Multi-metal surface protective agent and preparation method and application thereof

A surface protective agent and multi-metal technology, applied in the field of water circulation system, can solve the problem of high requirements for circulating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

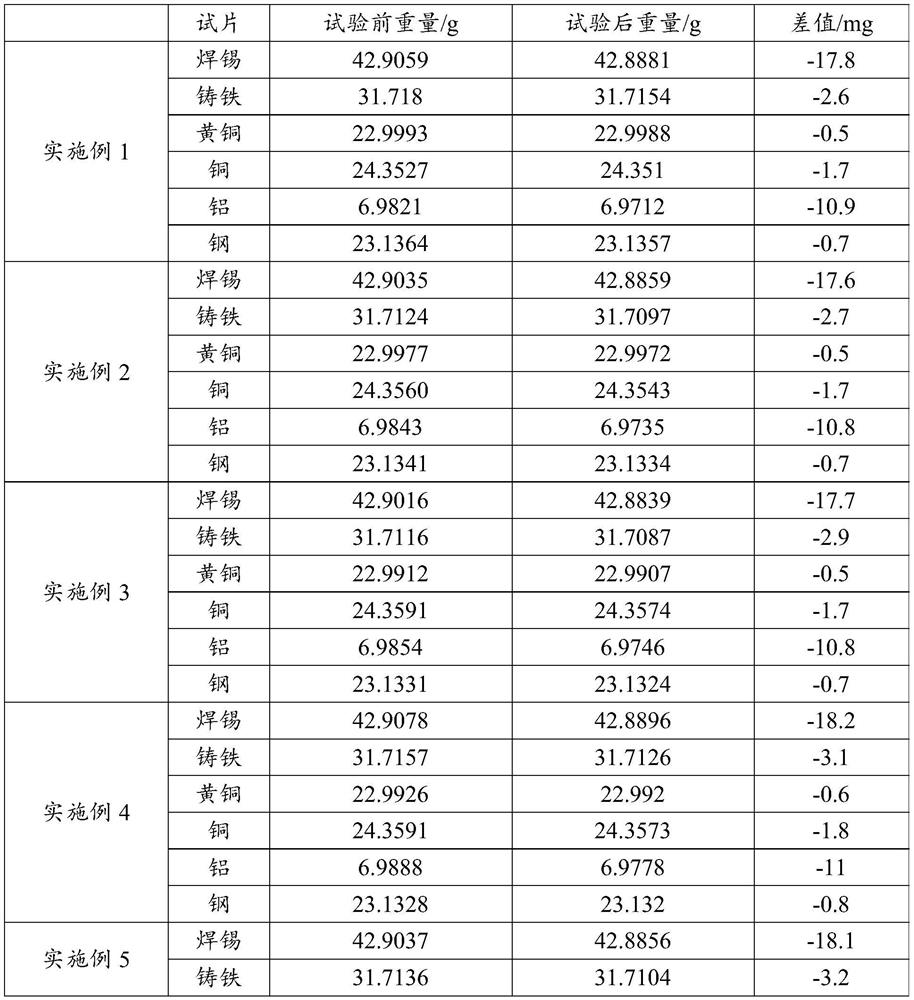

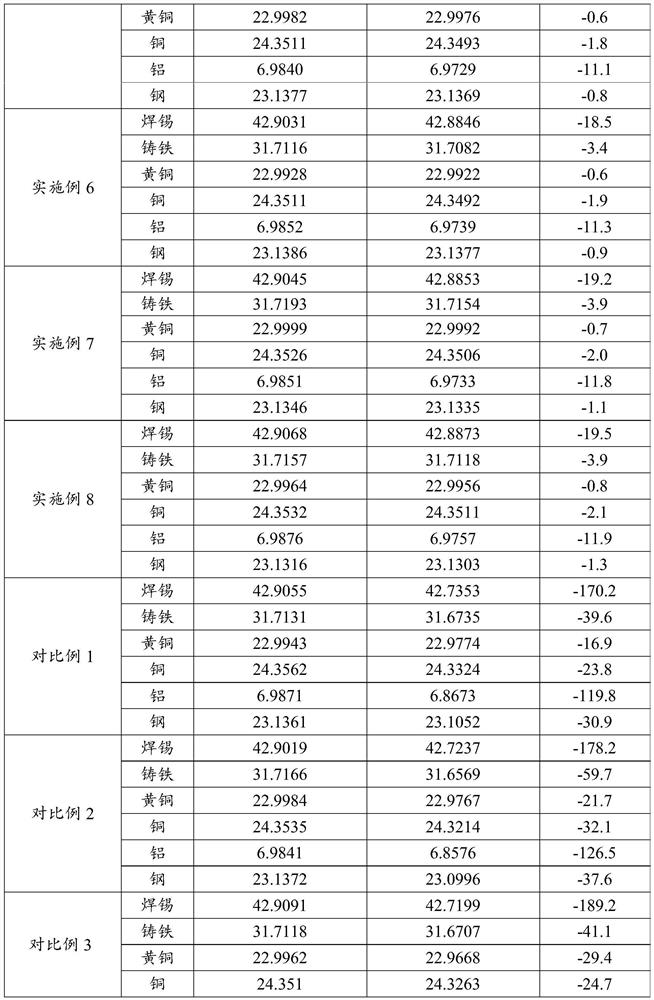

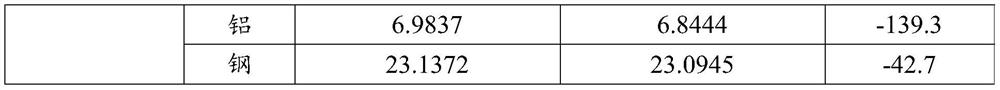

Examples

Embodiment 1

[0057] The present embodiment provides a kind of multi-metal surface protective agent, and its preparation method is as follows:

[0058] Preparation of film former:

[0059] Dissolve 5kg of benzotriazole in 5.5kg of ethanol to obtain a mixed solution for subsequent use;

[0060] Add 25kg of deionized water into the reaction kettle and heat it to 60°C with stirring, then add 15kg of undecanedioic acid, 10kg of dodecanedioic acid, 12kg of gluconic acid and 15kg of benzoic acid, heat up to 90°C after adding, add 15kg of triethanolamine and 3kg of ethanolamine, and continue to stir for 0.5h: then add the above mixed solution and raise the temperature to 110°C and stir for 1.5h, then cool down to normal temperature naturally to obtain the film-forming agent for later use.

[0061] Preparation of sealants:

[0062] After mixing 30kg of deionized water and 10kg of ammonium citrate evenly, add 20kg of sebacic acid and 10kg of adipic acid at 80°C, then raise the temperature to 88°C ...

Embodiment 2

[0070] The present embodiment provides a kind of multi-metal surface protective agent, and its preparation method is as follows:

[0071] Preparation of film former:

[0072] Dissolve 10kg of benzotriazole in 10kg of ethanol to obtain a mixed solution for subsequent use;

