Preparation method of catalytic cracking aid for increasing propylene yield

A catalytic cracking additive and propylene technology, which is applied in catalytic cracking, catalysts, hydrocarbon cracking and hydrocarbon production, etc. It can solve the problems of limited increase in propylene concentration, no attention to the secondary conversion of cracked products, and low propylene selectivity, so as to achieve a good society The effect of benefit and economic benefit, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

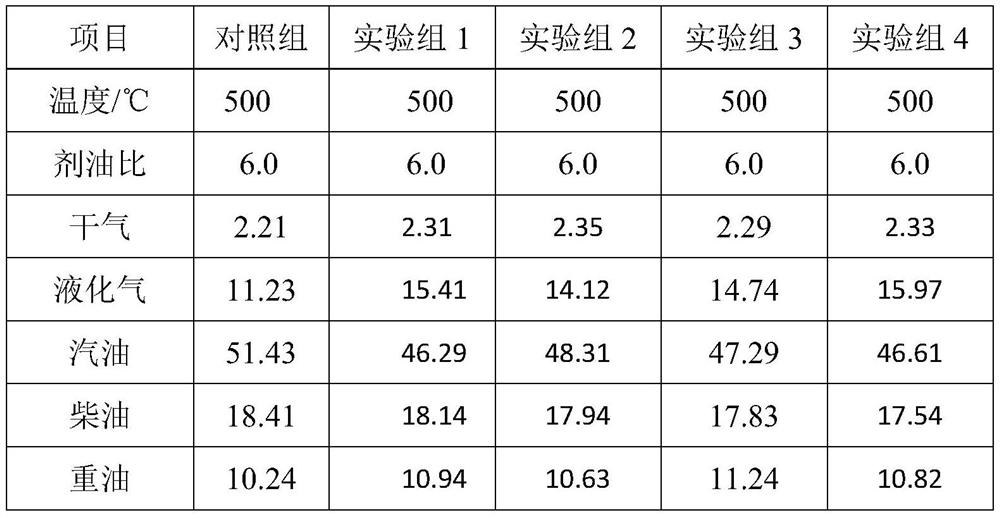

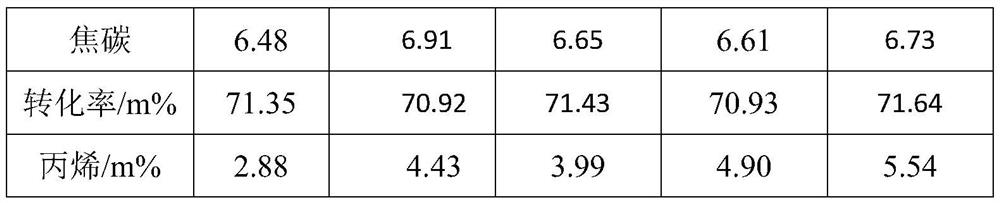

Examples

Embodiment 1

[0025] A preparation method for increasing the production of propylene catalytic cracking additive, comprising the steps of:

[0026] (1) Put 300g of kaolin, 700g of diatomaceous earth and 1700mL of deionized water into the reactor, add 10g of sodium silicate, stir for 2 hours at a speed of 200rpm, control the temperature of the water bath to 50°C, and mix the slurry evenly, Spray drying into microspheres, and calcining the microspheres at 900°C for 5 hours to obtain calcined microspheres;

