Lutetium fluoroselenite frequency doubling crystal as well as preparation and application thereof

A technology of lutetium fluoroselenite and lutetium selenite, applied in the field of double frequency crystal of lutetium fluoroselenite and its preparation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of 1#~8# samples

[0039] Mix lutetium, selenium, fluorine and water in a certain proportion to form raw materials, seal them in a polytetrafluoroethylene-lined hydrothermal reaction kettle, heat up to the crystallization temperature, and after a period of constant temperature, lower the system temperature at a certain rate. Slowly lower to room temperature, filter and wash to obtain the colorless needle-like Lu 3 F(SeO 3 ) 4 crystals.

[0040] The relationship between the types and proportions of raw materials in the initial mixture, crystallization temperature, crystallization time and sample number is shown in Table 1.

[0041] Table 1 Correspondence between samples, raw materials and synthesis conditions

[0042]

[0043]

[0044] Crystal structure analysis of samples 1#~8#

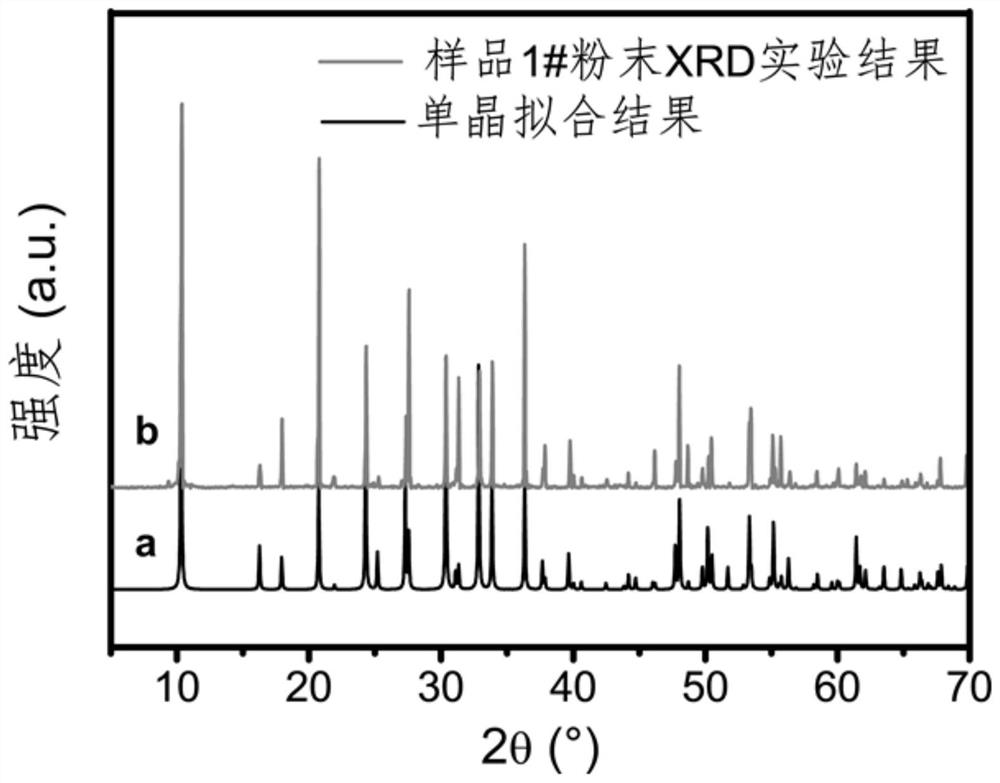

[0045] The structures of samples 1# to 8# were analyzed by single crystal X-ray diffraction and powder X-ray diffraction.

