Rubidium-doped high-rate lithium battery positive electrode material and preparation method thereof

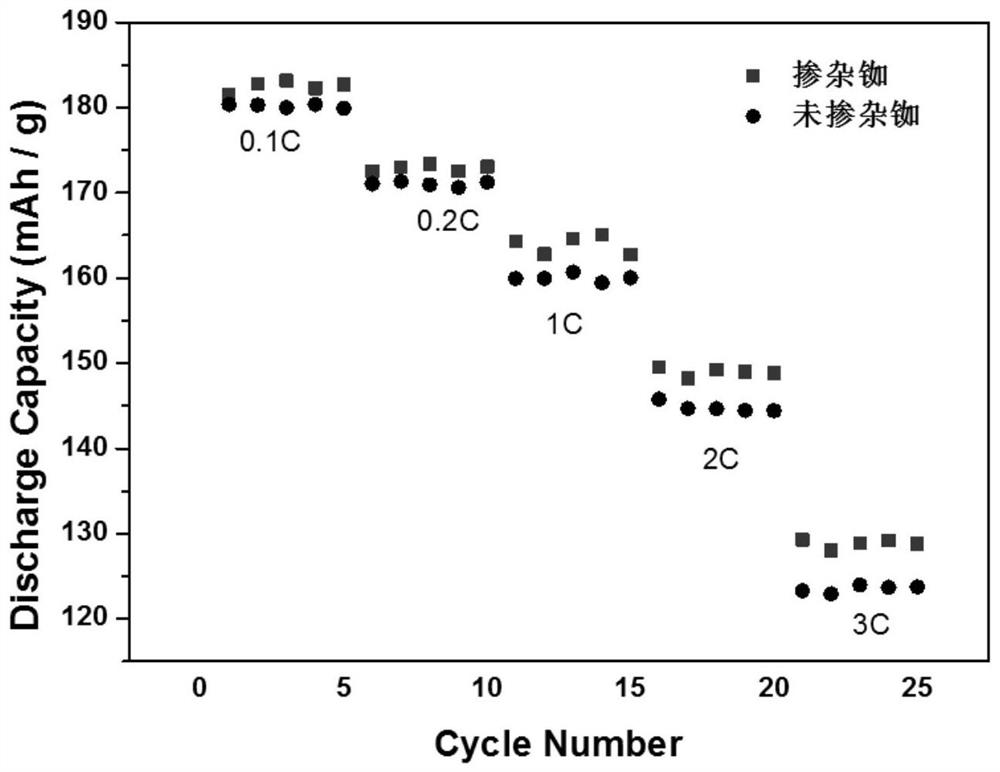

A cathode material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low charging rate of lithium batteries, and achieve the effect of promoting lithium ion conduction, improving charging rate performance and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a rubidium-doped high-rate lithium battery positive electrode material, the specific steps are as follows:

[0025] Step 1: Uniformly mix 50 parts of lithium cobaltate, 1 part of rubidium carbonate, and 0.5 part of cesium carbonate according to the mass parts, and place them in a tube furnace for calcination at a high temperature of 600°C for 10 hours to obtain a precursor material;

[0026] Step 2: Anneal the precursor material after high-temperature calcination in step 1, and then mix 10 parts of 2wt% polyamide solution (using N-methylpyrrolidone as solvent), 3 parts of conductive Nano-carbon material (the consumption of carbon nanotube and conductive carbon black is respectively 0.02wt%, 0.6wt% of positive electrode active material lithium cobalt oxide quality; Wherein the diameter of carbon nanotube is about 2nm, and length is about 2um, and the amount of conductive carbon black Specific surface at 50m 2 / g, the particle size is about 10nm), ...

Embodiment 2

[0032] A method for preparing a rubidium-doped high-rate lithium battery positive electrode material, the specific steps are as follows:

[0033] Step 1: Mix 80 parts of lithium manganate and lithium nickel cobalt aluminate mixture (mass ratio 1:1), 5 parts of rubidium hydroxide, and 2 parts of cesium bicarbonate according to the mass parts, and place them in a tube furnace Calcining at 1000° C. for 5 hours to obtain the precursor material.

[0034] Step 2: Anneal the precursor material after high-temperature calcination in step 1, and then mix 20 parts of 5 wt% polyvinylpyrrolidone solution (using N-methylpyrrolidone as the solvent), 5 parts Conductive nano-carbon material (the consumption of carbon nanotube and conductive carbon black is respectively 0.04wt% and 1wt% of the total mass of positive electrode active material lithium manganate and nickel-cobalt-aluminate lithium mixture; wherein the diameter of carbon nanotube is about 7nm, length It is about 15um, and the spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com