A kind of high temperature resistant elastic graphene airgel and preparation method thereof

An elastic graphite, high temperature resistant technology, applied in aerogel preparation, chemical instruments and methods, colloidal chemistry, etc., can solve the problems of destroying graphene aerogel structure, elastic graphene aerogel limitation, etc., and achieve slow oxidation , the effect of excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a kind of preparation method of high temperature resistant elastic graphene airgel in first aspect, described method comprises the steps:

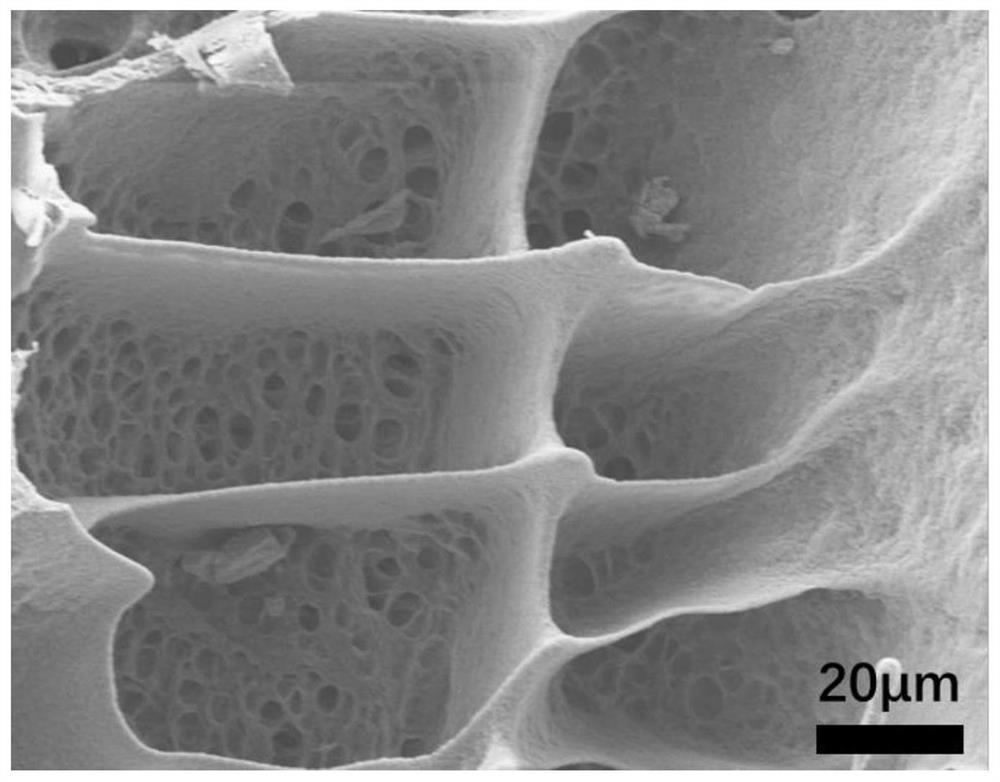

[0035](1) graphene oxide solution (such as graphene oxide aqueous solution), reducing agent, surfactant and silica sol are stirred and mixed uniformly to obtain precursor foam (also referred to as graphene oxide precursor foam); in the present invention, For example, first add the purified graphene oxide aqueous solution in a beaker, then add reducing agent, surfactant and silica sol in turn, and use a stirring paddle with a suitable diameter to stir evenly to obtain a graphene oxide precursor foam for subsequent use; in the present invention , it is preferred that the graphene oxide contained in the graphene oxide aqueous solution is all single-layered, and the purchased graphene oxide is subjected to high-speed centrifugal purification before use to make the sheet diameter distribution as narrow as po...

