Antimony-doped tin oxide-manganese oxide composite catalyst for room-temperature catalytic oxidation of formaldehyde and preparation method thereof

An antimony-doped tin oxide, composite catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high complete degradation temperature, low resistivity, The problem of low catalytic efficiency at room temperature, etc., can improve the catalytic activity, the operation is convenient and feasible, and the redox activity can be enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of Manganese Oxide Catalyst by Hydrothermal Method

[0059] Dissolve 1.0 g of potassium permanganate and 0.8 g of ammonium oxalate solid in deionized water and mix, stir magnetically at room temperature for 15 minutes to dissolve to obtain a mixed solution; transfer the mixed solution to a 100 mL high-pressure Teflon-lined In the reaction kettle, then hydrothermally react at 100°C for 12h. After the reaction is completed, cool to room temperature naturally, and then centrifuge to obtain the precipitate. The precipitate is exchanged and washed with water and absolute ethanol for 3 times, and then dried at 80°C. 8h obtains manganese oxide catalyst (MnO 2 ).

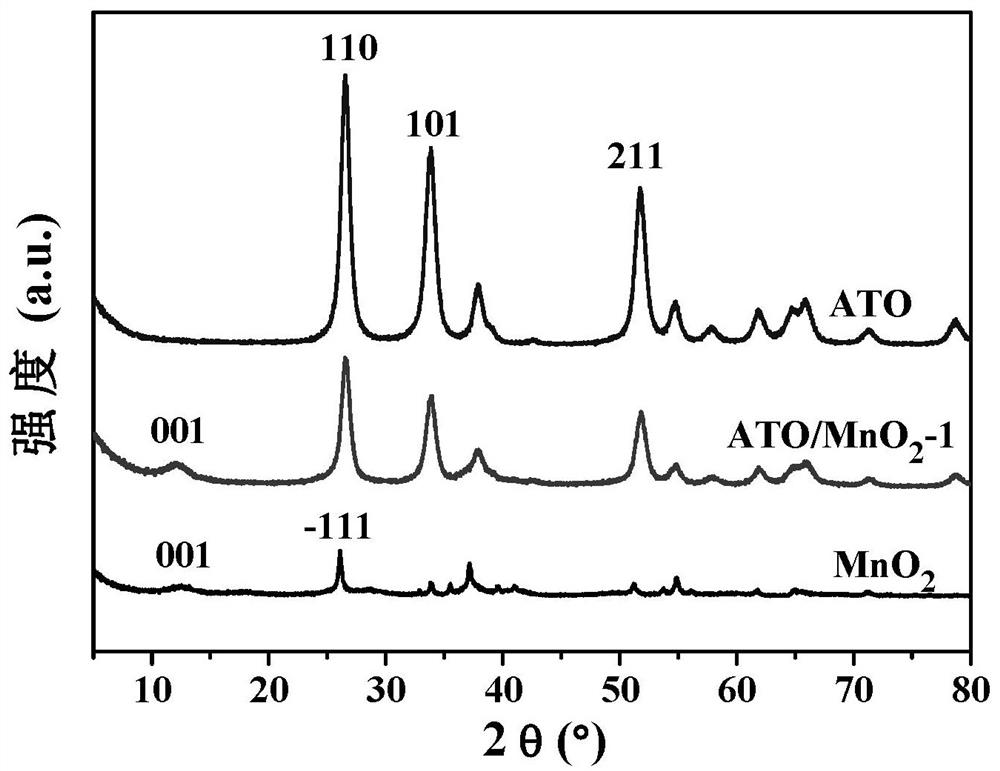

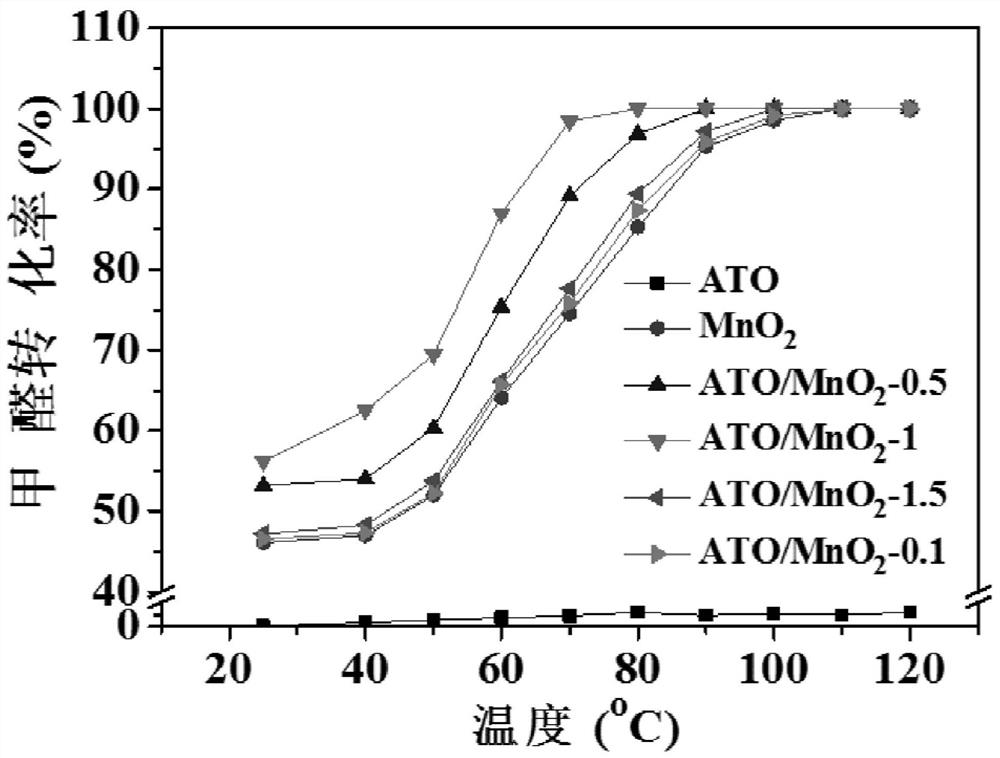

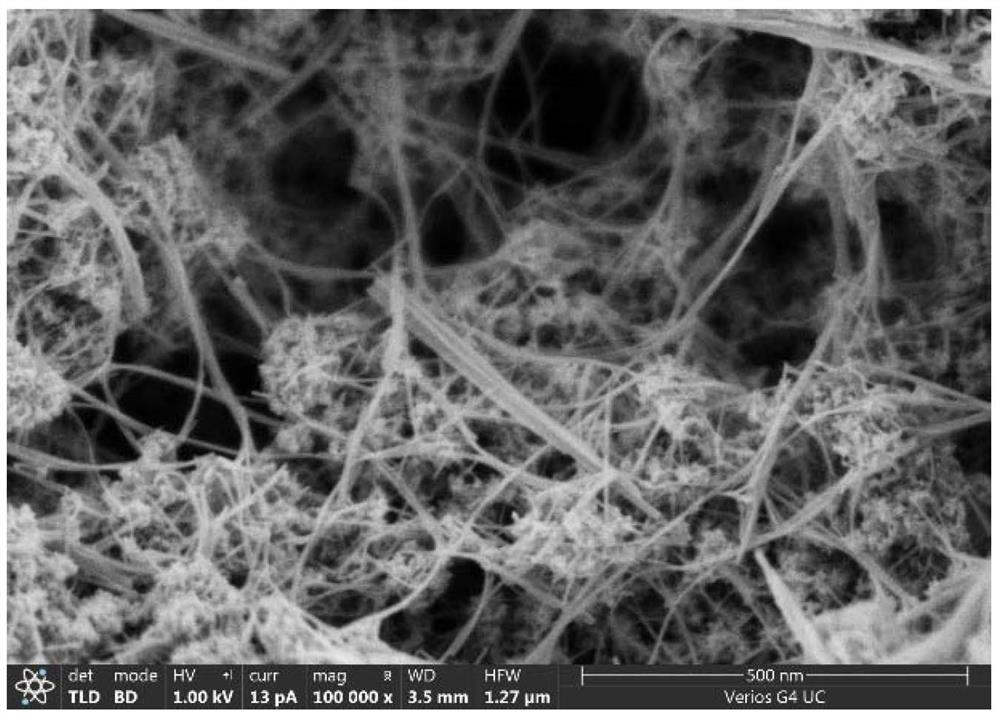

[0060] Depend on figure 1 and image 3 It can be seen that the as-prepared MnO was shown by X-ray diffraction and scanning electron microscopy 2 The catalyst is composed of flaky birnessite-type manganese oxide and fibrous birnessite-type manganese oxide, which are connected to each other to form a sp...

Embodiment 2

[0067] Hydrothermal treatment of antimony-doped tin oxide nanoparticles