[0073] Add 20kg of deionized water into the reaction kettle and heat it up to 60°C with stirring, then add 20kg of undecanedioic acid, 15kg of dodecanedioic acid, 15kg of gluconic acid and 6kg of benzoic acid, heat up to 80°C after adding, add 20kg of triethanolamine and 8kg of ethanolamine, and continue to stir for 1.5h: then add the above mixed solution and raise the temperature to 120°C and stir for 2.5h, then cool down to normal temperature naturally to obtain the film-forming agent for later use.

[0074] Preparation of sealants:

[0075]After mixing 20kg of deionized water and 15kg of ammonium citrate evenly, add 25kg of sebacic acid and 15kg of adipic acid at 85°C, then raise the temperature to 90°C...

Embodiment 3

[0083] The present embodiment provides a kind of multi-metal surface protective agent, and its preparation method is as follows:

[0084] Preparation of film former:

[0085] Dissolve 8kg of benzotriazole in 7.2kg of ethanol to obtain a mixed solution for subsequent use;

[0086] Add 16kg of deionized water into the reactor and heat it to 60°C with stirring, then add 10kg of undecanedioic acid, 20kg of dodecanedioic acid, 8kg of gluconic acid and 10kg of benzoic acid, after the addition is complete, heat up to 100°C, add 10kg of triethanolamine and 5kg of ethanolamine, and continue to stir for 1.0h: then add the above mixed solution and raise the temperature to 130°C and stir for 2.0h, then cool down to normal temperature naturally to obtain the film-forming agent for later use.

[0087] Preparation of sealants:

[0088] After mixing 25kg of deionized water and 5kg of ammonium citrate evenly, add 22kg of sebacic acid and 20kg of adipic acid at 75°C, then raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com