Mesoporous alumina ceramic coated diaphragm and preparation method thereof

A mesoporous alumina and ceramic coating technology, which is applied to electrochemical generators, structural parts, electrical components, etc., can solve the problems of insufficient liquid absorption and liquid retention capacity of alumina ceramic diaphragms, achieve high pore capacity, improve Effects of improving electrical performance, liquid absorption capacity, and liquid retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

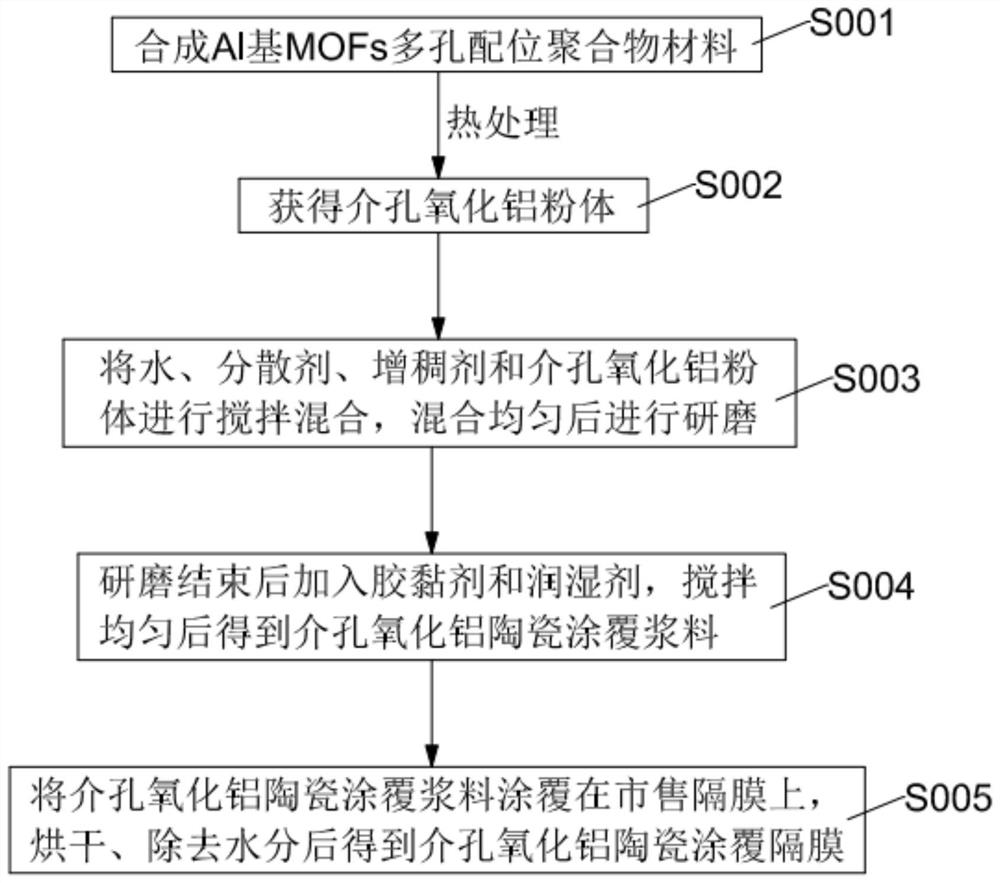

[0040] Further, in order to obtain the mesoporous alumina ceramic coated diaphragm, the present invention provides a method for preparing the above diaphragm, comprising the following preparation steps:

[0041] S001, synthesis of NH 2 -MIL-53(Al), NH 2 - At least one of MIL-101(Al), Al-PCP;

[0042] S002, performing heat treatment on the Al-based MOFs material obtained in step S001 to obtain mesoporous alumina powder;

[0043] S003, stirring and mixing water, dispersant, thickener and the mesoporous alumina powder obtained in step S002, and grinding after mixing evenly;

[0044] S004, adding an adhesive and a wetting agent to the grinding material obtained in step S003, and stirring evenly to obtain a mesoporous alumina ceramic coating slurry;

[0045] S005. Coating the mesoporous alumina ceramic coating slurry obtained in step S004 on one or both sides of a commercially available diaphragm through a coating machine, drying and removing moisture to obtain a mesoporous alumin...