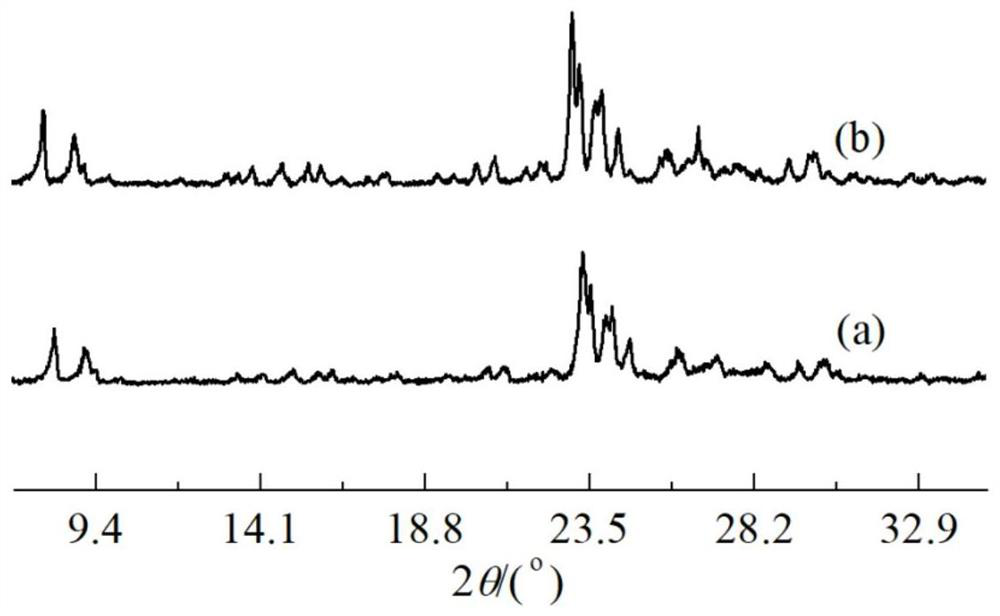

[0027] (2) 89g calcined microspheres, 5g white carbon black, 5g alumina, 403mL water glass, 42mL sodium hydroxide, 1g Y-type molecular sieve and 995mL deionized water are put into the crystallization reactor, and the final pH of the slurry is adjusted with sulfuric acid. To 11-12, hydrothermal crystallization at 150°C for 90 hours, after filtering to remove the mother liquor, the filter material was washed with water, filtered, and dried to obtain ZSM-5 molecular sieves; determined by X-ra...

Embodiment 2

[0032] A preparation method for increasing the production of propylene catalytic cracking additive, comprising the steps of:

[0033] (1) Put 200g of kaolin, 800g of diatomaceous earth and 1600mL of deionized water into the reactor, add 10g of sodium phosphate, stir at 250rpm for 1.5 hours, control the temperature of the water bath at 60°C, mix the slurry evenly, and spray Dried into microspheres, the microspheres were calcined at 1000°C for 1 hour to obtain calcined microspheres;

[0034] (2) 84g of calcined microspheres, 5g of white carbon black, 10g of alumina, 394mL of water glass, 39mL of sodium hydroxide, 1gX type molecular sieve and 1113mL of deionized water are dropped into the crystallization reactor, and the pH of the slurry terminal is adjusted to 11-12, hydrothermal crystallization at 160°C for 82 hours, after filtering to remove the mother liquor, the filter material was washed with water, filtered, and dried to obtain ZSM-5 molecular sieve; determined by X-ray di...

Embodiment 3

[0039] A preparation method for increasing the production of propylene catalytic cracking additive, comprising the steps of:

[0040] (1) Put 100g of kaolin, 900g of diatomaceous earth and 1500mL of deionized water into the reactor, add 10g of ammonium carbonate, stir at a speed of 300rpm for 1 hour, control the temperature of the water bath at 80°C, mix the slurry evenly, and spray Dried into microspheres, the microspheres were calcined at 950°C for 4 hours to obtain calcined microspheres;

[0041] (2) Put 100g of calcined microspheres, 1g of white carbon black, 1g of alumina, 450mL of water glass, 50mL of sodium hydroxide, 1g of ZSM-5 and 1200mL of deionized water into the crystallization reactor, and adjust the final pH of the slurry to 11-12, hydrothermal crystallization at 170°C for 68 hours, after filtering to remove the mother liquor, the filter material was washed with water, filtered, and dried to obtain ZSM-5 molecular sieve; X-ray diffraction determined that it cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com