Lithium titanate silicon-based composite negative electrode material and preparation method thereof

A negative electrode material, lithium titanate technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of large expansion rate, small volume expansion, and low cycle life of the pole piece, and achieve high safety and small expansion , rate charge and discharge performance and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

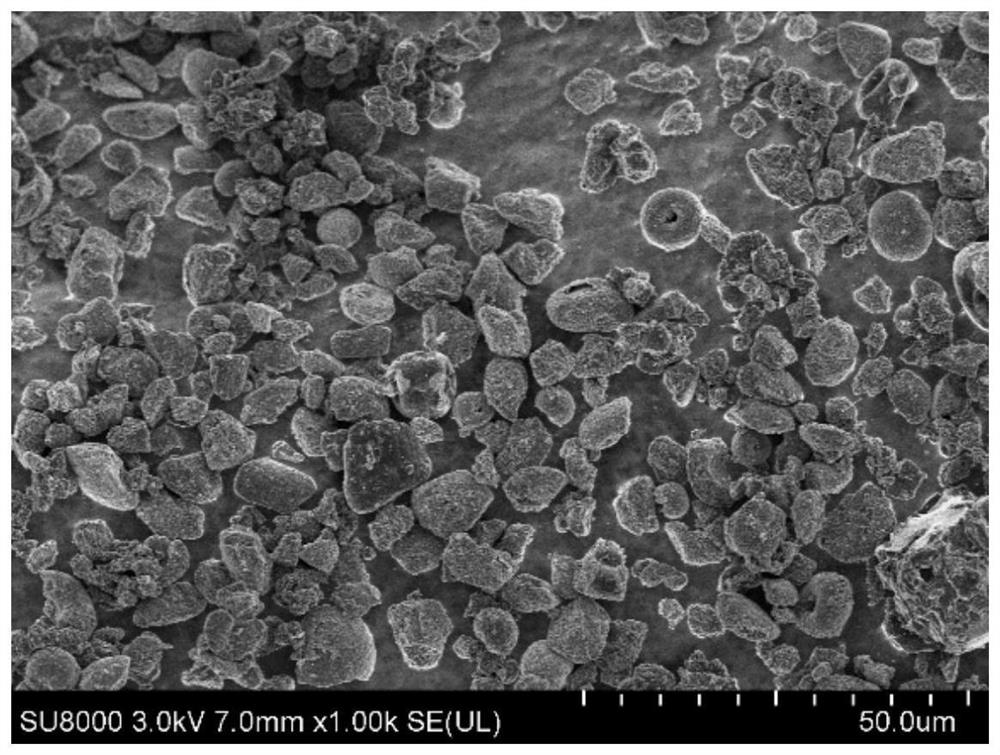

[0035] Evenly disperse silicon powder and lithium titanate with a mass ratio of 60:40 in ethanol, then add 20% dispersant, the dispersant is sodium dodecylbenzenesulfonate, and the above mixed solution is wetted in a nano grinder. Grinding by using 0.2mm zirconia beads as the grinding medium, and grinding for 10h at a speed of 1500rpm to obtain a suspension of nano-silicon / nano-lithium titanate with a median particle size of 100nm;

[0036] Add 10% pore-forming agent to the nano-silicon / nano-lithium titanate suspension, the pore-forming agent is polyvinylpyrrolidone, stir at a high speed for 1 hour, and the stirring speed is 1500rpm. After the stirring is completed, carry out spray drying. 120°C, the outlet temperature is 80°C, and the rotation speed of the atomizing disc is 15000rpm, thus obtaining the first precursor;

[0037] The first precursor is placed in a rotary furnace for chemical vapor deposition. Nitrogen gas is fed into the rotary furnace at a flow rate of 2L / min....

Embodiment 2

[0040] Evenly disperse silicon powder and lithium titanate with a mass ratio of 5:95 in ethanol, then add 1% dispersant, the dispersant is sodium dodecylbenzenesulfonate, and the above mixed solution is wetted in a nano grinder. Grinding using the grinding medium, using 0.05mm zirconia beads as the grinding medium, grinding for 24 hours at a speed of 1500rpm to obtain a suspension of nano-silicon / nano-lithium titanate with a median particle size of 30nm;

[0041] Add 5% pore-forming agent to the nano-silicon / nano-lithium titanate suspension, the pore-forming agent is a mixture of glucose and sucrose, stir at a high speed for 2 hours, and the stirring speed is 2000rpm. After the stirring is completed, spray dry. The temperature is 120°C, the outlet temperature is 75°C, and the rotation speed of the atomizing disc is 15000rpm, thus obtaining the first precursor;

[0042] The first precursor was placed in a rotary furnace for chemical vapor deposition. Helium was fed into the rot...

Embodiment 3

[0045] Evenly disperse silicon powder and lithium titanate with a mass ratio of 95:5 in the mixed solution of ethanol and propanol, then add 5% dispersant, the dispersant is polyoxyethylene fatty acid ester, and the above mixed solution is nano-grinded Carry out wet grinding in the machine, the grinding medium is 4mm zirconia beads, and grind for 5h at a speed of 500rpm to obtain a nano-silicon / nano-lithium titanate suspension with a median particle size of 200nm;

[0046] Add 15% pore-forming agent to the nano-silicon / nano-lithium titanate suspension, the pore-forming agent is polyvinylpyrrolidone, stir at a high speed for 3 hours, and the stirring speed is 1000rpm. After the stirring is completed, carry out spray drying. 200°C, the outlet temperature is 120°C, and the rotation speed of the atomizing disc is 15000rpm, thus obtaining the first precursor;

[0047] The first precursor is placed in a rotary furnace for chemical vapor deposition. Nitrogen gas is fed into the rotar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com