Preparation method and application of intermediate for preparing fluocalcitol

A technology for intermediates, calcidol, applied in the field of preparation of intermediates, can solve the problems of high cost, low safety, expensive raw materials, etc., and achieve the effects of simplifying reaction steps, high yield and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

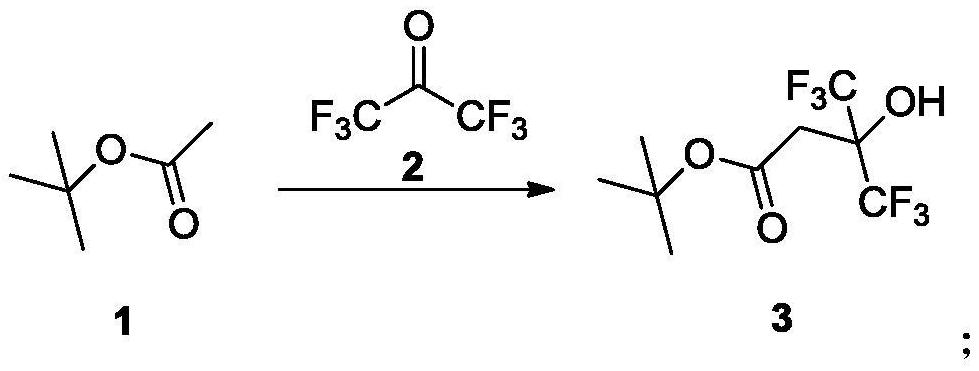

[0061] Embodiment 1: the preparation of compound 3

[0062] Add compound 1 (30.0g, 258.4mmol, 0.861mol / L) and n-hexane (300ml) into a 2000ml three-necked flask, cool the reaction down to -60°C to -65°C, dropwise add lithium diisopropylamide (258.4ml, 258.4 mmol), keep the temperature and react for 30min, slowly add the saturated n-hexane solution (260.0ml) of compound 2 dropwise, keep the temperature and react for 1h, quench the reaction with saturated aqueous ammonium chloride solution, separate the organic phase, dry and concentrate to obtain 36.4g compound 3. The yield is 50.0%. Preparation of saturated n-hexane solution of hexafluoroacetone: drop the trihydrate of hexafluoroacetone into concentrated sulfuric acid, and absorb the generated gas with n-hexane (-20°C to -40°C) until saturated.

Embodiment 2

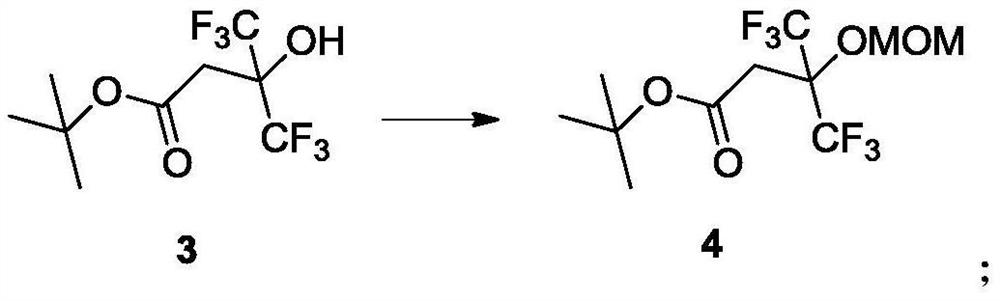

[0063] Embodiment 2: the preparation of compound 4

[0064] Under argon protection, compound 3 (35.0g, 124.1mmol) was added to a 500mL three-necked flask, then dichloromethane (300.0ml) was added, diisopropylethylamine (48.1g, 372.3mmol) was added, and the temperature was lowered to 0 Add methoxychloromethane (19.8g, 248.2mmol) at ℃, naturally warm up to room temperature, stir for 36 hours, add the reaction solution into aqueous sodium bicarbonate solution, extract with ethyl acetate, dry and concentrate to obtain the crude product, which is subjected to silica gel column chromatography 28.3 g of compound 4 was obtained, with a yield of 70.0%.

Embodiment 3

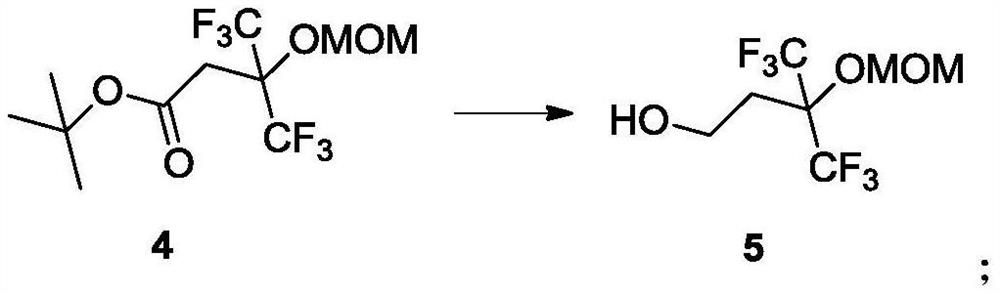

[0065] Embodiment 3: the preparation of compound 5

[0066] Compound 4 (28.0g, 85.8mmol) was added to a 500mL three-neck flask, tetrahydrofuran (280.0ml) was added, the temperature was lowered to -5°C to 0°C, and lithium aluminum hydride (3.3g, 85.8mmol) was added in batches while maintaining the temperature. The mixture was reacted at high temperature for 1 hour, quenched by adding aqueous sodium hydroxide solution, extracted with ethyl acetate, dried and concentrated to obtain a crude product, which was subjected to silica gel column chromatography to obtain 15.8 g of compound 5 with a yield of 72.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com