Double cross-linked integrated seamless composite hydrogel scaffold for articular cartilage repair

A composite hydrogel and hydrogel technology, applied in prosthetics, coatings, medical science, etc., can solve problems such as delamination of the osteocartilage interface, cell death, and the inability to realize the preparation of loaded cells, so as to improve the interface binding force , to avoid the effect of excessive calcification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

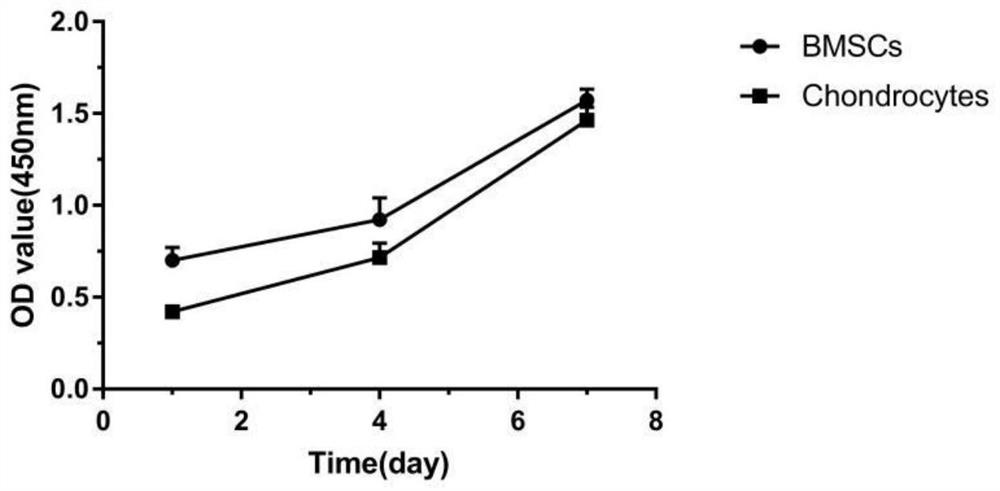

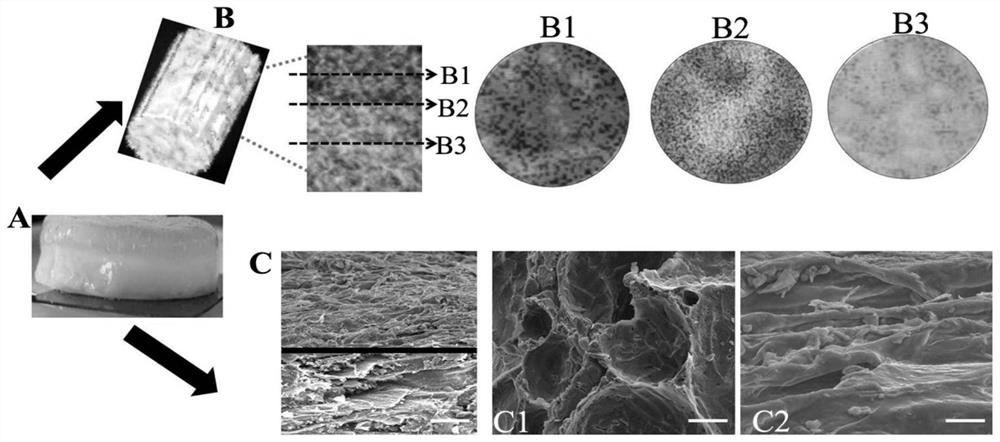

[0044] The preparation of double-crosslinked integrated seamless composite hydrogel scaffold includes the following steps:

[0045] (1) The sodium alginate molecule is reacted with 3-(p-benzylamino)-1,2,4,5-tetrazine (BAT) containing an azide group, so that the hydroxyl group of sodium alginate is grafted with azide Group (-N=N-), the grafting rate is 120% as characterized by nuclear magnetic mass spectrometry.

[0046] (2) Preparation of the subchondral bone layer: the final concentration of sodium alginate prepared in step (1) is 40g / L, and the bioceramic particles are evenly dispersed in the solution, and the content of the bioceramic particles in the solution is 1-100mg / L mL, aseptically defoamed, and stored at low temperature for future use.

[0047] Spread the mixed liquid into a thin film with a thickness of 3 mm, and prepare an ion-crosslinked hydrogel film through a calcium ion solution, that is, a subchondral bone layer hydrogel scaffold is prepared.

