Composite modified diaphragm for lithium-sulfur battery and preparation method of composite modified diaphragm

A composite modification, lithium-sulfur battery technology, used in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of single function, damage, loss of active materials, etc. performance, solve the shuttle effect, and promote the effect of efficient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

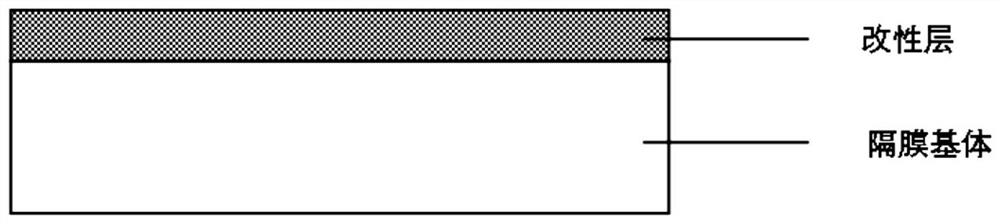

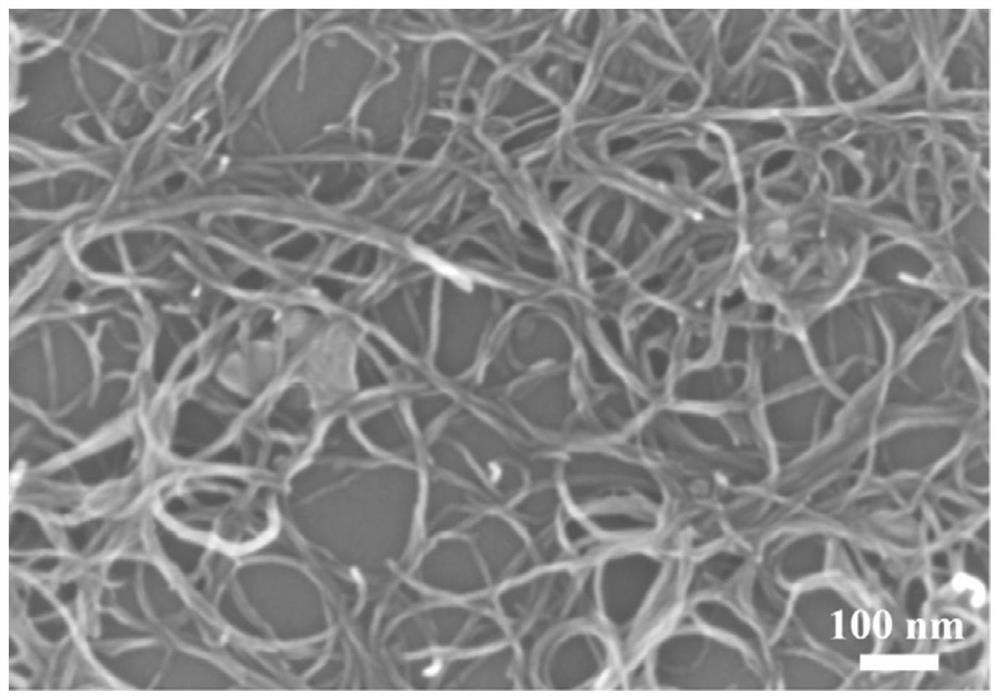

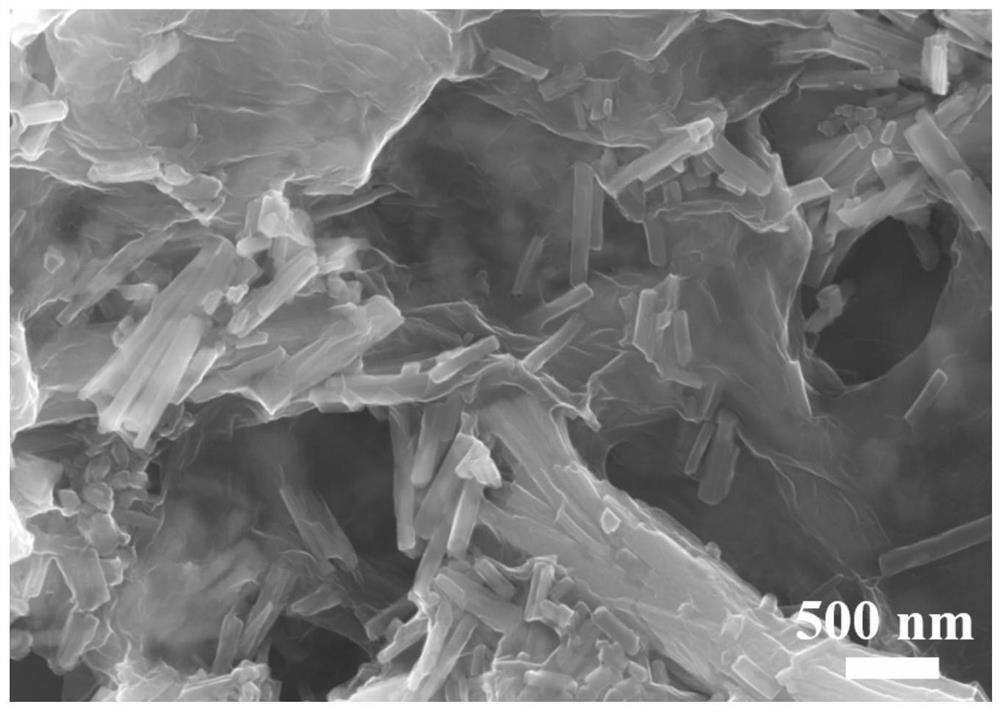

[0037] This embodiment provides a composite modified diaphragm for lithium-sulfur batteries, the modified diaphragm includes two parts: a diaphragm base and a modified layer laid on one side of the diaphragm base. The separator substrate is a common commercial battery separator substrate, and the modified layer includes 2 to 4 layers of CNTs and 1 to 3 layers of CeO 2-x / C / rGO layer (CeO 2-x / C / rGO layer is one layer less than CNTs layer), CNTs layer and CeO 2-x / C / rGO layers are laid alternately on one side of the membrane matrix and the CNTs layer is in contact with the membrane matrix.

[0038] The diaphragm substrate has a planar structure and a large number of through holes, which can be polypropylene (PP) porous membrane, polyethylene (PE) porous membrane, polyethylene / polypropylene composite porous membrane, polyimide diaphragm, polyethylene terephthalate One of the diester-based non-woven separators. In this example, the separator substrate was a commercially availa...

Embodiment 2

[0061] The preparation method of this embodiment is the same as that of Example 1, except that step (1) is not carried out, and other implementation conditions remain unchanged.

