Dioxopromethazine hydrochloride and preparation method thereof

A technology of dioxypromazine hydrochloride and dioxypromazine, which is applied in directions such as organic chemistry and chemical recovery, can solve the problems of long reaction time, increased production cost, loss of activity, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

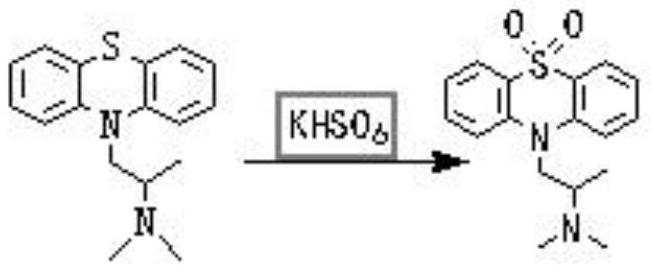

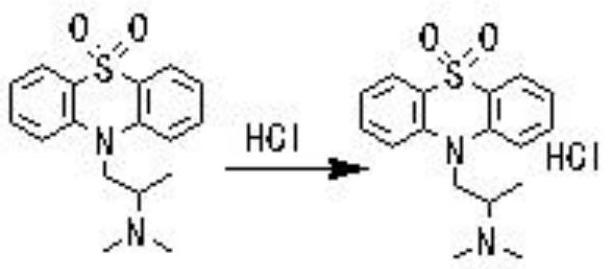

Image

Examples

Embodiment 1

[0024] A preparation method for dioxpromazine hydrochloride, comprising the following steps:

[0025] (1) Oxidation reaction: Cool solution A to 10°C, slowly add potassium persulfate solution, keep warm for 25 minutes after adding, heat to 30°C, keep warm for 5 hours, oxidize promethazine to dioxpromethazine, and obtain a solution B, Potassium persulfate solution was prepared by using 45.74g of potassium persulfate and 160mL of purified water.

[0026] Solution A was prepared as follows:

[0027] 1) join in the flask in the promethazine hydrochloride of 20g, add the purified water of 80ml and the hexanaphthene of 80ml, stir well, then under the condition of 30 ℃, add dropwise the aqueous solution of 15wt% sodium hydroxide, adjust the mixed solution The pH was 10, stirred for 20 min, allowed to stand for stratification, and the organic phase was separated, and the organic phase was washed twice with purified water;

[0028] 2) Place the washed organic phase (promethazine cycl...

Embodiment 2

[0038] A preparation method for dioxpromazine hydrochloride, comprising the following steps:

[0039] (1) Oxidation reaction: Cool solution A to 0°C, slowly add potassium hydrogen persulfate solution, keep warm for 15 minutes after adding, heat to 10°C, keep warm for 4 hours, oxidize promethazine to dioxpromethazine, and obtain a solution B, Potassium persulfate solution was prepared by using 40g of potassium persulfate and 160mL of purified water.

[0040] Solution A was prepared as follows:

[0041] 1) join in the flask in the promethazine hydrochloride of 15g, add the purified water of 70ml and the hexanaphthene of 70ml, stir well, then under 10 ℃ of conditions, add dropwise the aqueous solution of 15wt% sodium hydroxide, adjust the mixing solution The pH was 9, stirred for 10 minutes, allowed to stand and separated, and the organic phase was separated, and the organic phase was washed twice with purified water;

[0042] 2) Place the washed organic phase (promethazine cyc...

Embodiment 3

[0048] A preparation method for dioxpromazine hydrochloride, comprising the following steps:

[0049] (1) Oxidation reaction: Cool solution A to 5°C, slowly add potassium hydrogen persulfate solution, keep warm for 35 minutes after adding, heat to 20°C, keep warm for 4.5h, oxidize promethazine to dioxpromethazine, and obtain Solution B, potassium persulfate solution was prepared by using 45g of potassium persulfate and 160mL of purified water.

[0050] Solution A was prepared as follows:

[0051] 1) join in the flask in the promethazine hydrochloride of 25g, add the purified water of 80ml and the hexanaphthene of 80ml, stir, then dropwise the sodium hydroxide solution of 15wt% under the condition of 20 ℃, adjust the mixed solution The pH was 12, stirred for 30 minutes, allowed to stand for stratification, and the organic phase was separated, and the organic phase was washed twice with purified water;

[0052] 2) Place the washed organic phase (promethazine cyclohexane soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com