Microalgal bio-based nitrogen-doped carbon material as well as preparation method and application thereof

A nitrogen-doped carbon, porous carbon material technology, applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problem of high price, hinder the promotion of carbon materials, adsorption effect and energy storage properties can not meet commercial Demand and other issues, to achieve the effect of low cost, easy artificial cultivation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] The present invention will be further described below in conjunction with specific embodiments, but these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0053]As mentioned above, the existing carbon materials themselves are used as adsorbents and supercapacitors. Although some of them have low cost, their adsorption effect and energy storage properties cannot meet commercial needs. Demand, but the high price hinders the promotion of carbon materials. In view of this, the present inventors conducted extensive research on carbon materials.

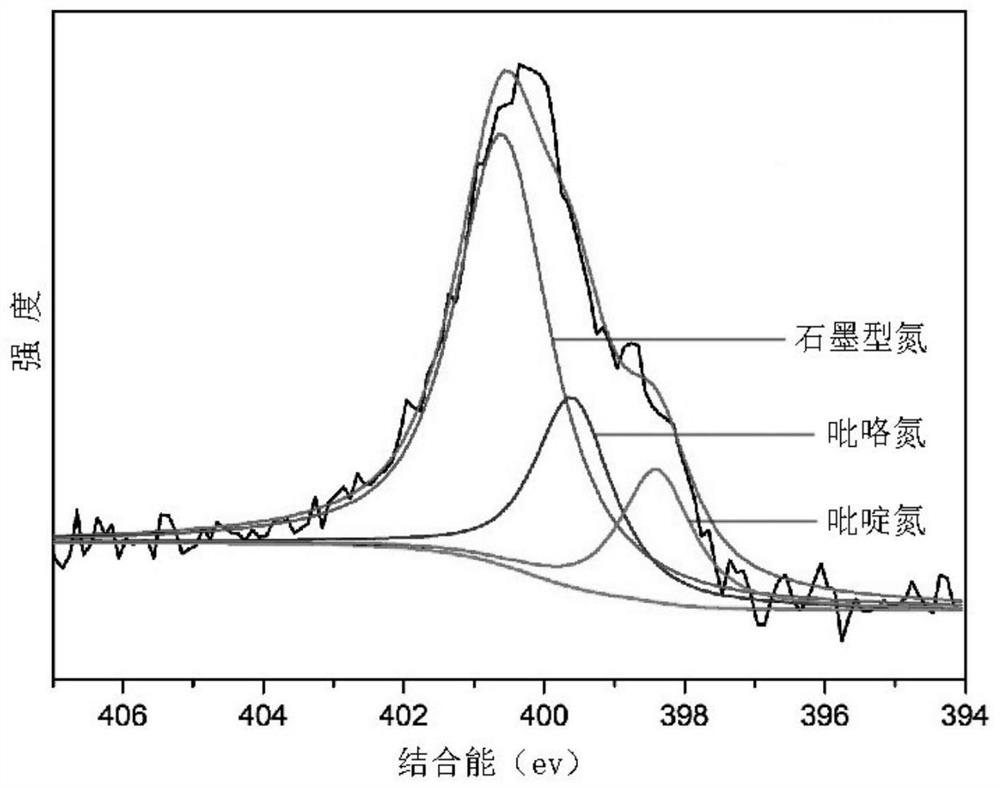

[0054] The present inventors found that compared with other biomass, microalgae has many advantages, such as microalgae has higher area yield, higher oil content, lower water content and is easy to grow on non-cultivated land. Microalgae are microorganisms that depend on photosynthesis for growth, and generally have three main components: lipids, proteins...