[0062]Compared with Example 1, the electrochemical properties of the lithium-sulfur battery assembled with the modified separator prepared in this example, such as capacity, rate and cycle stability, are all lower compared with Example 1: initial discharge capacity at 0.5C After 200 cycles of charge and discharge, the specific capacity drops to 726mAh / g, and the capacity retention rate is 68.9%. The discharge capacity of the first cycle of 1C cycle charge and discharge is 1055mAh / g, and the discharge capacity of the battery after 500 cycles of long cycle is 563mAh / g, the capacity retention rate is 53.4%; in addition, the rate performance is also reduced.

Embodiment 3

[0064] The preparation method of this embodiment is the same as that of Example 1, except that in step (4), the CNTs layer and CeO are alternately suction-filtered on the surface of the commercial battery PP separator (Celgard2500) substrate. 2-x The layers of / C / rGO layers are 4 layers and 3 layers respectively, CNTs and CeO 2-x The mass ratio of / C / rGO was 2:1, the vacuum drying temperature was 50 °C, and other implementation conditions were kept unchanged.

[0065] Compared with Example 1, the area loading of the surface modification layer of the modified diaphragm prepared in this example is 0.25 mg / cm 2 , with a thickness of 9 μm. Compared with Example 1, the electrochemical properties of the lithium-sulfur battery assembled with the modified diaphragm prepared in this example, such as capacity, rate and cycle stability, are reduced: the initial discharge capacity at 0.5C is 1051mAh / g, 200 cycles After charging and discharging, the specific capacity drops to 738mAh / g, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com