[0068] Antimony-doped tin oxide nanoparticles (purchased from Shanghai Institute of Ceramics, Chinese Academy of Sciences, SnO 2 : Sb 2 o 3 =9: 1) was added to deionized water and mixed, and ultrasonically dispersed for 30 minutes to obtain a mixed solution; the mixed solution was transferred to a 100mL autoclave with a polytetrafluoroethylene liner, and then placed in water at 100°C Heat the reaction for 12 hours. After the reaction is completed, naturally cool to room temperature, and then centrifuge to obtain the precipitate. The precipitate is exchanged and washed with water and absolute ethanol for 3 times, and then dried at 70°C for 8 hours to obtain the antimony-doped oxidation product after hydrothermal treatment. Tin nanoparticles (ATO).

[0069] Depend on figure 1 and Figure 4 It can be known that the X-ray diffraction and scanning electron microscopy show that the phase of the ATO nanopa...

Embodiment 3

[0076] An antimony-doped tin oxide-manganese oxide composite catalyst for catalytic oxidation of formaldehyde at room temperature, the antimony-doped tin oxide-manganese oxide composite catalyst includes antimony-doped tin oxide nanoparticles, manganese oxide nanowires and manganese oxide nanosheets.

[0077] The preparation method of described antimony-doped tin oxide-manganese oxide composite catalyst specifically comprises the following steps:

[0078] 1) Disperse 0.3 g of antimony-doped tin oxide nanoparticles in 40 mL of deionized water, and then ultrasonically disperse for 30 minutes to obtain an antimony-doped tin oxide dispersion;

[0079] 2) Add 1.0 g of potassium permanganate and 0.8 g of ammonium oxalate solid to the antimony-doped tin oxide dispersion obtained in step 1), and then magnetically stir for 15 minutes at room temperature to obtain a mixed solution;

[0080] 3) Put the mixture obtained in step 2) into a hydrothermal reactor, and react for 12 hours at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com