Inorganic silicon modified soap-free acrylic emulsion and preparation method thereof

A technology of acrylic emulsion and inorganic silicon, applied in the direction of coating, etc., can solve the problems of unstable scratch resistance, poor water resistance, etc., and achieve the effect of low cost, strong storage stability, and good thickening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

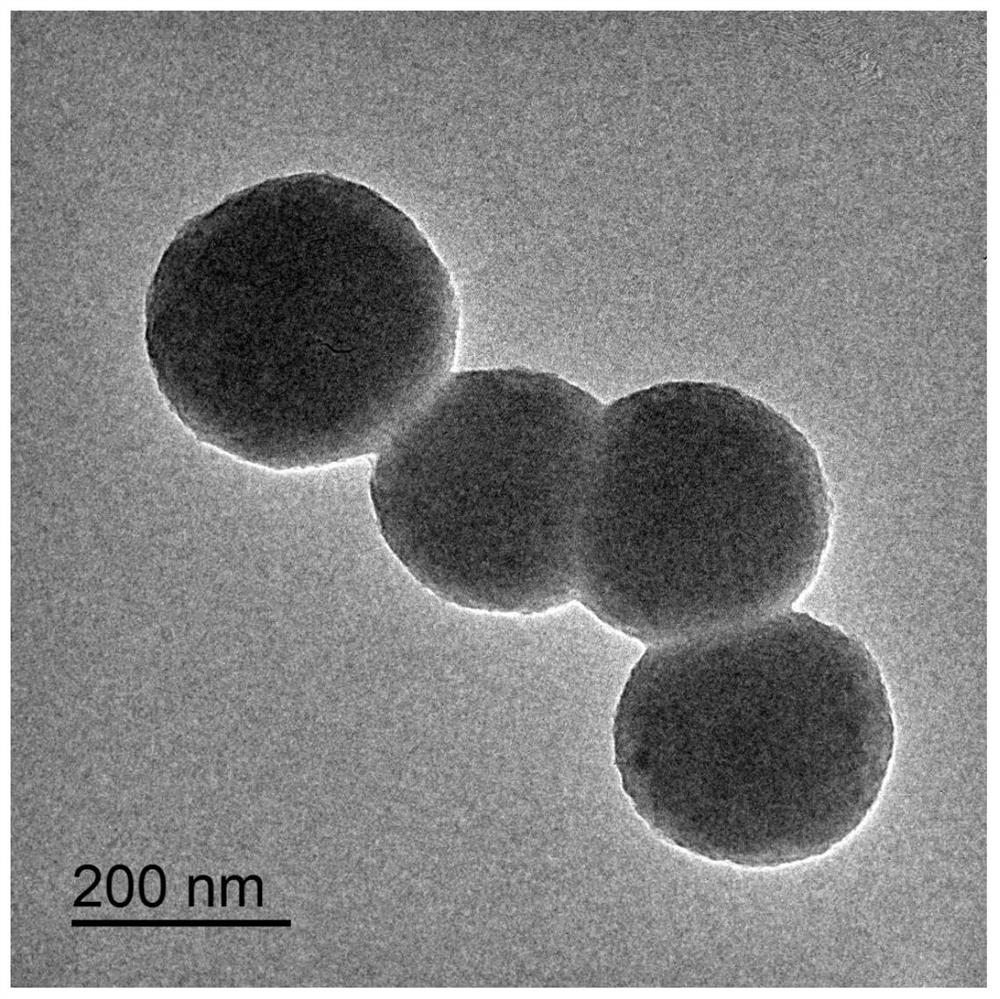

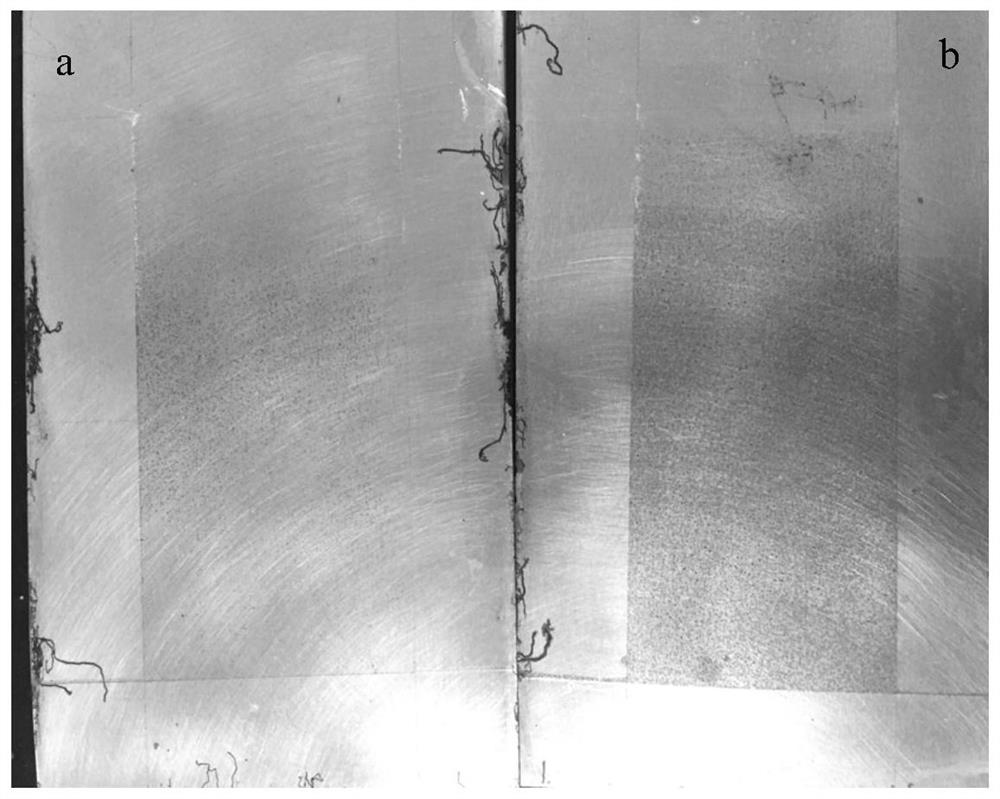

Image

Examples

Embodiment 1

[0036] In this embodiment, the preparation method of inorganic silicon modified soap-free acrylic acid emulsion is as follows:

[0037] (1) Add 10g of ethylene glycol butyl ether to a four-necked flask with a stirring and reflux device, and then raise the temperature to 150°C. Prepare 25.86g of acrylamide-methylpropanesulfonic acid, 10.72g of hydroxyethyl methacrylate, 21g of styrene, 20.28g of methyl methacrylate, 18g of butyl acrylate, 20g of dimethylformamide and 4.2g of benzoyl peroxide were mixed and stirred evenly to obtain a mixed solution A; after the temperature rose to 150°C , evenly drop the mixed solution A into the four-necked flask, drop it in about 5 hours, keep it warm for 2 hours and cool it down to 80°C, and discharge it for later use;

[0038] (2) Add 2 g of inorganic fumed silica to the spare material obtained in step (1) at room temperature, stir evenly to obtain a mixed solution B, and set aside;

[0039](3) Add 5.8g of mixed solution B prepared in step ...

Embodiment 2

[0043] In this embodiment, the preparation method of inorganic silicon modified soap-free acrylic acid emulsion is as follows:

