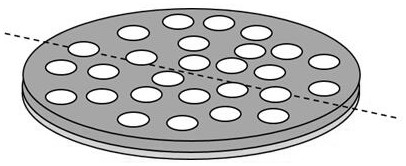

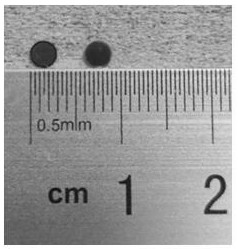

Transmission electron microscope micro-grid based on heavy ion irradiation, and preparation method thereof

A technology of transmission electron microscopy and heavy ions, applied in the manufacture of electrode systems, manufacture of discharge tubes/lamps, circuits, etc., can solve problems such as difficult large-scale preparation, unfavorable resolution, and complicated preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

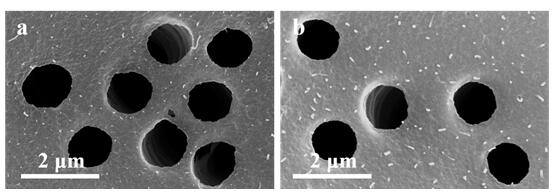

[0039] A method for preparing a transmission electron microscope microgrid based on heavy ion irradiation, the specific steps are as follows:

[0040] (1) Irradiation of polyethylene terephthalate PET film:

[0041] The high-energy heavy ions are accelerated on the heavy ion accelerator, and the high-energy heavy ions are used to irradiate the surface of the polyethylene terephthalate PET film vertically. The thickness of the polyethylene terephthalate PET film is 5 μm. Among them, the LET linear energy transfer value of the high-energy heavy ions in the polyethylene terephthalate PET film is greater than 4.5 eV / nm, and the number of high-energy heavy ions irradiated on the polyethylene terephthalate film is 2.0 ×10 10 ions / cm 2 .

[0042] (2) Etching of nanopores of polyethylene terephthalate PET film:

[0043] The irradiated polyethylene terephthalate PET film was immersed in a sodium hydroxide solution for chemical etching, wherein the concentration of the sodium hydro...

Embodiment 2

[0047] A method for preparing a transmission electron microscope microgrid based on heavy ion irradiation, the specific steps are as follows:

[0048] (1) Irradiation of polyethylene terephthalate PET film:

[0049] The high-energy heavy ions are accelerated on the heavy ion accelerator, and the high-energy heavy ions are used to irradiate the surface of the polyethylene terephthalate PET film vertically. The thickness of the polyethylene terephthalate PET film is 30 μm. Among them, the LET linear energy transfer value of the high-energy heavy ions in the polyethylene terephthalate PET film is greater than 4.5 eV / nm, and the number of high-energy heavy ions irradiated on the polyethylene terephthalate film is 1.0 ×10 5 ions / cm 2 ;

[0050] (2) Etching of nanopores of polyethylene terephthalate PET film:

[0051] The irradiated polyethylene terephthalate PET film was immersed in a sodium hydroxide solution for chemical etching, wherein the concentration of the sodium hydro...

Embodiment 3

[0055] A method for preparing a transmission electron microscope microgrid based on heavy ion irradiation, the specific steps are as follows:

[0056] (1) Irradiation of polyethylene terephthalate PET film:

[0057] The high-energy heavy ions are accelerated on the heavy ion accelerator, and the high-energy heavy ions are used to irradiate the surface of the polyethylene terephthalate PET film vertically. The thickness of the polyethylene terephthalate PET film is 20 μm. Among them, the LET linear energy transfer value of the high-energy heavy ions in the polyethylene terephthalate PET film is greater than 4.5 eV / nm, and the number of high-energy heavy ions irradiated on the polyethylene terephthalate film is 3.0 ×10 6 ions / cm 2 ;

[0058] (2) Etching of nanopores of polyethylene terephthalate PET film:

[0059] The irradiated polyethylene terephthalate PET film was immersed in a sodium hydroxide solution for chemical etching, wherein the concentration of the sodium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com