[0048] (3) P...

Embodiment 2

[0060] The preparation of double-crosslinked integrated seamless composite hydrogel scaffold includes the following steps:

[0061] (1) Grafting 3-(p-benzylamino)-1,2,4,5-tetrazine (BAT) containing azide group on the hydroxyl group of sodium alginate molecule, grafting the hydroxyl group of sodium alginate Azide group (-N=N-), NMR mass spectrometry shows that the grafting rate is 120%.

[0062] (2) Preparation of subchondral bone layer: preparation of mixed liquor, wherein the final concentration of sodium alginate containing step (1) prepared is 40g / L; the final concentration of collagen is 8g / L; and the bioceramic particles are uniformly dispersed in The above mixed solution is aseptically defoamed and stored at low temperature for future use.

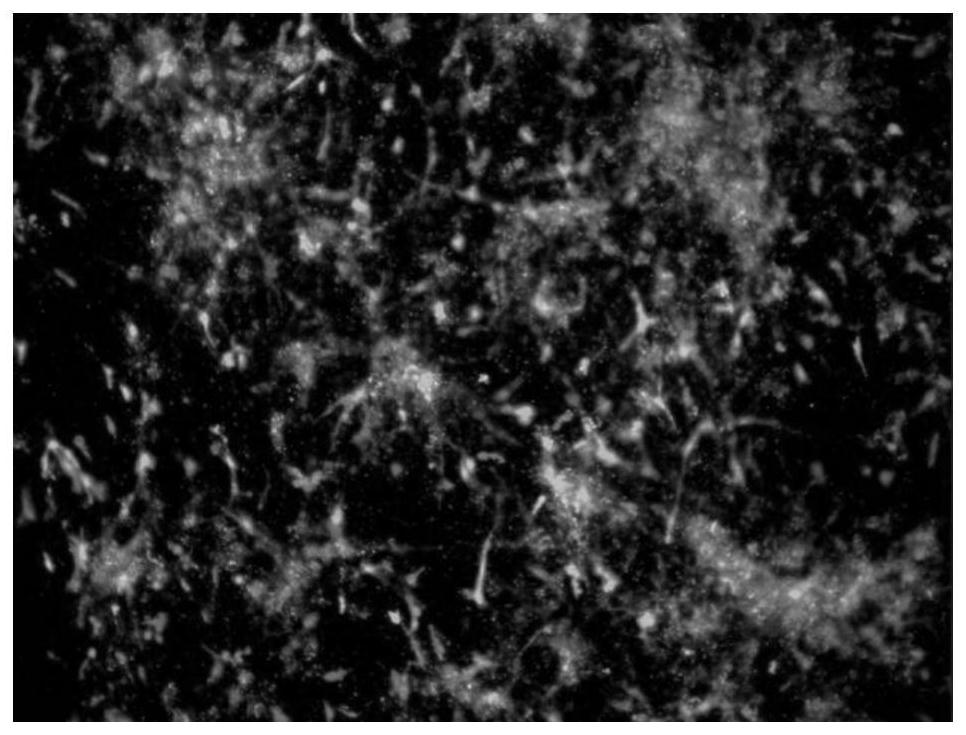

[0063] Add mesenchymal stem cells to the above mixed solution at a cell density of 1×10 7 / mL;

[0064] The above mixed solution was spread into a thin film with a thickness of 3 mm, and an ion-crosslinked hydrogel film was prepar...

Embodiment 3

[0073] The preparation of double-crosslinked integrated seamless composite hydrogel scaffold includes the following steps:

[0074] (1) The carboxyl group of sodium alginate molecule is grafted with furfuryl amine containing furyl radicals, and the carboxyl group in sodium alginate and the amino-NH in furfuryl amine are used to 2 Amidation reaction occurs, and sodium alginate molecules are grafted with furan groups (C 4 h 4 (0), the grafting rate of furan radicals characterized by nuclear magnetic mass spectrometry is 75%.

[0075] (2) Preparation of subchondral bone layer: preparation of mixed liquor, wherein the final concentration of sodium alginate containing step (1) prepared is 40g / L; the final concentration of collagen is 8g / L; and the bioceramic particles are uniformly dispersed in The above mixed solution is aseptically defoamed and stored at low temperature for future use.

[0076] Add mesenchymal stem cells to the above mixture, and the cell density is 10 6 cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com