[0044] (1) Add 20g of ethylene glycol butyl ether to a four-necked flask with a stirring and reflux device and then heat up to 150°C. In advance, 15.86g of acrylamide-methylpropanesulfonic acid, 15.72g of hydroxyethyl methacrylate, 21g of styrene, 23.28g of methyl methacrylate, 20g of butyl acrylate, 10g of dimethylformamide and 4.2g of benzoyl peroxide were mixed and stirred evenly to obtain a mixed solution A; after the temperature rose to 150°C , evenly drop the mixed solution A into the four-necked flask, drop it in about 5 hours, keep it warm for 2 hours and cool it down to 80°C, and discharge it for later use;

[0045] (2) Add 2 g of fumed inorganic phase silica to the spare material obtained in step (1) at room temperature, stir evenly to obtain a mixed solution B, and set aside;

[0046] (3) Add 5.8g of mixed solution B prepared in step (2),...

Embodiment 3

[0050] In this embodiment, the preparation method of inorganic silicon modified soap-free acrylic acid emulsion is as follows:

[0051] (1) Add 10g of ethylene glycol butyl ether to a four-necked flask with a stirring and reflux device, and then raise the temperature to 150°C. Prepare 25.86g of acrylamide-methylpropanesulfonic acid, 10.72g of hydroxyethyl methacrylate, 21g of styrene, 20.28g of methyl methacrylate, 18g of butyl acrylate, 20g of dimethylformamide and 4.2g of benzoyl peroxide were mixed and stirred evenly to obtain a mixed solution A; after the temperature rose to 150°C , evenly drop the mixed solution A into the four-necked flask, drop it in about 5 hours, keep it warm for 2 hours and cool it down to 80°C, and discharge it for later use;

[0052] (2) Add 2 g of inorganic fumed silica to the spare material obtained in step (1) at room temperature, stir evenly to obtain a mixed solution B, and set aside;

[0053] (3) Add 5.8g of mixed solution B prepared in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com