Aluminum-magnesium-silicon alloy monofilament and preparation method thereof

A silicon alloy and monofilament technology, which is applied in the field of aluminum alloy monofilament, can solve the problems of low conductivity and difficulty in meeting the requirements of energy-saving and loss-reducing power transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An aluminum-magnesium-silicon alloy monofilament, its components and their mass percentages are:

[0043] element magnesium silicon erbium Lanthanum (Cerium) boron Vanadium + Titanium + Chromium + Manganese aluminum Mass fraction / wt.%0.500.300.500.080.010.01 margin

[0044] Put the electrical pure aluminum ingot with a purity of 99.7% into a smelting furnace at 730°C for smelting;

[0045] After melting, add the aluminum-lanthanum master alloy and the aluminum-boron master alloy at 740°C, fully stir it after melting completely, and let it stand for 40 minutes;

[0046] Pour 4 / 5 of the melt from the upper part of the smelting furnace into another holding furnace, add pure magnesium, aluminum-silicon master alloy, and aluminum-erbium master alloy at 730℃, stir for 15min after complete melting, and let stand for 15min;

[0047] Blow in 0.5~0.8MPa nitrogen gas at 715℃ for 15min, leave it to stand for 20min, then slag off;

[0048] Pour the aluminum alloy liquid at 700℃ into the ...

Embodiment 2

[0051] An aluminum-magnesium-silicon alloy monofilament, the mass percentage of each component is:

[0052] element magnesium silicon erbium Lanthanum (Cerium) boron Vanadium + Titanium + Chromium + Manganese aluminum Mass fraction / wt.%0.700.500.400.050.0150.008 margin

[0053] The electrical pure aluminum ingot with a purity of 99.7% is added to the melting furnace at a melting temperature of 750°C; after the pure aluminum is completely melted, the aluminum-cerium master alloy is added at 730°C and the aluminum-boron master alloy is added at the same time, and then fully stirred after it is completely melted , Stand for 50min; pour the upper aluminum liquid of 4 / 5 melting furnace into another holding furnace, add pure magnesium, aluminum-silicon master alloy, aluminum-erbium master alloy at 750℃, stir for 10min after complete melting, and let stand for 20min . Make their final content as shown above. Blow in 0.5-0.8MPa nitrogen at 720°C for 10 minutes, and let it stand for...

Embodiment 3

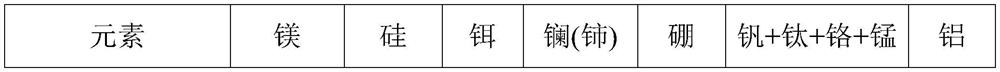

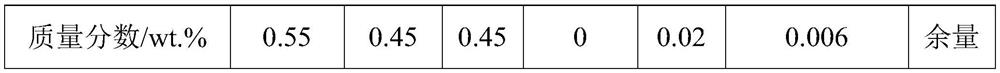

[0055] An aluminum-magnesium-silicon alloy monofilament, the mass percentage of each component is:

[0056] element magnesium silicon erbium Lanthanum (Cerium) boron Vanadium + Titanium + Chromium + Manganese aluminum Mass fraction / wt.%0.600.400.300.040.020.007 margin

[0057] The electrical pure aluminum ingot with a purity of 99.7% is added to the melting furnace, and the melting temperature is 740℃; after the pure aluminum is completely melted, the lanthanum-cerium mixed rare earth and the aluminum-boron intermediate alloy are added at 735℃. , Stand for 50min; pour the upper aluminum liquid of the 4 / 5 melting furnace into another holding furnace, add pure magnesium, aluminum-silicon master alloy, aluminum-erbium master alloy at 740℃, stir for 15min after complete melting, and stand for 20min . Make their final content as shown above. Blow in 0.5-0.8MPa nitrogen at 730°C for 15 minutes, and let it stand for 25 minutes before removing slag. The aluminum alloy liquid was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com