High-activity and anti-carbon-deposition composite catalyst, preparation method thereof and application thereof in methane dry gas reforming

A composite catalyst and anti-coking technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen/synthesis gas production, etc., can solve the problems of catalyst carbon deposition, nickel particle sintering, collapse, etc., to promote dispersion, Effect of suppressing sintering and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

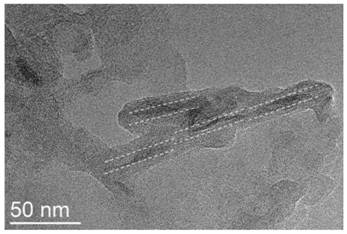

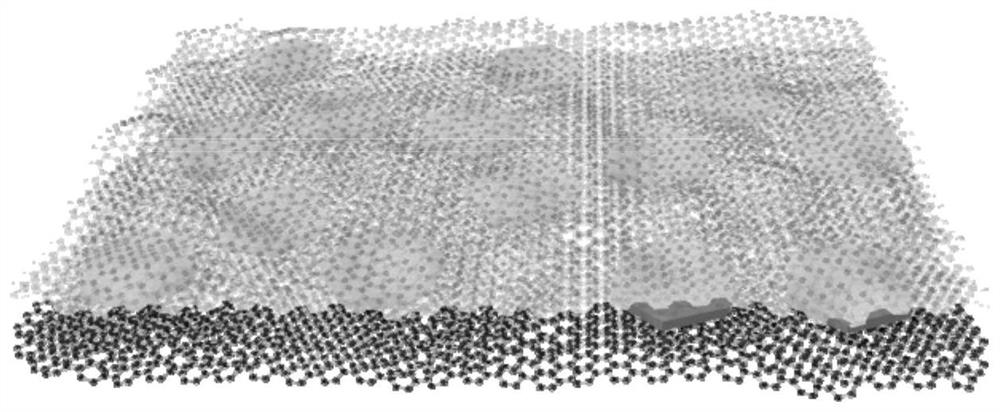

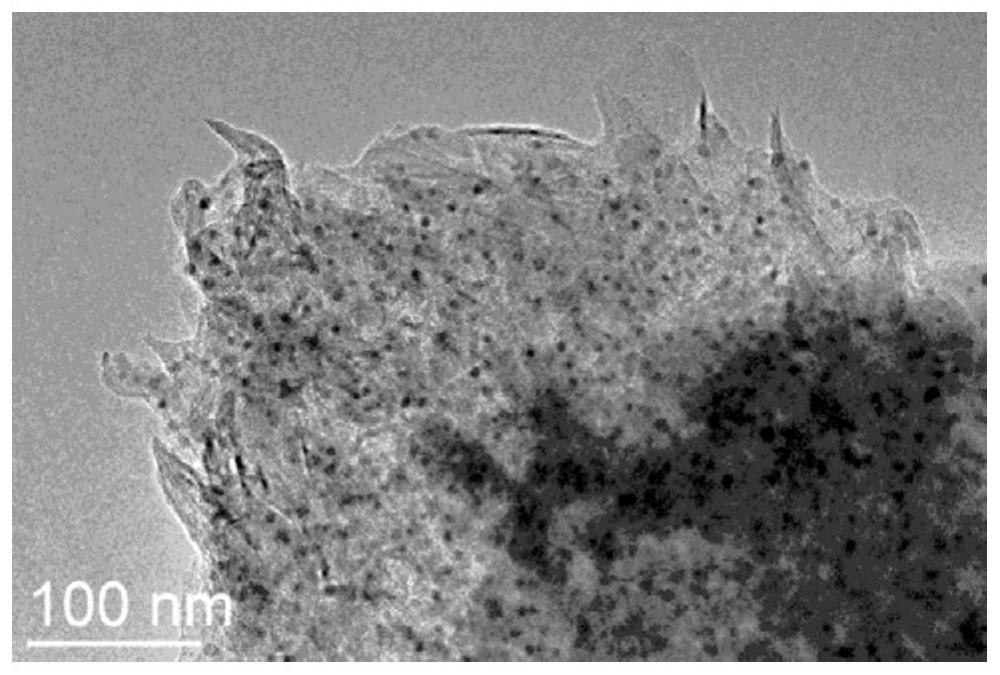

[0038] a) Preparation of NiMgAl layered double hydroxide nanosheets: Weigh 1.454g Ni(NO 3) 2 ·6H 2 O, 10.256gMg(NO 3 ) 2 ·6H 2 O, 5.627g Al(NO 3 ) 3 9H 2 O, dissolved in 50mL deionized water, take 200mL NaOH solution with a concentration of 0.1mol / L, add the dissolved nitrate solution into the NaOH solution, and treat at 30°C for 30min. The solution was then suction filtered and washed to pH=7. The obtained solid sample was dispersed in 225mL of deionized water, then loaded into a hydrothermal kettle, and treated at 100°C for 16h to obtain a NiMgAl layered double hydroxide sol.

[0039] b) Preparation of BN nanosheets: Weigh 0.2 g of hexagonal boron nitride and 4 g of urea, put them into a ball mill jar, and ball mill in a nitrogen atmosphere for 2.5 hours at 800 rpm. The urea is removed from the milled sample by dialysis to obtain a BN sol.

[0040] c) Preparation of BN-NiMgAl composite catalyst: drop layered double hydroxide sol and boron nitride sol into deionized ...

Embodiment 2

