Purification process of acetal phospholipid

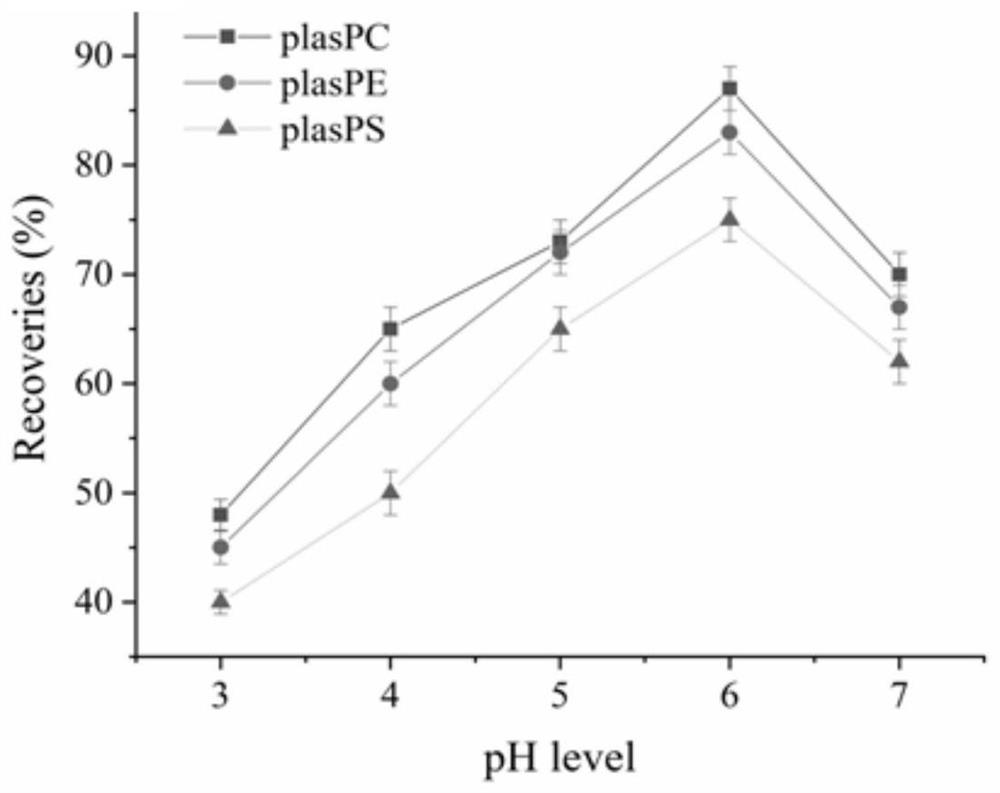

A plasmalogen and process technology, which is applied in the field of plasmalogen purification process, can solve the problems of qualitative and quantitative difficulties of plasmalogen, and achieve the effect of increasing extraction capacity, increasing recovery rate, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

