Three-dimensional carbon nanophase composite reinforced aluminum-based material and preparation method thereof

A composite reinforcement, aluminum-based material technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor compatibility, difficult to obtain synergistic reinforcement effect, etc., to achieve low cost, good generalizability, improved strength and plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

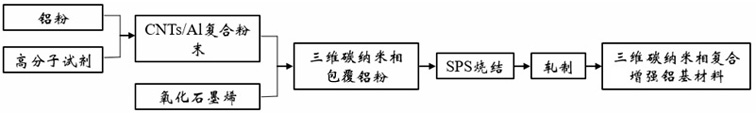

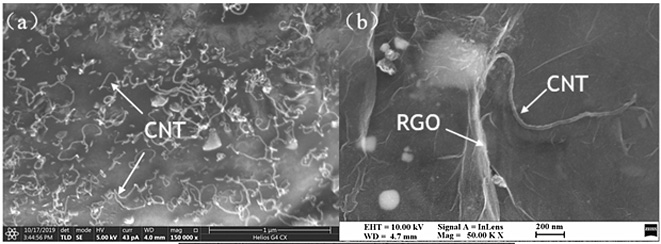

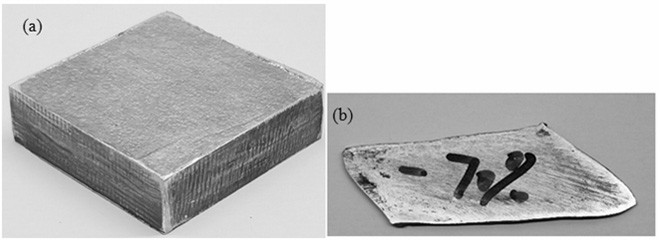

[0027] The preparation of a three-dimensional carbon nanophase composite reinforced aluminum-based material comprises the following steps:

[0028] 1) Dissolve 1g of DGEBA and 0.5g of nickel nitrate hexahydrate in 200ml of ethanol, then move it into a magnetic stirring pot, add 25g of aluminum powder (diameter 20~30μm) under the condition of stirring at 90°C to coat the surface of the aluminum powder , and at the same time add 1ml of ethylenediamine (EDA) dropwise, and continue to stir until the ethanol is completely volatilized to obtain a surface-treated composite aluminum powder;

[0029] 2) Put the surface-treated composite aluminum powder prepared in step 1) in a tube furnace, and heat it to 400°C under the condition of high-purity hydrogen (the flow rate of high-purity hydrogen is 80 sccm, and the heating rate is 5°C / min) , keep warm for 1h, then heat to 600°C in a mixed atmosphere of argon and hydrogen (the flow rate of argon gas is 320 sccm, the flow rate of hydrogen g...

Embodiment 2

[0038] The preparation of a three-dimensional carbon nanophase composite reinforced aluminum-based material comprises the following steps:

[0039] 1) Dissolve 1g of bisphenol A diglycidyl ether (DGEBA) and 0.5g of nickel nitrate hexahydrate in 200ml of ethanol, then move it into a magnetic stirring pot, add 25g of aluminum powder (20~30μm in diameter) under stirring at 90°C , so that it is coated on the surface of the aluminum powder, and at the same time, 1ml of ethylenediamine (EDA) is added dropwise, and the stirring is continued until the ethanol is completely volatilized, and the surface-treated composite aluminum powder is obtained;

[0040] 2) Put the surface-treated composite aluminum powder prepared in step 1) in a tube furnace, and heat it to 400°C under the condition of high-purity hydrogen (the flow rate of high-purity hydrogen is 80 sccm, and the heating rate is 5°C / min) , keep warm for 1h, then heat to 600°C in a mixed atmosphere of argon and hydrogen (the flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com