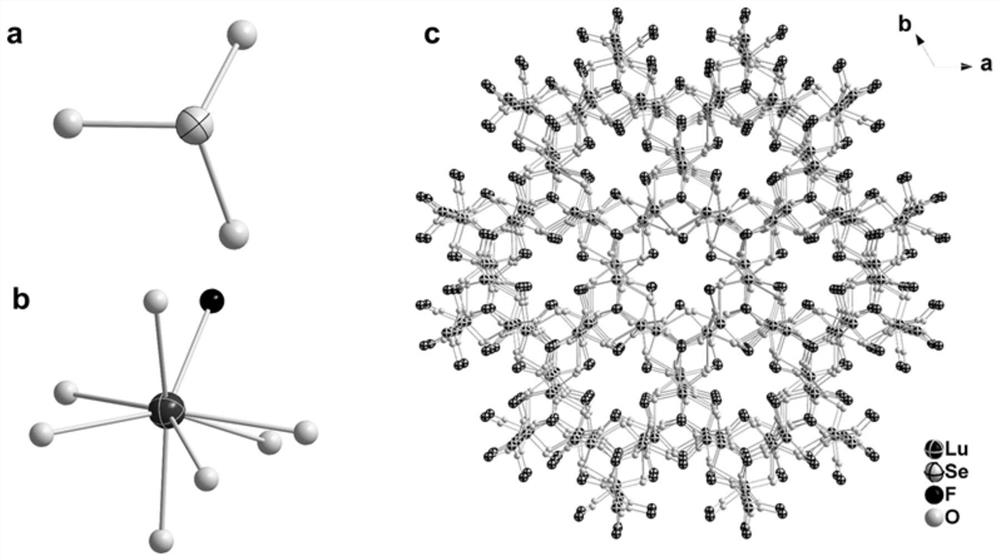

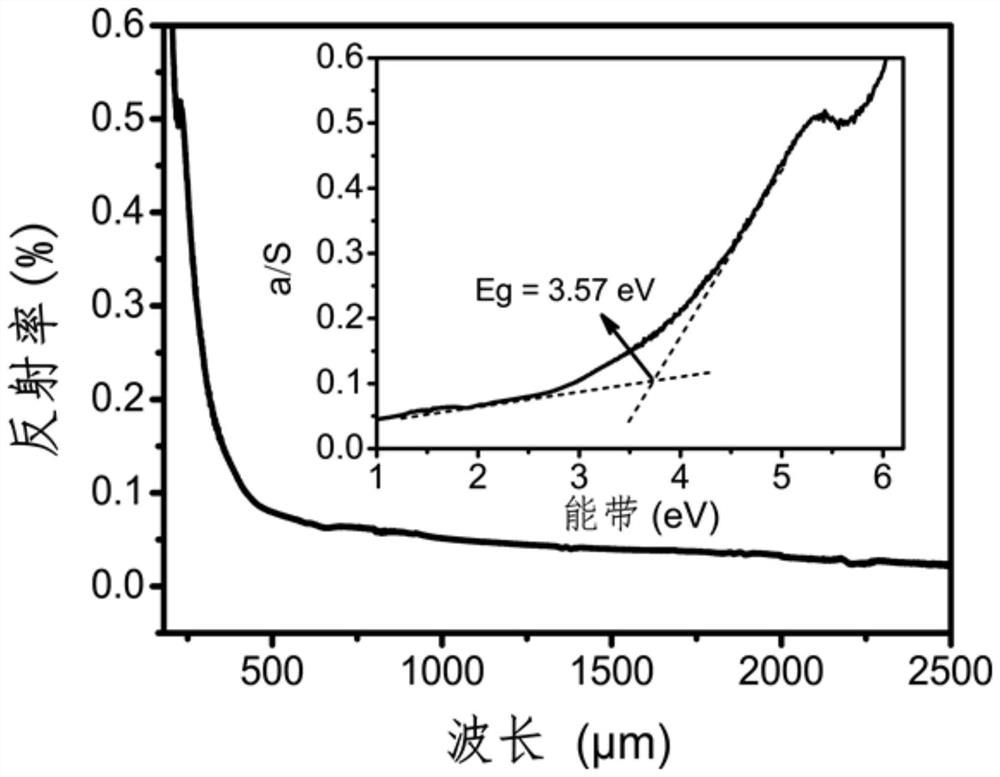

[0046] The single crystal X-ray diffraction w...

Embodiment 2

[0065] Adopt the preparation method similar to embodiment 1, difference is:

[0066] (1) The lutetium element that adopts is lutetium oxide, the selenium element that adopts is selenium dioxide, and the fluorine element that adopts is hydrofluoric acid, and wherein, the mol ratio of the lutetium element, selenium element, hydrofluoric acid and water in the initial mixture is Lu:Se:F:water=1.5:1:10:50;

[0067] (2) The adopted crystallization temperature is 220° C., and the crystallization time is 60 hours.

[0068] After testing, the obtained target product Lu 3 F(SeO 3 ) 4 The crystal has a large frequency doubling effect, and under 1064nm wavelength laser irradiation, the frequency doubling signal intensity is about 2.5 times that of the KDP crystal.

Embodiment 3

[0070] Adopt the preparation method similar to embodiment 1, difference is:

[0071] (1) The lutetium element used is lutetium fluoride, the selenium element used is selenium dioxide, and the fluorine element used is hydrofluoric acid, wherein the molar ratio of lutetium element, selenium element, hydrofluoric acid and water in the initial mixture Satisfy: Lu:Se:F:water=1.5:1:10:50;

[0072] (2) The adopted crystallization temperature is 230° C., and the crystallization time is 78 hours.

[0073] After testing, the obtained target product Lu 3 F(SeO 3 ) 4 The crystal has a large frequency doubling effect. Under 1064nm wavelength laser irradiation, the frequency doubling signal intensity is about 2.5 times that of KDP crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com