Preparation method of anatase type nano titanium dioxide microspheres

A nano-titanium dioxide, anatase-type technology, applied in the field of photocatalytic materials, can solve problems such as pollution and corrosive environment, and achieve the effects of avoiding environmental pollution, avoiding equipment corrosion, and having good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

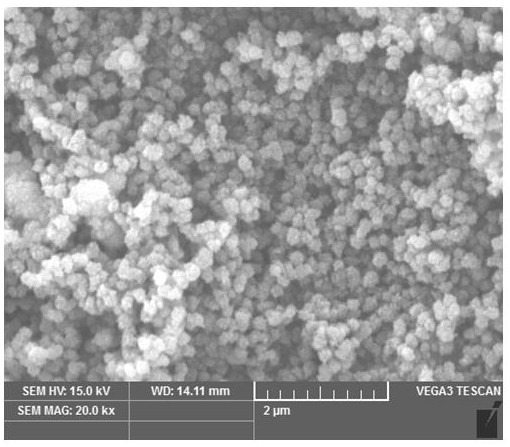

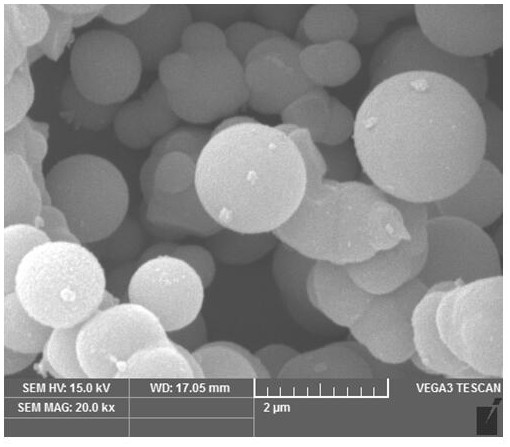

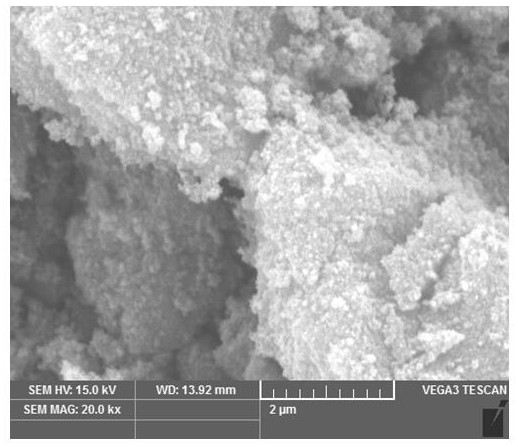

Image

Examples

Embodiment 1

[0030] (1) Pour 1mL of diethylenetriamine into a beaker, and under an ultrasonic field (ultrasonic power 300W), add 280mL of isopropanol dropwise into the diethylenetriamine at a rate of 10mL / min, and continue to Ultrasonic dispersion for 10 minutes to obtain solution A;

[0031] (2) Pour 10mL of isopropyl titanate into a beaker, and under an ultrasonic field (ultrasonic power 300W), add the solution A obtained in step (1) into the beaker dropwise at a rate of 5mL / min, and the addition is completed Then continue ultrasonic dispersion for 0.5h to obtain solution B;

[0032] (3) Solution B is moved into an autoclave with a polytetrafluoroethylene liner, and the filling degree of the autoclave is 80%, and then the autoclave is put into a 180° C. electronic constant temperature blast drying oven to react for 24 hours, Then cool to room temperature;

[0033] (4) The supernatant in the autoclave is removed, and the precipitate is collected by centrifugation;

[0034] (5) The prec...

Embodiment 2

[0038] (1) Pour 0.33mL of diethylenetriamine into a beaker, and under an ultrasonic field (ultrasonic power 300W), add 280mL of isopropanol dropwise into diethylenetriamine at a rate of 10mL / min. Continue ultrasonic dispersion for 10 minutes to obtain solution A;

[0039] (2) Pour 10mL of isopropyl titanate into a beaker, and under an ultrasonic field (ultrasonic power 300W), add the solution A obtained in step (1) into the beaker dropwise at a rate of 10mL / min, and the addition is completed Then continue ultrasonic dispersion for 0.5h to obtain solution B;

[0040] (3) Solution B is moved into an autoclave with a polytetrafluoroethylene liner, and the filling degree of the autoclave is 80%, and then the autoclave is put into a 180° C. electronic constant temperature blast drying oven to react for 24 hours, Then cool to room temperature;

[0041] (4) The supernatant in the autoclave is removed, and the precipitate is collected by centrifugation;

[0042] (5) The precipitate...

Embodiment 3

[0046] (1) Pour 0.33mL of diethylenetriamine into a beaker, and under an ultrasonic field (ultrasonic power 300W), add 280mL of isopropanol dropwise into diethylenetriamine at a rate of 10mL / min. Continue ultrasonic dispersion for 10 minutes to obtain solution A;

[0047] (2) Pour 10 mL of isopropyl titanate into a beaker, place it on a magnetic stirrer, add the solution A obtained in step (1) into the beaker dropwise at a rate of 5 mL / min, and continue magnetic stirring after the addition is complete. Stir for 0.5h to obtain solution B;

[0048](3) Solution B is moved into an autoclave with a polytetrafluoroethylene liner, and the filling degree of the autoclave is 80%, and then the autoclave is put into a 180° C. electronic constant temperature blast drying oven to react for 24 hours, Then cool to room temperature;

[0049] (4) The supernatant in the autoclave is removed, and the precipitate is collected by centrifugation;

[0050] (5) The precipitate obtained in step (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com