Preparation method of vanadium dioxide-based single crystal and vanadium dioxide-based single crystal

A technology of vanadium dioxide-based single crystal, which is applied in the preparation of vanadium dioxide-based single crystal, and in the field of vanadium dioxide-based single crystal, which can solve the problem of widening thermal hysteresis loop width, reducing the range of resistance change, difficult high-precision and fast response And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

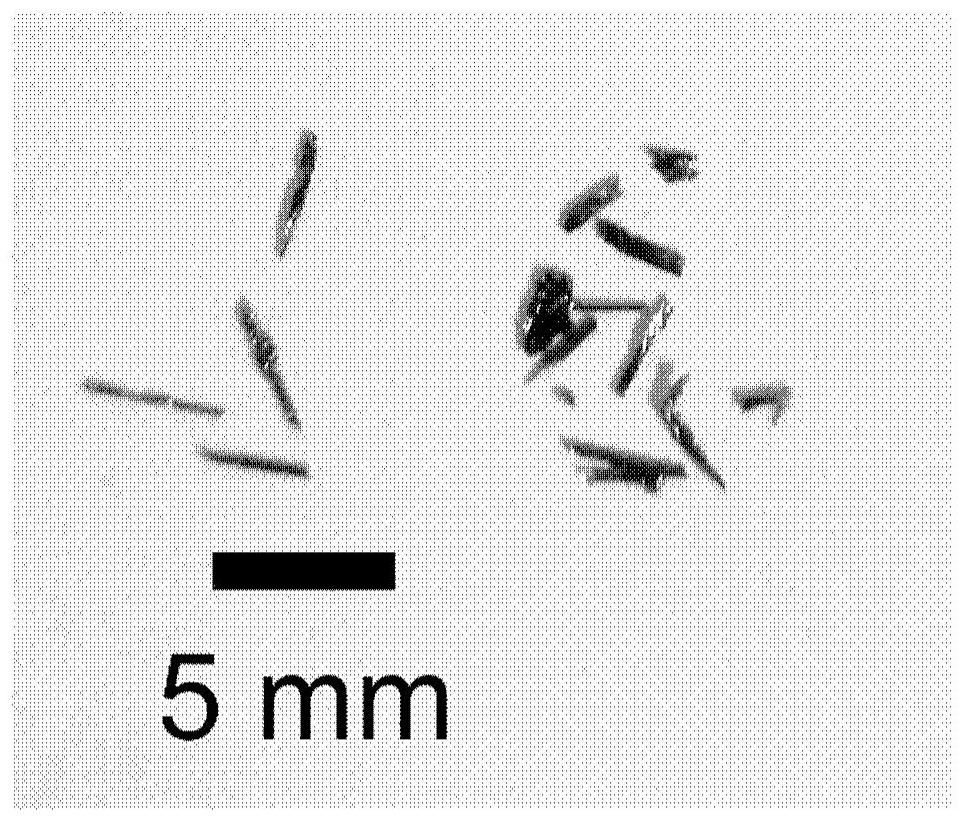

[0076] Add 300 mg of vanadium pentoxide powder into a circular single-opening quartz sample tube with an inner diameter of 1 cm and a length of 10 cm, and place it obliquely in a horizontal tubular annealing furnace sample chamber lined with quartz glass with a gas scrubber In the middle, place it obliquely, with an inclination angle of 25°, wash away the oxygen and water in the sample chamber by vacuuming three times and filling it with high-purity nitrogen, keep the airflow at 300 sccm, set the muffle furnace program as: heating at 10°C / min rate, rapidly raising the temperature to 1000°C for 60 hours, and then cooling down at a cooling rate of 10°C / min, the obtained vanadium dioxide single crystal is as follows figure 1 as shown, figure 1 Optical photographs of vanadium dioxide single crystals prepared in this example.

