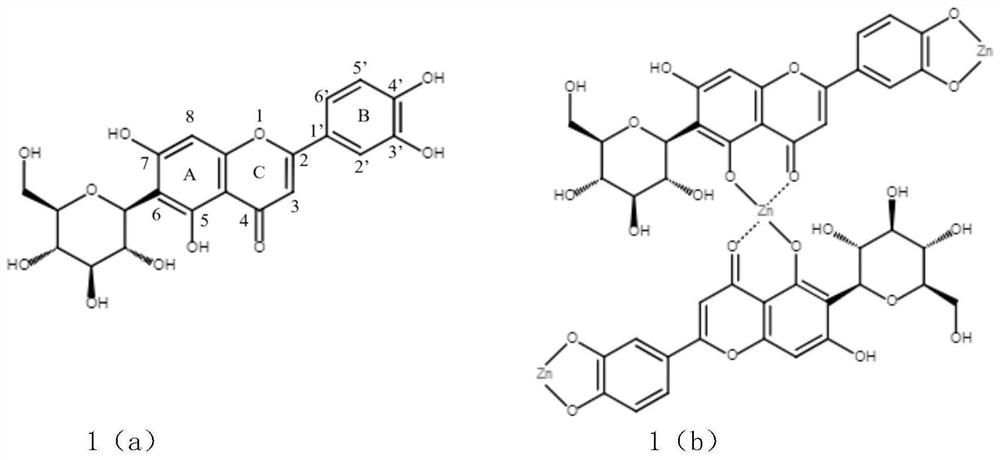

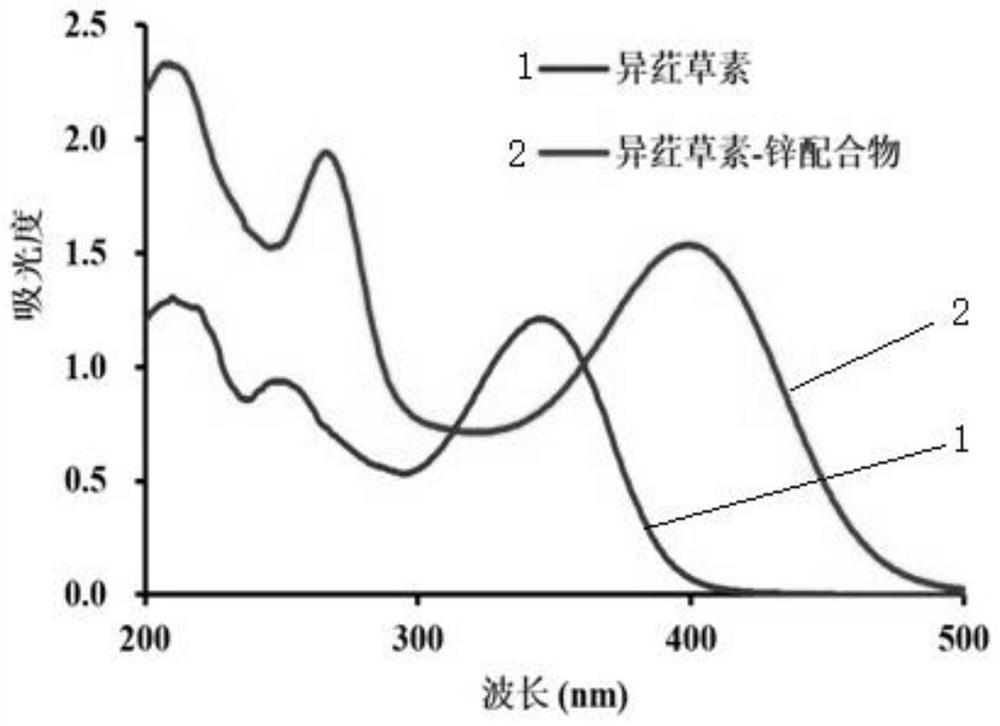

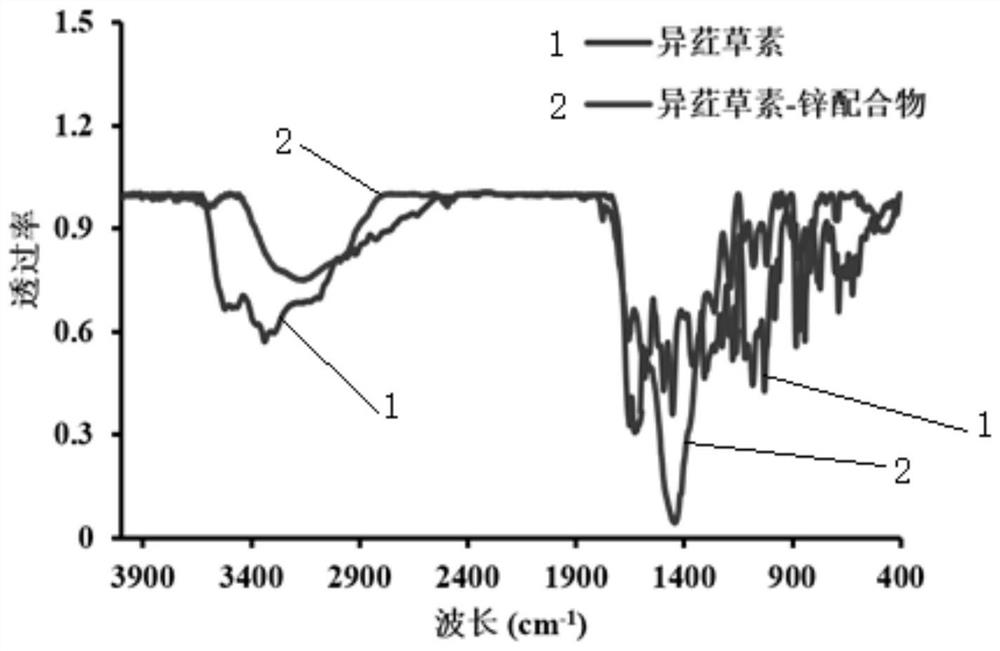

Water-soluble isoorientin-zinc complex as well as preparation method and application thereof

A technology of isoorientin and zinc complexes, which is applied to zinc organic compounds, pharmaceutical formulations, 2/12 groups of organic compounds without C-metal bonds, etc., can solve the problem of poor water solubility and insufficient physiological efficacy of isoorientin It can achieve the effect of good bacteriostatic effect, easy operation and good biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of water-soluble isoorientin-zinc complex, comprising the following steps:

[0034] 1) adding absolute ethanol to isoorientin, heating and dissolving in the dark, then adding zinc acetate, and adjusting the pH to 7.5-8.5 with NaOH-ethanol solution to obtain a mixed solution;

[0035] 2) The above-mentioned mixed solution is refluxed in a water bath, magnetically stirred, cooled, aged, precipitated and centrifuged to obtain a precipitate and a supernatant;

[0036] 3) The precipitate was washed with absolute ethanol and vacuum freeze-dried, and the obtained yellow solid powder was an isoorientin-zinc complex.

[0037] Further, in the step 1) the mass ratio of isorientin to zinc acetate is 2:3-4:6 (a range is best given), and the mass concentration of the NaOH-ethanol mixed solution is 2%.

[0038] Further, in the step 2), the temperature of the water bath is 50-65° C., and the stirring time is 6-10 hours.

[0039] An isorientin-zinc complex prepare...

Embodiment 1

[0046] A preparation method of water-soluble isoorientin-zinc complex, comprising the following steps:

[0047] 1) adding absolute ethanol to isoorientin, heating and dissolving in the dark, then adding zinc acetate, and adjusting the pH to 8 with NaOH-ethanol solution to obtain a mixed solution;