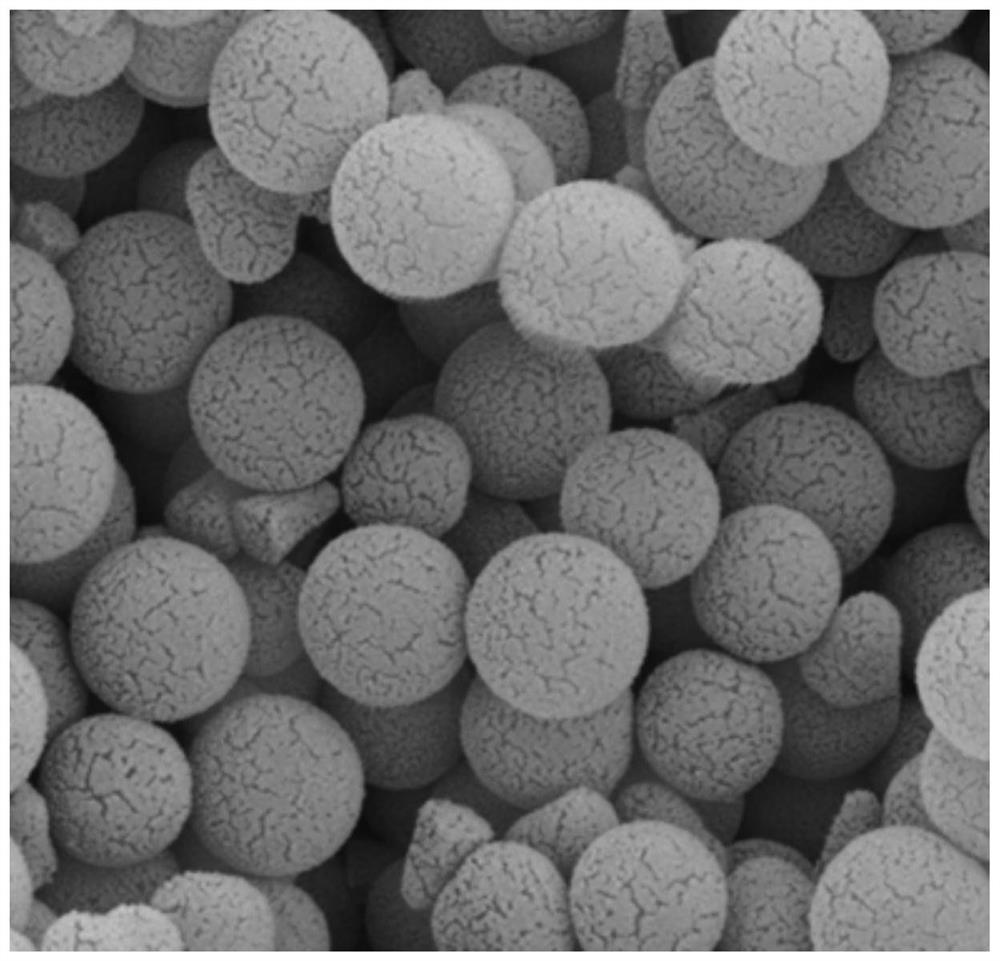

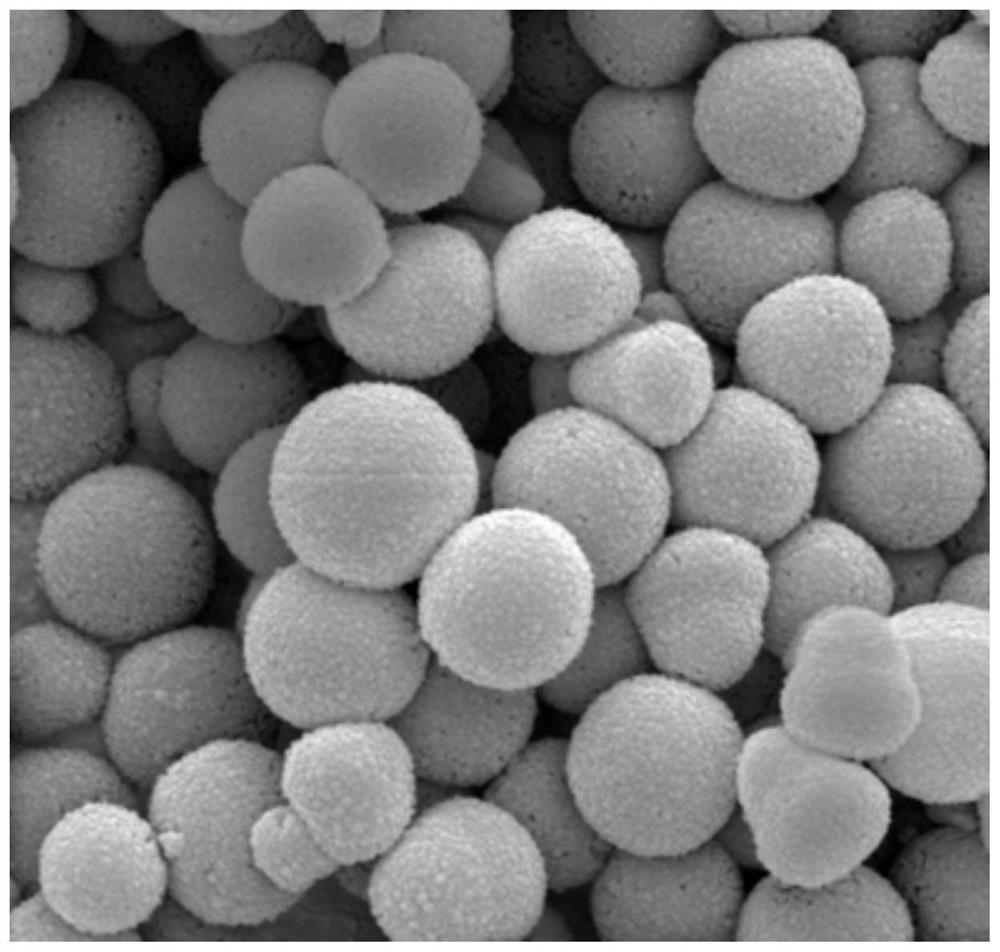

[0098] Example 1. A kind of purification process of plasmalogen, comprises the following steps,

[0099] a1. Dissolve 10mmol urea and 2.86mmol of CPB (i.e. cetylpyridinium bromide) in every 30mL of water to obtain the A1 product.

[0100] a2. Add 30mL of cyclohexane and 0.94mL of 2-propanol to the A1 product to obtain the A2 product.

[0101] a3. Add 3 mL of tetraethyl orthosilicate to product A2 to obtain product A3.

[0102] a4. Stir product A3 for 30 minutes to obtain product A4.

[0103] A5 and A4 products were heated to 70°C and stirred for 20 hours to obtain A5 products.

[0104] A6 and A5 products were centrifuged for 10 minutes to obtain A6 products.

[0105] A7, A6 product are washed with acetone, deionized water and ethanol successively to obtain A7 product,

[0106] a8, A7 products were vacuum-dried for 12 hours to obtain A8 products,

[0107] A9 and A8 products were calcined at 450-550°C for 4 hours to obtain KCC-1, namely A9 products;

[0108] Dissolve 2.2g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com