Embodiment 1

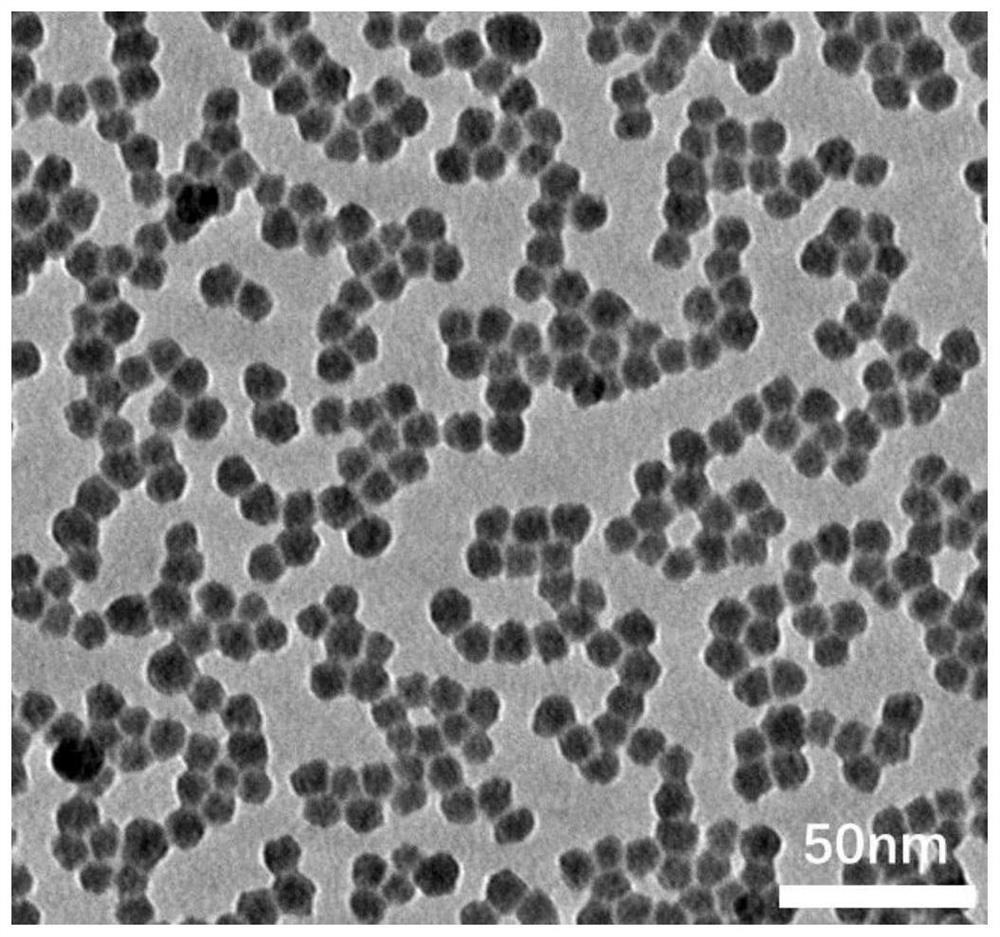

[0070] ①Add 15mL of single-layer graphene oxide aqueous solution (wherein the diameter of the graphene sheet is 6±2μm and the concentration is 10mg / mL) after centrifugation and purification into a 150mL beaker, then add 0.6g of sodium ascorbate, 0.15g of surfactant benzene Ethylene maleic anhydride resin SMA and 1 mL of silica sol with lysine surface modification and excellent monodispersity (containing silica nanoparticles with a particle size of 8 ± 1 nm and a mass fraction of 25%), and using a diameter of 2.5 cm The stirring paddle was stirred at a stirring speed of 1600rpm for 5min to stir the above-mentioned mixed solution evenly to obtain about 40mL graphene oxide precursor foam (bubble rate 2.5) for use.

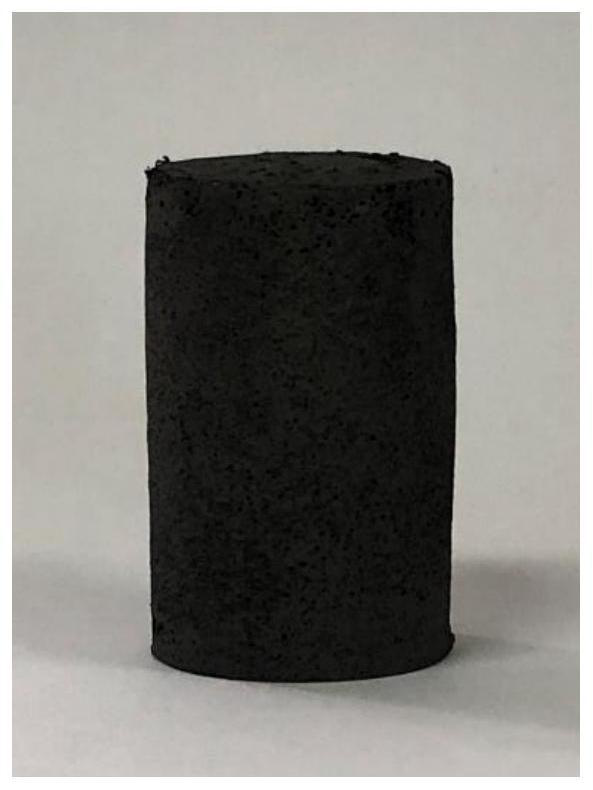

[0071] ②Pour the above-mentioned graphene oxide precursor foam into the tetrafluoroethylene liner of a metal reactor with a height of 3cm and a diameter of 1.5cm, tighten the reactor, and put the reactor into a blast furnace with a temperature of 70°C. Reaction in the...

Embodiment 2

[0077] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0078] In step ①, add 10 mL of single-layer graphene oxide aqueous solution (wherein the diameter of the graphene sheet is 6±2 μm and the concentration is 10 mg / mL) after centrifugal purification into a 150 mL beaker, then add 0.1 g sodium ascorbate, 0.01 g Surfactant styrene maleic anhydride resin SMA and 1mL surface modified with lysine, silica sol with excellent monodispersity (the particle size of silica nanoparticles contained is 8 ± 1nm, mass fraction is 25%), and use A stirring blade with a diameter of 2.5 cm was stirred at a stirring speed of 1600 rpm for 5 minutes to stir the above mixed solution evenly to obtain a graphene oxide precursor foam for use.

[0079] After the high-temperature resistant elastic graphene airgel prepared in this example was subjected to a high-temperature assessment in an oven at 800°C and in an air atmosphere for 10 minutes, the shape of the airgel did not chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com