Monatomic algae removal and sterilization pool coating and preparation method thereof

An algae killing fungicide, atomic technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of non-recyclability, pollution, high toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0039]The preparation of single-atom antibacterial disinfectant, step 1, the aqueous solution of 5g / L silver nitrate is added in the diatomite, wherein the mass ratio of transition metal salt and carrier is 1:20, the ultrasonic 30min dispersion is uniform under the condition of 100kHz of gained solution, Then the mixed solution was stirred at 100r / min for 12h;

[0040] Step 2, warming up the mixed solution obtained in step 1 to the boiling point of water, volatilizing at high temperature, evaporating the solvent, and fully grinding for 0.5 hours with a ball mill at a speed of 50 r / min to obtain a solid powder;

[0041] In step 3, the solid powder obtained in step 2 was heat-treated in an air atmosphere at 400° C. for 2 hours, cooled to room temperature, and ground by a ball mill at a speed of 50 r / min for 20 minutes to obtain the desired catalyst.

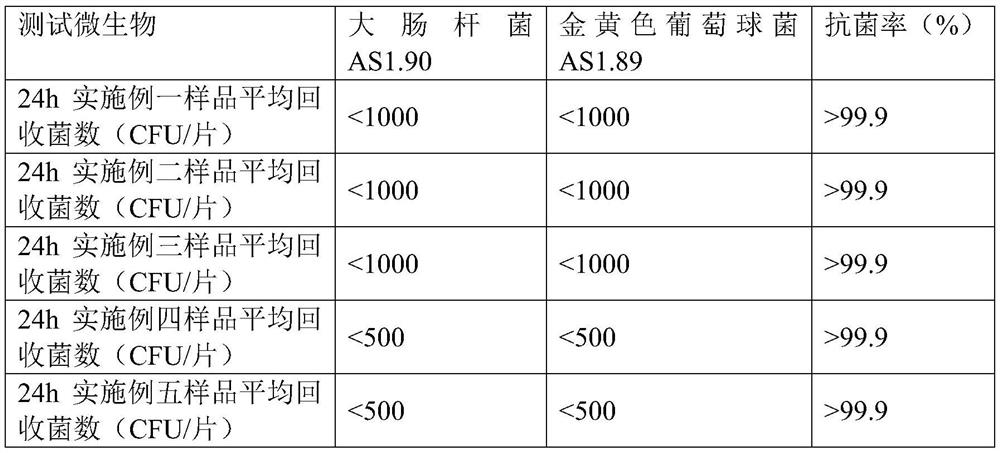

Embodiment 1

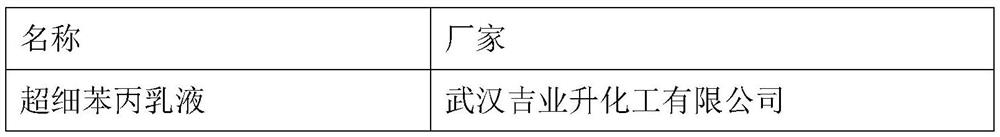

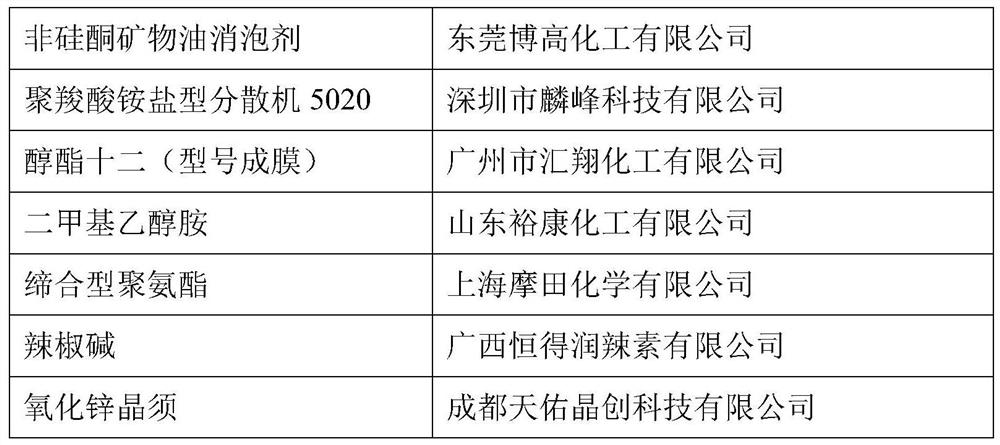

[0044] A single-atomic algae-killing and sterilizing pool coating, comprising the following components in weight percent: 23.5% deionized water, 2.5% polycarboxylate ammonium salt, 0.5% non-silicone mineral oil, 1.8% propylene glycol, 23% filler, olefin 1.5% polyurethane, 2% alcohol ester twelve, 40% ultra-fine styrene-acrylic emulsion, 0.2% dimethylethanolamine, 5% single-atom algicide; the filler is made of titanium dioxide, 3 % kaolin, 2% precipitated aluminum silicate composition.

[0045] A preparation method for single-atom algicidal and bactericidal pool coatings, comprising the following steps:

[0046] 1) In the selection of stainless steel Tietong, first add 14.5kg of deionized water, stirring at a speed of 300 rpm, under continuous stirring, add 2.5kg of polycarboxylate ammonium salt, 0.2kg of non-silicone mineral oil defoamer, 1.8kg propylene glycol, stir for 5 minutes to make all materials evenly mixed;

[0047] 2) Adjust the stirring speed to 500 rpm, slowly ad...

Embodiment 2

[0050] The difference between Example 2 and Example 1 is: 25.5% of deionized water, 42% of ultra-fine styrene-acrylic emulsion, 1% of single-atom algicide and bactericide in the single-atom algicidal and bactericidal pool coating formula, and other components are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com