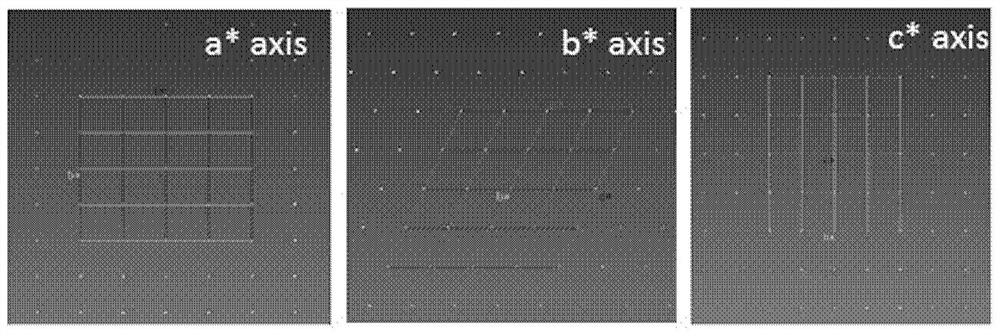

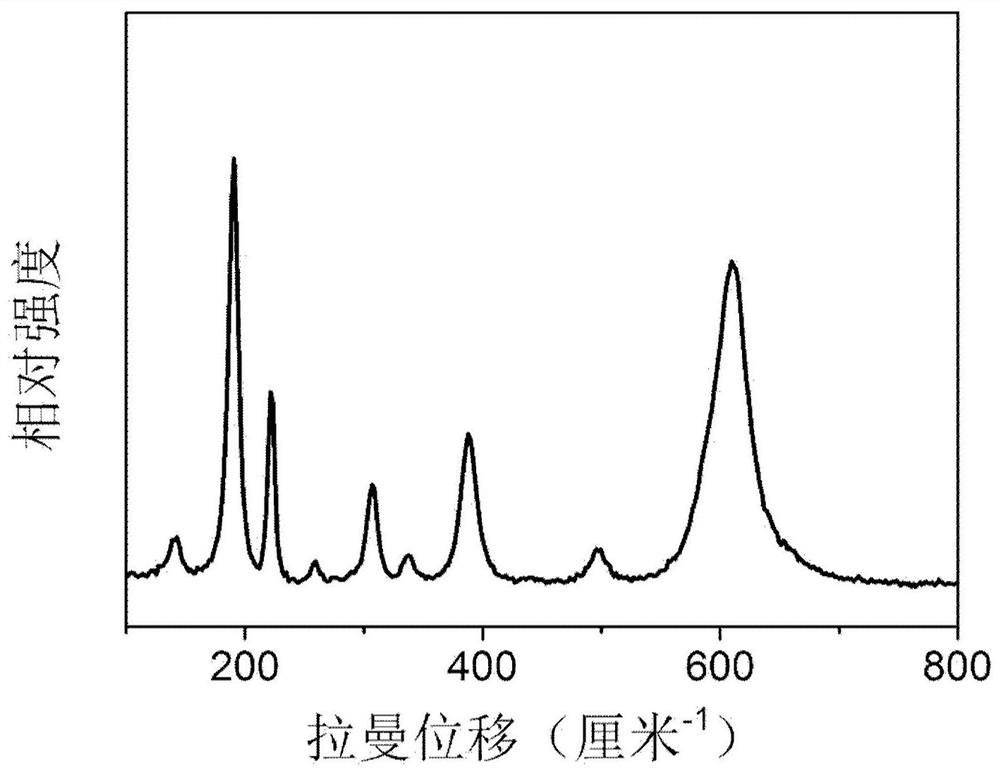

[0077] The single product quality and phase of the sample can be analyzed by four-circle diffractometer and Raman spectrometer, such as figure 2 and im...

Embodiment 2

[0081]Add 500 mg of ammonium metavanadate powder into a circular single-opened corundum sample tube with an inner diameter of 1.2 cm and a length of 12 cm, and place it obliquely in a horizontal tubular annealing furnace sample chamber lined with quartz glass with a gas scrubber In the middle, place it obliquely with an inclination angle of 15°, wash away the oxygen and water in the sample chamber by vacuuming three times and filling it with high-purity argon, keep the air flow at 200 sccm, set the muffle furnace program as: 10°C / min The heating rate is to rapidly raise the temperature to 1100°C for 60 hours, and then lower the temperature at a cooling rate of 15°C / min. The obtained sample was subjected to the same identification and detection analysis as in the above-mentioned Example 1, and it was determined that the obtained sample was a high-quality vanadium dioxide single crystal.

[0082] The insulator-metal phase transition behavior of the above-mentioned vanadium dioxi...

Embodiment 3

[0084] Add 300mg of vanadium pentoxide and 15mg of molybdenum trioxide powder into a circular single-opening quartz sample tube with an inner diameter of 1.2 cm and a length of 12 cm, and place it obliquely in a horizontal corundum-lined tube with a scrubber In the sample chamber of the tubular annealing furnace, the inclination angle is 25°. The oxygen and water in the sample chamber are washed away by vacuuming three times - filling with high-purity nitrogen, and the air flow is kept at 300 sccm. The muffle furnace program is set as: at 8°C / min heating rate, rapid heating to 980°C for 60 hours, and then cooling at a cooling rate of 8°C / min. The obtained sample was subjected to the same identification and detection analysis as in the above-mentioned Example 1, and it was determined that the obtained sample still maintained high crystal quality.

[0085] The insulator-metal phase transition behavior of the above-mentioned vanadium dioxide single crystal can be measured on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com