Infrared barrier composition and preparation method thereof

A technology of infrared blocking and composition, applied in the direction of coating and other directions, can solve the problems of unsatisfactory infrared thermal insulation function, many layers, difficult to realize industrialization, etc., and achieve good infrared blocking effect, simple preparation method, and easy industrialization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

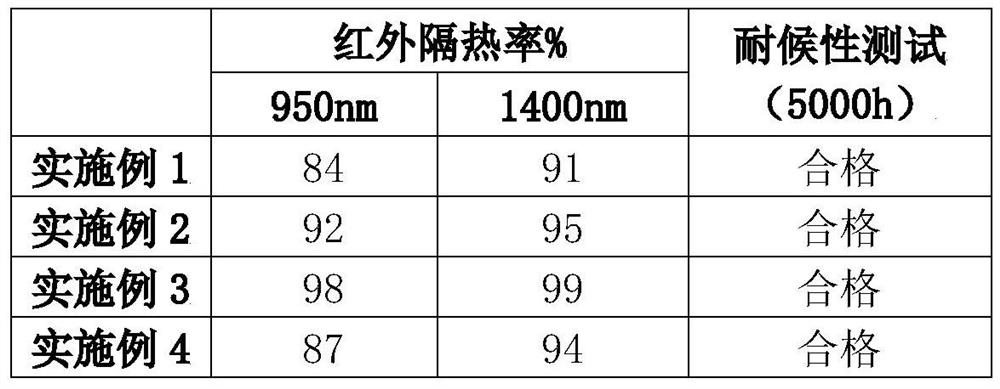

Examples

Embodiment 1

[0020] The first step: After mixing tungsten tetrachloride, titanium tetrachloride and tin tetrachloride in a weight ratio of 25:45:30, add sodium dodecylsulfonate with 1wt% of the total amount of inorganic chloride mixture , continue to mix evenly; select the zirconium beads with a particle size of 1 mm, mix the zirconium beads, absolute ethanol and inorganic chlorinated mixture in a mass ratio of 4:1:2, and then wet ball mill for 10 hours;

[0021] Step 2: After drying and crushing the product obtained in Step 1, put it into a sintering furnace and heat it up to 800°C at a rate of 5°C / s for calcination. The cooling rate is cooled to room temperature;

[0022] Step 3: Grind the product obtained in Step 2 again, and filter through a 400-mesh vibrating sieve to obtain a composition with an infrared blocking function.

Embodiment 2

[0024] The first step: After mixing tungsten tetrachloride, titanium tetrachloride and tin tetrachloride uniformly in the ratio of 30:40:30, add dodecylbenzenesulfonic acid of 1.5wt% of the total amount of inorganic chlorination mixture Sodium, continue to mix evenly; select zirconium beads with a particle size of 1 mm, mix the zirconium beads, isopropanol and inorganic chlorinated mixture evenly at a mass ratio of 4:1:2, and then wet ball mill for 12 hours;

[0025] Step 2: After drying and crushing the product obtained in Step 1, put it into a sintering furnace and heat it up to 900°C at a rate of 6°C / s for calcination. The cooling rate is cooled to room temperature;

[0026] Step 3: Grind the product obtained in Step 2 again, and filter through a 400-mesh vibrating sieve to obtain a composition with an infrared blocking function.

Embodiment 3

[0028] The first step: After mixing tungsten tetrachloride, titanium tetrachloride and tin tetrachloride uniformly in the ratio of 45:40:15, add sodium cetyl sulfonate of 2wt% of the total amount of inorganic chloride mixture, Continue to mix evenly; select zirconium beads with a particle size of 2 mm, mix the zirconium beads, propanol and inorganic chlorinated mixture evenly according to the mass ratio of 4:1:2, and wet ball mill for 14 hours;

[0029] Step 2: After drying and crushing the product obtained in Step 1, put it into a sintering furnace and heat it up to 1000°C at a rate of 7°C / s for calcination. The cooling rate is cooled to room temperature;

[0030] Step 3: Grind the product obtained in Step 2 again, and filter through a 400-mesh vibrating sieve to obtain a composition with an infrared blocking function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com