Fluorosilicone rubber compound and preparation method thereof

A technology of mixed rubber and fluorosilicone raw rubber, which is applied in the field of rubber, can solve the problems affecting the application range of fluorosilicone mixed rubber, reduce the tear strength, and single function, achieve good durability and chemical resistance, and improve Tear strength and hardness, effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides a method for preparing the fluorosilicone compound described in the above technical solution, comprising:

[0044] Fluorosilicone raw rubber, hydroxyl fluorosilicone oil, polyvinyl fluorosilicone oil, and fluorine-containing structural control agent modified white carbon black are heated and kneaded, then mixed with a vulcanizing agent, and kneaded to obtain a fluorosilicone compound rubber.

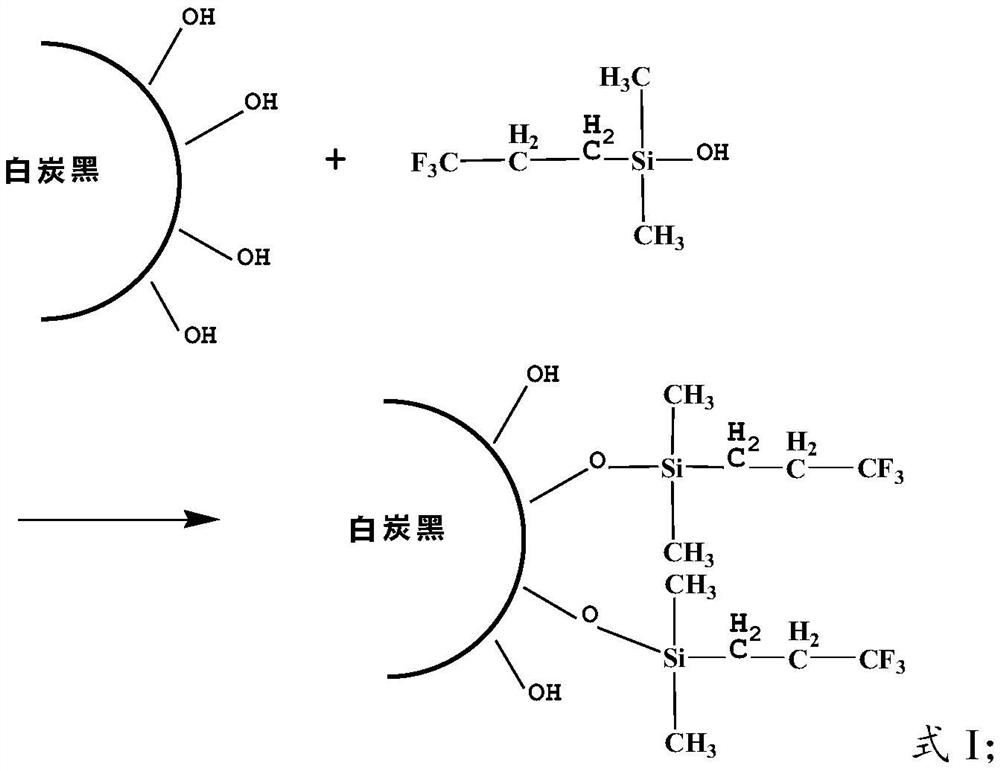

[0045] The preparation method of the fluorine-containing structural control agent modified white carbon black of the present invention is specifically:

[0046] The white carbon black and the fluorine-containing structural control agent are mixed, the temperature is raised and stirred, the low boilers are removed in a vacuum, the temperature is continued to be raised, and the drying is performed to obtain the fluorine-containing structured control agent modified white carbon black.

[0047] First add white carbon black, then add fluorine-containing s...

Embodiment 1

[0054] Example 1 Preparation of Fluorine-Containing Structural Control Agent Modified Silica

[0055] Add 1000 g of hydrophilic white carbon black XHG-150 into the reaction kettle, then add 20 g of trimethyl-tris(trifluoropropyl)cyclotrisilazane, and stir and react at 70° C. for 4 hours. Remove low boilers in a vacuum, grind, dry, then raise the temperature to 180°C, keep warm for 2 hours and discharge to obtain refined fluorine-containing structuring control agent modified white carbon black for future use.

Embodiment 2

[0056] Example 2 Preparation of Fluorine-Containing Structural Control Agent Modified Silica

[0057] Add 1000g of hydrophilic white carbon black XHG-200 into the reaction kettle, then add 80g of trifluoropropylsilanol, and stir and react at 70°C for 4 hours. Remove low boilers in a vacuum, grind, dry, then raise the temperature to 180°C, keep warm for 2 hours and discharge to obtain refined fluorine-containing structuring control agent modified white carbon black for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com