[0042] a) Preparation of NiCuAl layered double hydroxide nanosheets: Weigh 1.454g Ni(NO 3 ) 2 ·6H 2 O, 9.662g Cu(NO 3 ) 2 ·3H 2 O, 5.627g Al(NO 3 ) 3 9H 2 O, dissolved in 50mL deionized water, take 200mL NaOH solution with a concentration of 0.1mol / L, add the dissolved nitrate solution into the NaOH solution, and treat at 30°C for 30min. The solution was then suction filtered and washed to pH=7. The obtained solid sample was dispersed in 225mL of deionized water, then loaded into a hydrothermal kettle, and treated at 100°C for 16h to obtain a NiCuAl layered double hydroxide sol.

[0043] b) Preparation of BN nanosheets: Weigh 0.2g of hexagonal boron nitride and 4g of urea, put them into a ball mill jar, and ball mill in a nitrogen atmosphere for 2.5 hours at 800rpm. The urea is removed from the milled sample by dialysis to obtain a boron nitride sol.

[0044] c) Preparation of BN-NiCuAl composite catalyst: drop layered double hydroxide sol and boron nitride sol into d...

Embodiment 3

[0046] a) Preparation of NiFeAl layered double hydroxide nanosheets: Weigh 1.454g Ni(NO 3 ) 2 ·6H 2 O, 7.952 g FeCl 2 4H 2 O, 5.627g Al(NO 3 ) 3 9H 2 O, dissolved in 50mL of deionized water, take 200mL of NaOH solution with a concentration of 0.1mol / L, add the dissolved salt solution into sodium hydroxide solution, and treat at 30°C for 30min. The solution was then suction filtered and washed to pH=7. The obtained solid sample was dispersed in 225mL of deionized water, then loaded into a hydrothermal kettle, and treated at 100°C for 16h to obtain a NiFeAl layered double hydroxide sol.

[0047] b) Preparation of BN nanosheets: Weigh 0.2g of hexagonal boron nitride and 4g of urea, put them into a ball mill jar, and ball mill in a nitrogen atmosphere for 2.5 hours at 800rpm. The urea is removed from the milled sample by dialysis to obtain a boron nitride sol.

[0048] c) Preparation of BN-NiFeAl composite catalyst: drop layered double hydroxide sol and boron nitride sol i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com