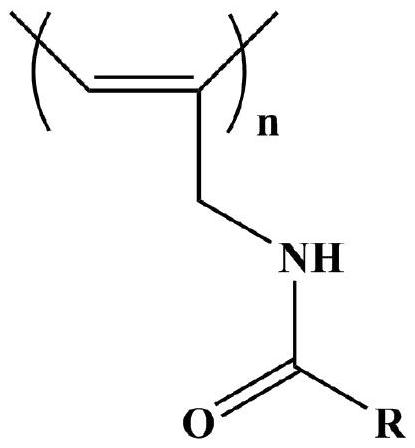

Infrared microwave compatible stealth composite material based on helical polyyne and its preparation method

A composite material and infrared microwave technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of difficulty in achieving excellent infrared stealth performance, single pore structure of multi-walled carbon nanotubes, and difficulty in achieving broadband absorbing performance. Achieve the effect of realizing infrared microwave compatible stealth performance, realizing dielectric loss characteristics, increasing multiple reflection and scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]145 mg of nickel nitrate hexahydrate and 255 mg of gallium nitrate hydrate were dissolved in a mixed solution of 32 mL of glycerin and 160 mL of isopropanol. Subsequently, the mixed solution was reacted at 180° C. for 6 h by a hydrothermal method, washed with ethanol, filtered, and vacuum-dried at 80° C. for 12 h to obtain nickel gallium glycerate. The nickel gallium glycerate was calcined at a temperature of 350° C. for 2 hours to obtain nickel gallium oxide nanomaterials. Stirring and dissolving 160 mg of nickel-gallium oxide nanomaterials in 200 mL of tris buffer solution, and then adding 40 mg of dopamine, stirred and reacted at room temperature for 6 h. After washing, filtering, and drying at 60° C. for 10 h, a polydopamine / nickel-gallium oxide nanomaterial with a core-shell structure is obtained;

[0024] Weigh 1.4g of cholic acid and dissolve it in 50mL of tetrahydrofuran, add 0.38mL of N-methylmorpholine and 0.43mL of isobutyl chloroformate at 0°C, and stir for ...

Embodiment 2

[0028] 87 mg of nickel nitrate hexahydrate and 153 mg of gallium nitrate hydrate were dissolved in a mixed solution of 20 mL of glycerin and 100 mL of isopropanol. Subsequently, the mixed solution was reacted at 160° C. for 10 h by a hydrothermal method, washed with ethanol, filtered, and vacuum-dried at 70° C. for 16 h to obtain nickel gallium glycerate. The nickel gallium glycerate was calcined at a temperature of 300° C. for 3 hours to obtain nickel gallium oxide nanomaterials. Stirring and dissolving 100 mg of nickel-gallium oxide nanomaterials in 120 mL of tris buffer solution, and then adding 25 mg of dopamine, stirred and reacted at room temperature for 7 h. After washing, filtering, and drying at 70°C for 12 hours, a polydopamine / nickel-gallium oxide nanomaterial with a core-shell structure is obtained;

[0029] Weigh 2.0g of ursodeoxycholic acid and dissolve it in 50mL of tetrahydrofuran, add 0.56mL of N-methylmorpholine and 0.65mL of isobutyl chloroformate at 0°C, a...

Embodiment 3

[0033] 116 mg of nickel nitrate hexahydrate and 255 mg of gallium nitrate hydrate were dissolved in a mixed solution of 26 mL of glycerin and 130 mL of isopropanol. Subsequently, the mixed solution was reacted at 150° C. for 12 h by a hydrothermal method, washed with ethanol, filtered, and vacuum-dried at 60° C. for 9 h to obtain nickel gallium glycerate. The nickel gallium glycerate was calcined at a temperature of 400° C. for 4 hours to obtain nickel gallium oxide nanomaterials. Stirring and dissolving 100 mg of nickel-gallium oxide nanomaterials in 125 mL of tris buffer solution, and then adding 25 mg of dopamine, stirred and reacted at room temperature for 8 h. After washing, filtering, and drying at 80° C. for 12 hours, a polydopamine / nickel-gallium oxide nanomaterial with a core-shell structure is obtained;

[0034] Weigh 1.6g of hyodeoxycholic acid and dissolve it in 50mL of tetrahydrofuran, add 0.45mL of N-methylmorpholine and 0.52mL of isobutyl chloroformate at 0°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com