Embodiment 1

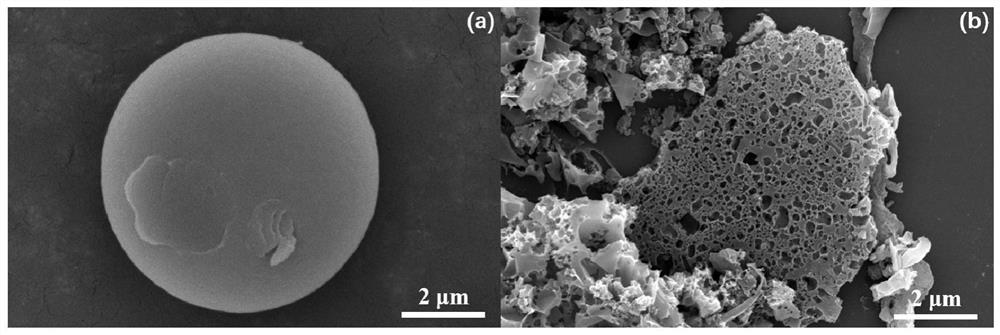

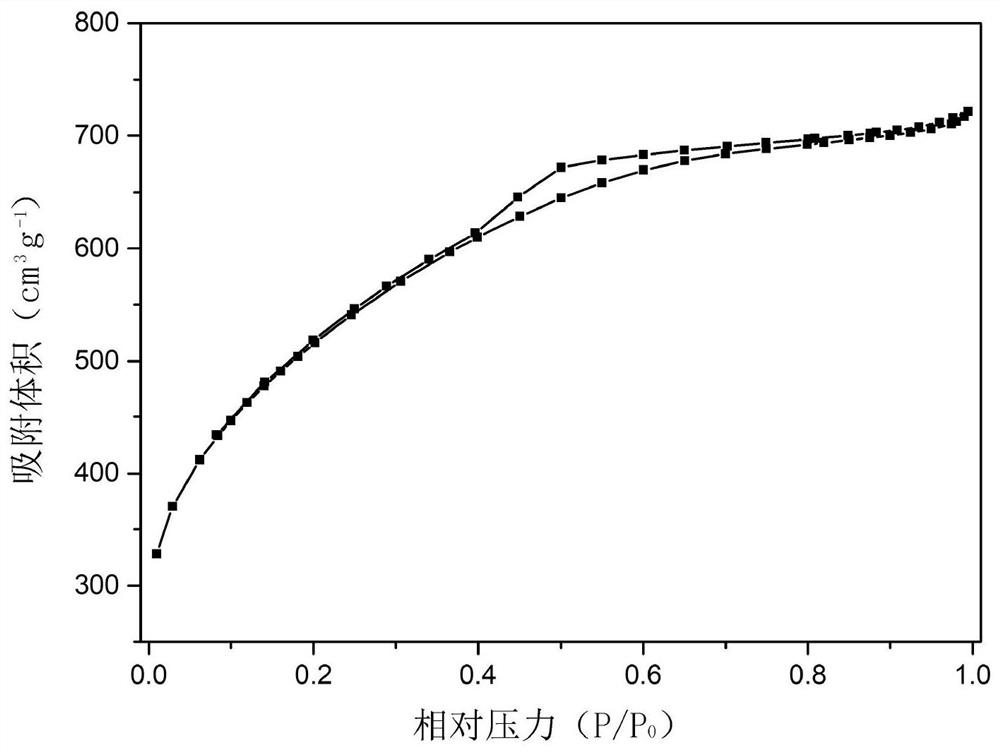

[0072] Weigh 3g of spirulina and glucose, add 70mL of deionized water to a 130mL polytetrafluoroethylene liner, and put it into a stainless steel reaction kettle. Put the stainless steel reactor into a homogeneous reactor, and react at 200°C for 24h. The obtained product was washed with deionized water and filtered to obtain a solid phase and a liquid phase respectively, and the liquid phase product was retained, and the solid phase product was put into an oven, and dried at 60° C. for more than 12 hours to obtain semi-coke. Weigh 1g of semi-coke and 4g of KOH solid, grind them thoroughly, put them into a tube furnace, and heat them under nitrogen atmosphere at 10°C min -1 The temperature was raised to 750°C and reacted for 1 hour to obtain a solid product. Put the solid product into a beaker, add excess hydrochloric acid, stir for more than 12 hours, filter the product, wash with a large amount of deionized water, and after the liquid is neutral after washing, put the carbon...

Embodiment 2

[0081] Weigh 5 mg of the carbon material prepared in Example 1, select acetylene black as the conductive agent, and weigh 1 mg. Add 1 mL of ethanol as a dispersant, and sonicate the suspension for 3 min. Add 50 μL of 5% Nafion solution to the suspension, sonicate for 2 hours to obtain a dispersed carbon material suspension, and add it dropwise to the nickel foam to obtain an electrode sheet, and put the prepared electrode in an oven at 60°C , dried for more than 2 hours and completely dried to obtain the finished electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com