[0048] 2) The above-mentioned mixed solution is refluxed in a water bath, magnetically stirred, cooled, aged, precipitated and centrifuged to obtain the lower sediment and supernatant;

[0049] 3) The lower precipitate was washed with absolute ethanol, vacuum freeze-dried, and the obtained yellow solid powder was isoorientin-zinc complex.

[0050] In this embodiment, step 1) the mass ratio of isorientin to zinc acetate is 2:3, and the mass concentration of NaOH-ethanol mixed solution is 2%. The NaOH-ethanol mixed solution is that 2g of sodium hydroxide is dissolved in 98g of ethanol solution, and the mass concentration of the NaOH-ethanol mixed solution is 2%.

[0051] In this emb...

Embodiment 2

[0054] A preparation method of water-soluble isoorientin-zinc complex, comprising the following steps:

[0055] 1) adding absolute ethanol to isoorientin, heating and dissolving in the dark, then adding zinc acetate, and adjusting the pH to 8.5 with NaOH-ethanol solution to obtain a mixed solution;

[0056] 2) The above-mentioned mixed solution is refluxed in a water bath, magnetically stirred, cooled, aged, precipitated and centrifuged to obtain the lower sediment and supernatant;

[0057] 3) The lower precipitate was washed with absolute ethanol, vacuum freeze-dried, and the obtained yellow solid powder was isoorientin-zinc complex.

[0058] In this embodiment, step 1) the mass ratio of isorientin to zinc acetate is 3:4, and the mass concentration of NaOH-ethanol mixed solution is 2%. The NaOH-ethanol mixed solution is that 2g of sodium hydroxide is dissolved in 98g of ethanol solution, and the mass concentration of the NaOH-ethanol mixed solution is 2%.

[0059] In this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com