvinyl alcohol with a concentration of 0.3% by mass; then add it to the aqueous solution of polyvinyl alcohol Add emulsifier sodium lauryl sulfate (its consumption is 8% of the mass of methyl methacrylate monomer) and methyl methacrylate monomer 45mL successively, the gained mixture is heated up to 80 ℃, under stirring condition again to 2.5 mL of 1 mol / L ammonium persulfate solution was added dropwise to the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com