Embodiment 1

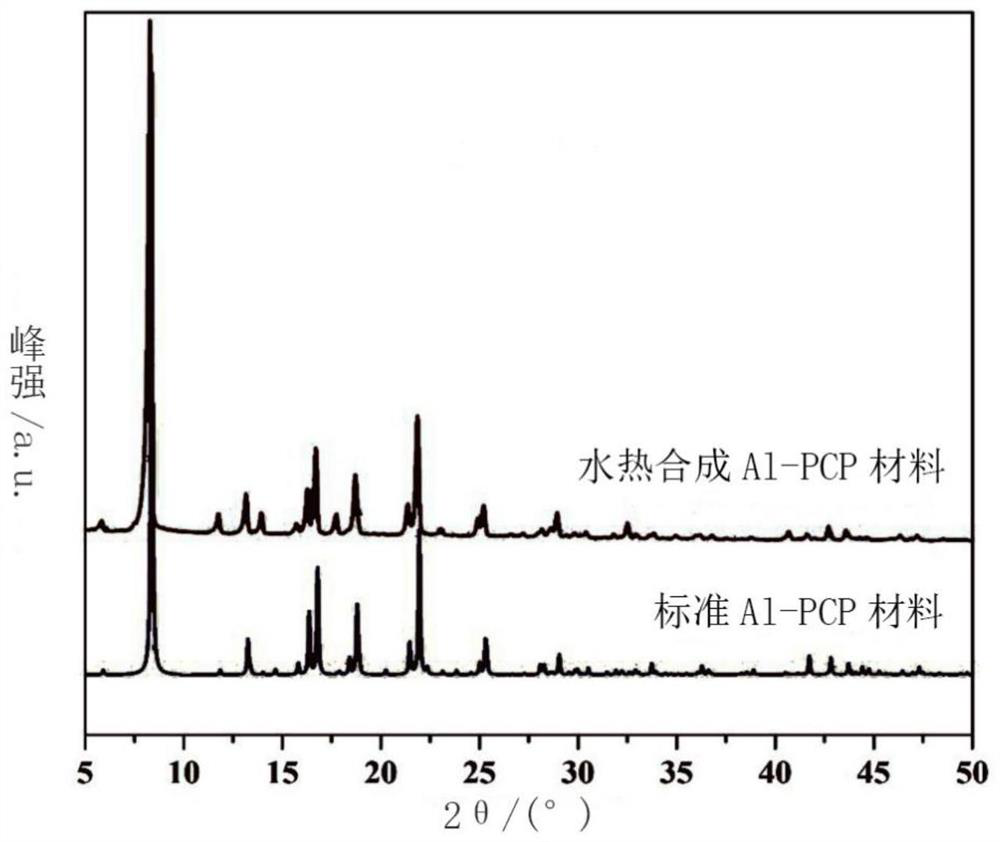

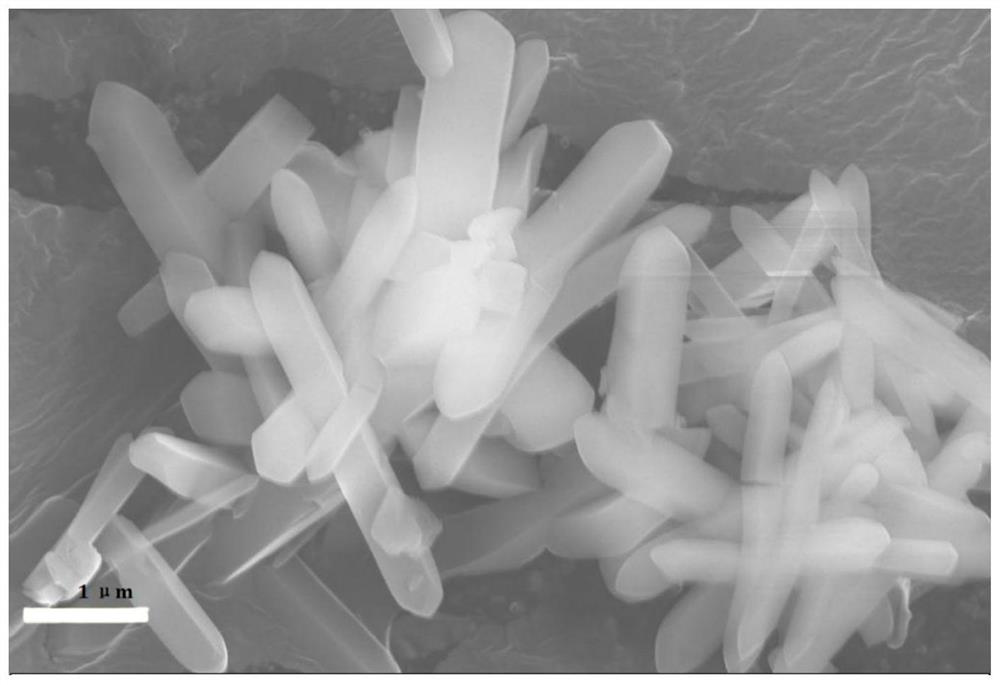

[0065] (1) Add 1.5g of aluminum nitrate nonahydrate, 0.432g of 1,4-naphthalene dicarboxylic acid and 40mL of deionized water into a hydrothermal reaction kettle with 100mL of water and stir at room temperature for 1h. After mixing evenly, seal the hydrothermal reaction kettle and Place it in a blast drying oven, keep it warm at 180°C for 24 hours, and synthesize Al-PCP material by hydrothermal reaction;

[0066] (2) After the reaction time was reached, the hydrothermal reaction kettle was naturally cooled, the hydrothermal synthesis product was suction-filtered, washed with deionized water for three times, and then dried under vacuum at 150°C for 12 hours to obtain a light yellow Al-PCP powder sample;

[0067] (3) Carry out heat treatment on the obtained Al-PCP powder sample, calcining it under nitrogen atmosphere, the heating rate is 5°C / min, keep it warm for 2 hours after reaching 600°C, and cool naturally after the heat preservation is over to obtain mesoporous alumina powde...

Embodiment 2

[0073] (1) Add 1.5g of aluminum nitrate nonahydrate, 0.432g of 1,4-naphthalene dicarboxylic acid and 40mL of deionized water into a hydrothermal reaction kettle with 100mL of water and stir at room temperature for 1h. After mixing evenly, seal the hydrothermal reaction kettle and Place it in a blast drying oven, keep it warm at 180°C for 24 hours, and synthesize Al-PCP material by hydrothermal reaction;

[0074] (2) After the reaction time was reached, the hydrothermal reaction kettle was naturally cooled, the hydrothermal synthesis product was suction-filtered, washed with deionized water for three times, and then dried under vacuum at 150°C for 12 hours to obtain a light yellow Al-PCP powder sample;

[0075] (3) Carry out heat treatment on the obtained Al-PCP powder sample, calcining in the air atmosphere, the heating rate is 5 ° C / min, after reaching 700 ° C, heat preservation for 2 hours, after the heat preservation is completed, naturally cool to obtain the mesoporous al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com