Wollastonite-loaded strontium and lanthanum solid base catalyst and preparation method and application thereof

A solid base catalyst, wollastonite technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex processes, leaching deactivation, raw material oil High quality requirements, etc., to achieve the effect of wide sources and simple and feasible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a second aspect, the present invention provides a method for preparing the solid base catalyst, comprising the following steps:

[0027] Add strontium source, lanthanum source and wollastonite powder to water, stir and impregnate;

[0028] The impregnated product is dried, calcined and activated to obtain a solid base catalyst.

[0029] In some embodiments, the strontium source is a compound soluble in water and the cation is a strontium ion, such as strontium chloride, strontium nitrate, and the like.

[0030] In some embodiments, the lanthanum source is a compound soluble in water and the cation is a lanthanum ion, such as lanthanum chloride, lanthanum nitrate, and the like.

[0031] In order to reduce the influence of anions on the catalyst preparation process and catalytic effect, the strontium source and the lanthanum source are preferably nitrates.

[0032] In some embodiments, during the impregnation process, the concentration of the strontium salt solution ...

Embodiment 1

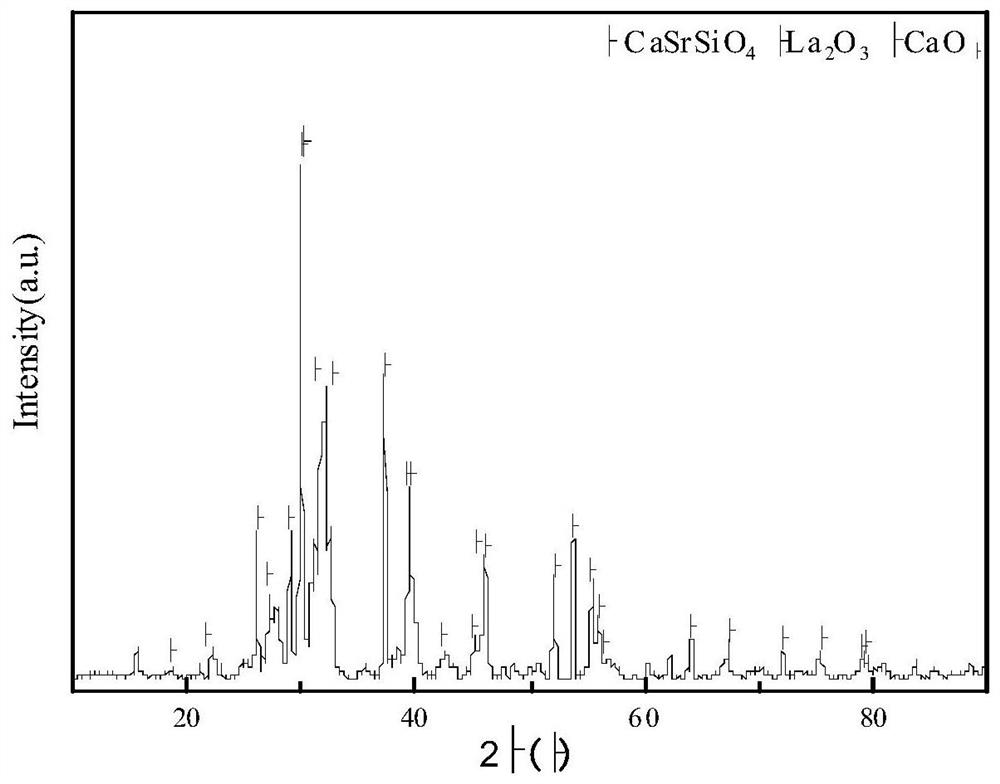

[0050] Weigh 12g of natural wollastonite ore powder, 14.81g of strontium nitrate (Sr(NO) in turn. 3 ) 2 ·4H 2 O) and 9.75g lanthanum nitrate (La(NO) 3 ) 3 ·xH 2 O) was added to 100 mL of deionized water, stirred and immersed for 0.5 h to obtain a mixed solution. The beaker of the mixed solution was placed in a water bath with a stirring device, and evaporated to dryness in a water bath at 80°C. The obtained catalyst precursor was dried at 120 °C for 12 h, and then calcined and activated at a heating rate of 5 °C / min from 20 °C to 900 °C for 5 h, to obtain a wollastonite supported with a strontium / lanthanum molar ratio of 7 / 3 Highly stable solid base catalysts for strontium and lanthanum.

