Photosensitive composite resin for photocuring 3D printing and preparation method thereof

A 3D printing and composite resin technology, applied in the direction of additive processing, etc., to achieve the effect of improving mechanical properties, improving interface bonding performance, and improving warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

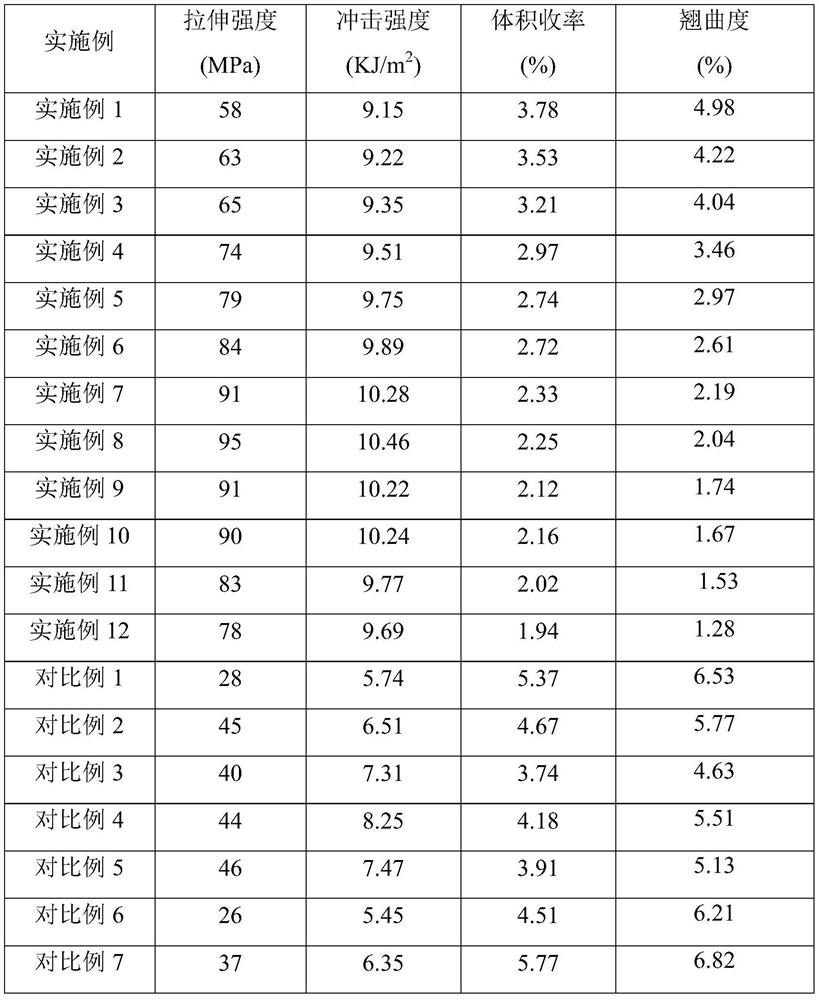

Examples

Embodiment 1

[0049] A photosensitive composite resin for photocuring 3D printing, made of the following components calculated in parts by mass: 50 parts of polyurethane acrylate; 20 parts of bisphenol A epoxy resin; 15 parts of glycidyl methacrylate; benzoin 1 part of dimethyl ether; 3 parts of diphenyliodohexafluorophosphate; 0.5 part of disulfide bond-mercapto modified carbon fiber; 0.5 part of silicone-propylene oxide copolymer.

[0050] The preparation method of the photosensitive composite resin for photocuring 3D printing includes the following steps:

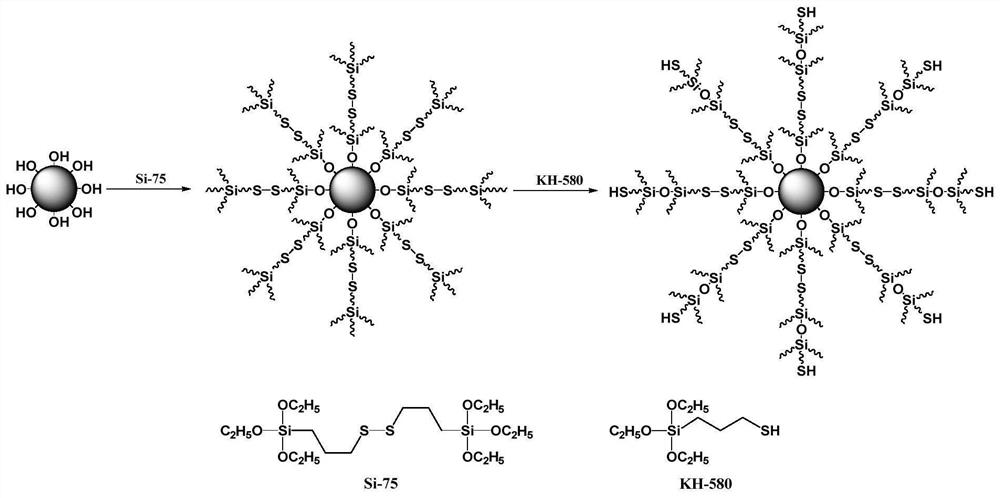

[0051] Dry and activate 100g of carbon oxide fiber at 110°C, then uniformly disperse the carbon oxide fiber in 500mL of absolute ethanol, then add 50g of silane coupling agent containing disulfide bonds, deionized water with 15% weight of silane coupling agent, concentrated Adjust the pH of the system to 2 with hydrochloric acid, stir and reflux at 65°C for 4 hours; then add 25g of mercapto-containing silane coupling agent, continue t...

Embodiment 2

[0054] A photosensitive composite resin for photocuring 3D printing, made of the following components calculated in parts by mass: 50 parts of polyurethane acrylate, 25 parts of bisphenol A epoxy resin, 15 parts of glycidyl methacrylate, 1 - 1 part of hydroxycyclohexyl phenone, 4 parts of diphenyl iodine hexafluorophosphate, 1 part of disulfide bond-mercapto modified carbon fiber prepared in Example 1, and 1 part of silicone-propylene oxide copolymer.

[0055] The preparation method of the above-mentioned photosensitive composite resin for photocuring 3D printing is the same as that of Example 1, except that the components are replaced.

Embodiment 3

[0057] A photosensitive composite resin for photocuring 3D printing, made of the following components calculated in parts by mass: 50 parts of polyurethane acrylate, 30 parts of bisphenol A epoxy resin, 15 parts of glycidyl methacrylate, benzoin 1 part of dimethyl ether, 1 part of 1-hydroxycyclohexyl benzophenone, 6 parts of diphenyl iodine hexafluorophosphate, 5 parts of disulfide bond-mercapto modified nano-titanium dioxide, and 1.5 parts of organosilicon-propylene oxide copolymer.

[0058] The preparation method of the above-mentioned photosensitive composite resin for photocuring 3D printing is the same as that of Example 1, except that carbon fibers are replaced with nano-titanium dioxide to obtain disulfide bond-mercapto-modified nano-titanium dioxide, and other components are replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com