Preparation method of flame-retardant plant-based wall decorative material

A decorative material and plant-based technology, which is applied in the field of preparation of flame-retardant plant-based wall decoration materials, can solve the problems of heavy waste water treatment load, high toxicity of decomposition products, and large smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a flame-retardant plant-based wall decoration material, the main scheme of which is as follows:

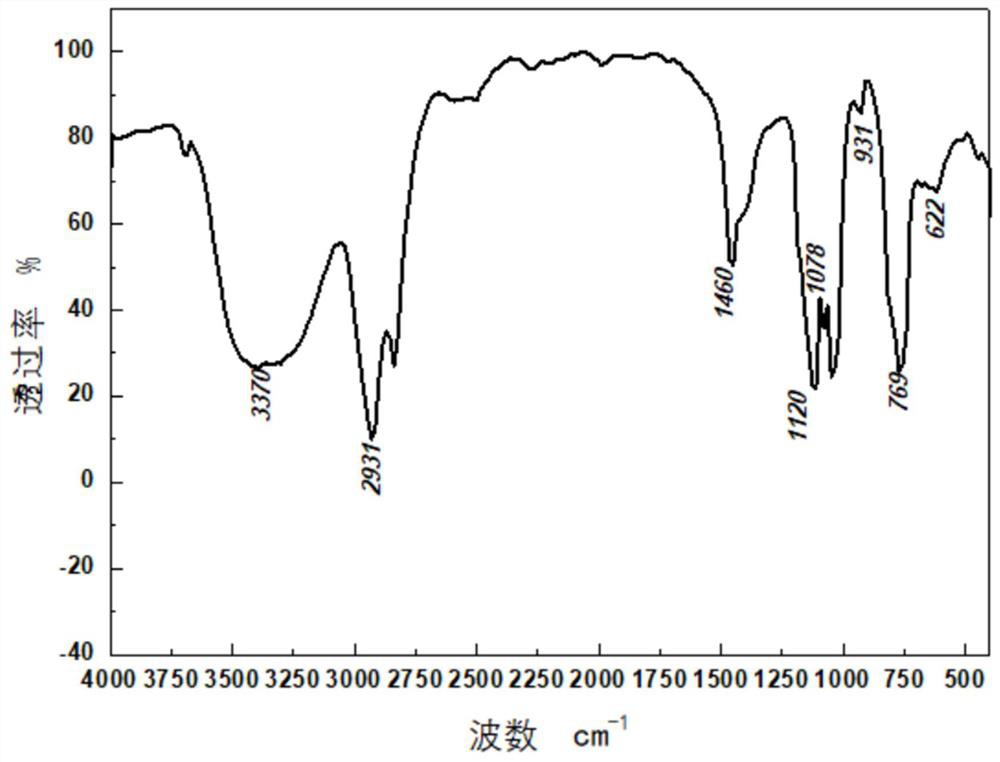

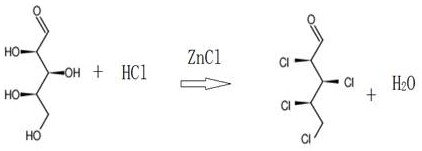

[0032] Step 1: According to the number of parts by mass, add 100 parts of plant fibers to hydrochloric acid with a mass percentage concentration of 10%, 4 parts of zinc chloride, control the temperature at 60°C, and process for 30 minutes. After the treatment, the plant fibers are dehydrated by spiral extrusion; After completion, add water for beating, the concentration of plant fiber is 5.2%, beating and dispersing for 20 minutes, stirring for 2 hours, and filtering to obtain chlorinated raw plant fiber;

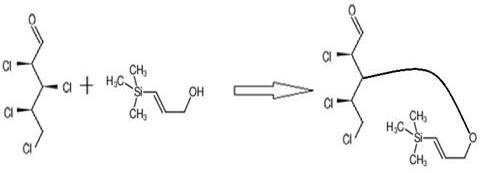

[0033] Step 2: Then mix well with 6 parts of 3-trimethylsilylpropenol and 100 parts of water, control the temperature at 60°C, and stir for 3 hours to obtain unsaturated silicon-based plant fibers;

[0034] Step 3: Then add 10 parts of magnesium hydroxide, 9.4 parts of diallyl dimethyl ammonium chloride, 0.1 part of potassium persulfate, stir evenl...

Embodiment 2

[0042] A method for preparing a flame-retardant plant-based wall decoration material, the main scheme of which is as follows:

[0043] Step 1: According to the number of parts by mass, 120 parts of plant fibers are added to hydrochloric acid with a mass percentage concentration of 12%, 5 parts of zinc chloride, the temperature is controlled at 65°C, and the treatment is carried out for 60 minutes. After the treatment, the plant fibers are dehydrated by spiral extrusion; After completion, add water for beating, the plant fiber concentration is 6.8%, beating and dispersing for 25 minutes, stirring for 4 hours, and filtering to obtain the chlorinated raw material plant fiber;

[0044] Step 2: Then mix with 9 parts of 3-trimethylsilylpropenol and 150 parts of water evenly, control the temperature at 69°C, and stir for 5 hours to obtain unsaturated silicon-based plant fibers;

[0045] Step 3: Then add 12 parts of magnesium hydroxide, 11 parts of diallyl dimethyl ammonium chloride, ...

Embodiment 3

[0053] A method for preparing a flame-retardant plant-based wall decoration material, the main scheme of which is as follows:

[0054] Step 1: According to the number of parts by mass, 150 parts of plant fibers are added to hydrochloric acid with a mass percentage concentration of 15%, 8 parts of zinc chloride, the temperature is controlled at 70°C, and the treatment is performed for 90 minutes. After the treatment, the plant fibers are dehydrated by spiral extrusion; After completion, add water for beating, the concentration of plant fiber is 8.7%, beating and dispersing for 40 minutes, stirring for 5 hours, and filtering to obtain the chlorinated raw material plant fiber;

[0055] Step 2: Then mix with 13 parts of 3-trimethylsilylpropenol and 200 parts of water evenly, control the temperature at 75°C, and stir for 7 hours to obtain unsaturated silicon-based plant fibers;

[0056] Step 3: Then add 15 parts of magnesium hydroxide, 15.8 parts of diallyl dimethyl ammonium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com