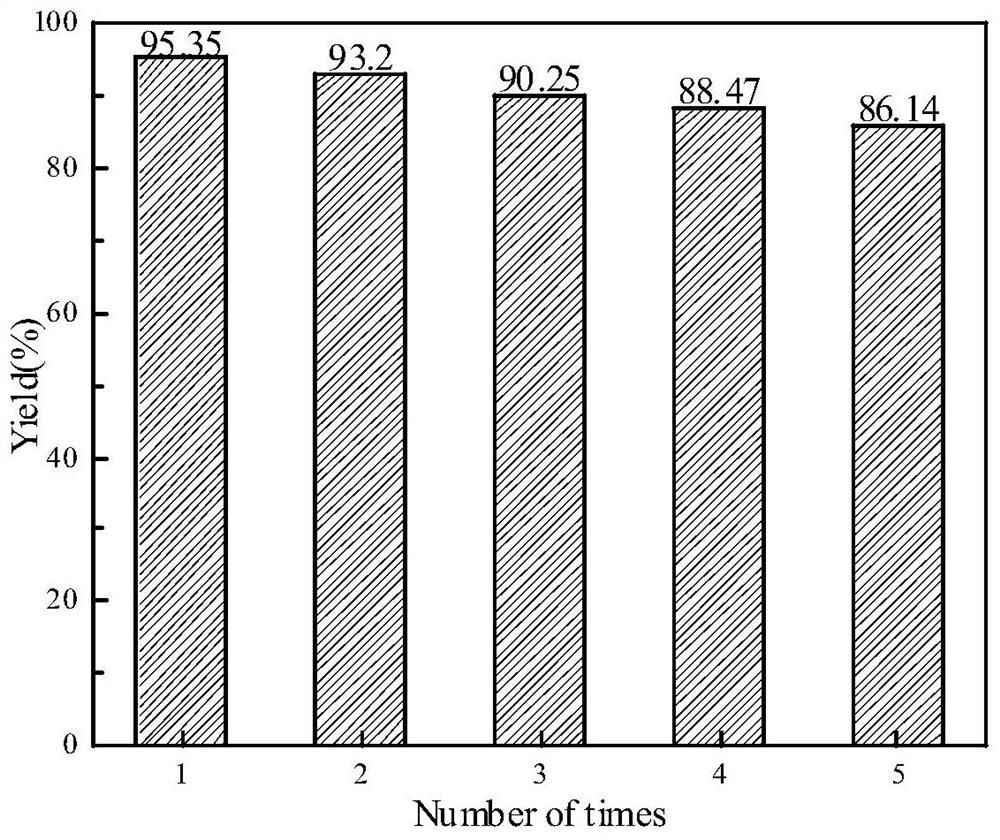

[0051] 10.5 g of methanol, 20 g of palm oil and 1.6 g of catalyst were successively added to the autoclave, and heated to 150° C. for 3 h under continuous stirring at a rotational speed of 1200 r / min. The solid catalyst was separated from the reaction product by a centrifuge, the liqu...

Embodiment 2

[0056] Weigh 12g of natural wollastonite ore powder, 19.05g of strontium nitrate (Sr(NO) in turn. 3 ) 2 ·4H 2 O) and 3.25g lanthanum nitrate (La(NO) 3 ) 3 ·xH 2 O) was added to 100 mL of deionized water, stirred and immersed for 0.5 h to obtain a mixed solution. The beaker of the mixed solution was placed in a water bath with a stirring device, and evaporated to dryness in a water bath at 80°C. The obtained catalyst precursor was dried at 120 °C for 12 h, and then calcined and activated at a heating rate of 5 °C / min from 20 °C to 900 °C for 5 h, to obtain a wollastonite supported with a strontium / lanthanum molar ratio of 9 / 1. Highly stable solid base catalysts for strontium and lanthanum.

[0057] 10.5 g of methanol, 20 g of palm oil and 1.6 g of catalyst were successively added to the autoclave, and heated to 150° C. for 3 h under continuous stirring at a rotational speed of 1200 r / min. The solid catalyst was separated from the reaction product by a centrifuge, the liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com